Cigarette sheet compressing blocking and packing machine

A technology of block packing machine and tobacco sheet, which is applied in the fields of tobacco, packaging, and preparation of tobacco, etc. It can solve problems such as burnt bags, easy to mildew, and reduce equipment height, so as to improve air permeability, reduce material loss, and reduce tobacco leaf loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] Compression power machines, horizontal power cylinders, lifting power cylinders, conveyor belts, etc. that the present invention relates to are not particularly specified, and are conventional motors, air cylinders or hydraulic cylinders, and belt conveyors.

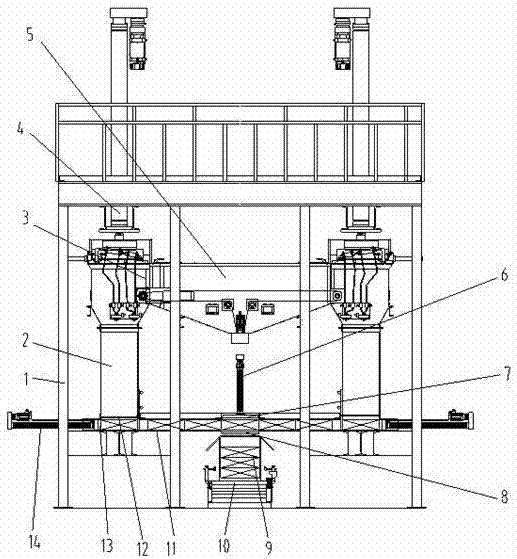

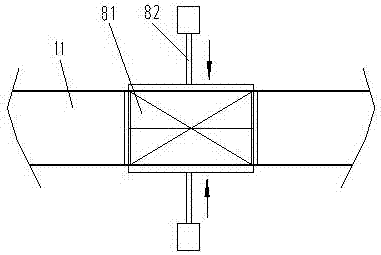

[0015] The cigarette sheet compression block packing machine provided by the present invention comprises a frame 1, a vertical material box 2 arranged on the frame 1, the upper side of the vertical material box 2 is provided with a feed port 3, and the top is provided with a The bottom of the compression power machine 4 is provided with an open and close base plate 12, wherein: the bottom of the vertical material box 2 is provided with a blanking plate 9, one end of the blanking plate 9 is provided with a horizontal pusher 13 connected to a horizontal power cylinder 14, and the other One end is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com