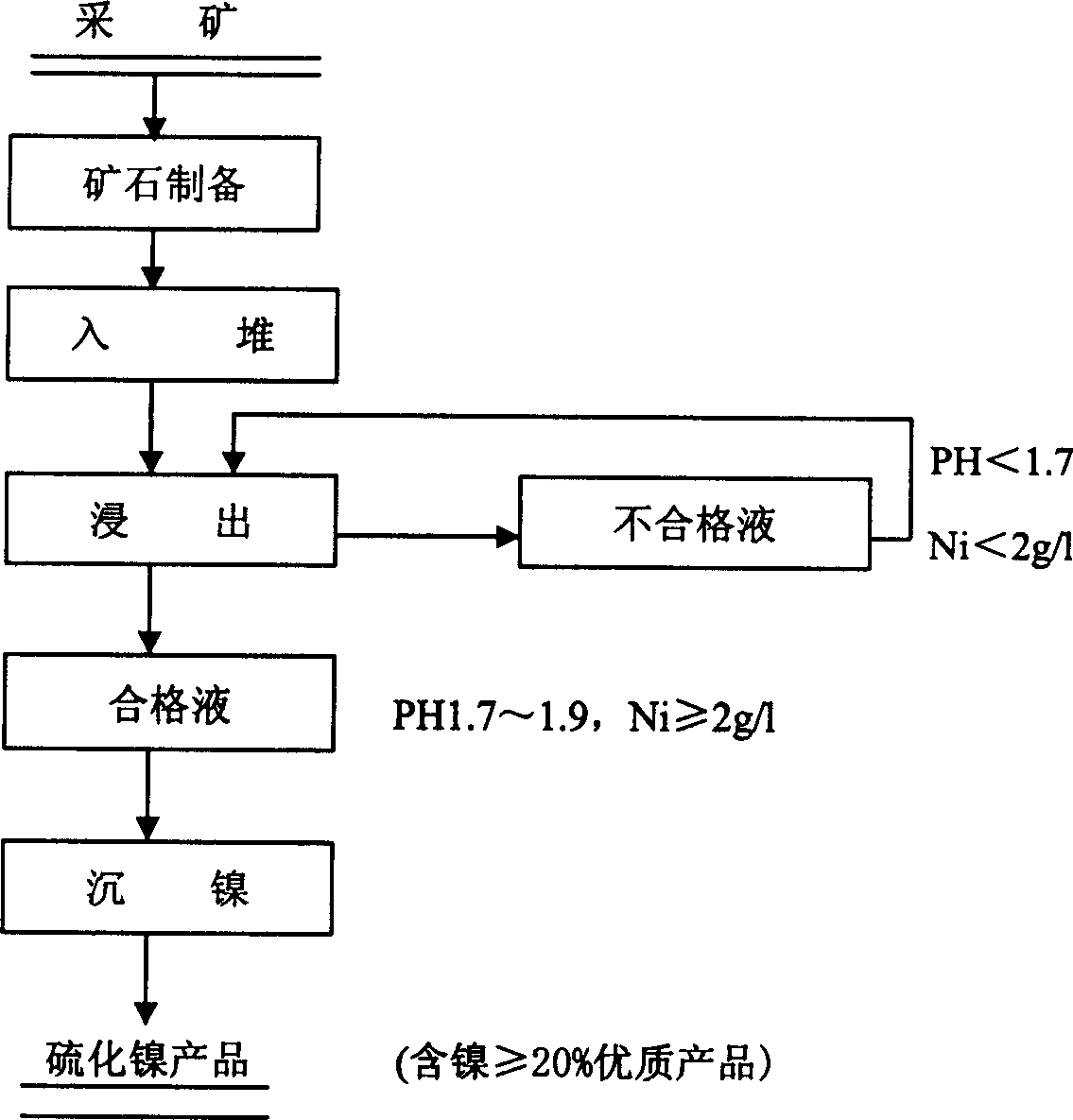

Method of bulk infusion extracting nickel cobalt from low grade red soil nickel ore

A laterite nickel ore, low-grade technology, which is applied in the field of heap leaching and nickel extraction, can solve the problems of unsuitable processing of low-grade laterite nickel ore, small adaptable resource range and high production cost, and achieves wide utilization range of mineral resources, low investment, and high production cost. The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A. After the ore is mined, crush the ore with a particle size greater than 2cm, and control the average particle size below 2cm;

[0026] B. Put the ore with a particle size above 100 mesh to 1.5cm directly into the pile, and at the same time mix the ore with a particle size of less than 100 mesh and a particle size larger than 1.5cm according to a mass ratio of 0.5:1 and put it into the pile. Loose piles of ore heaps to improve the permeability of ore heaps;

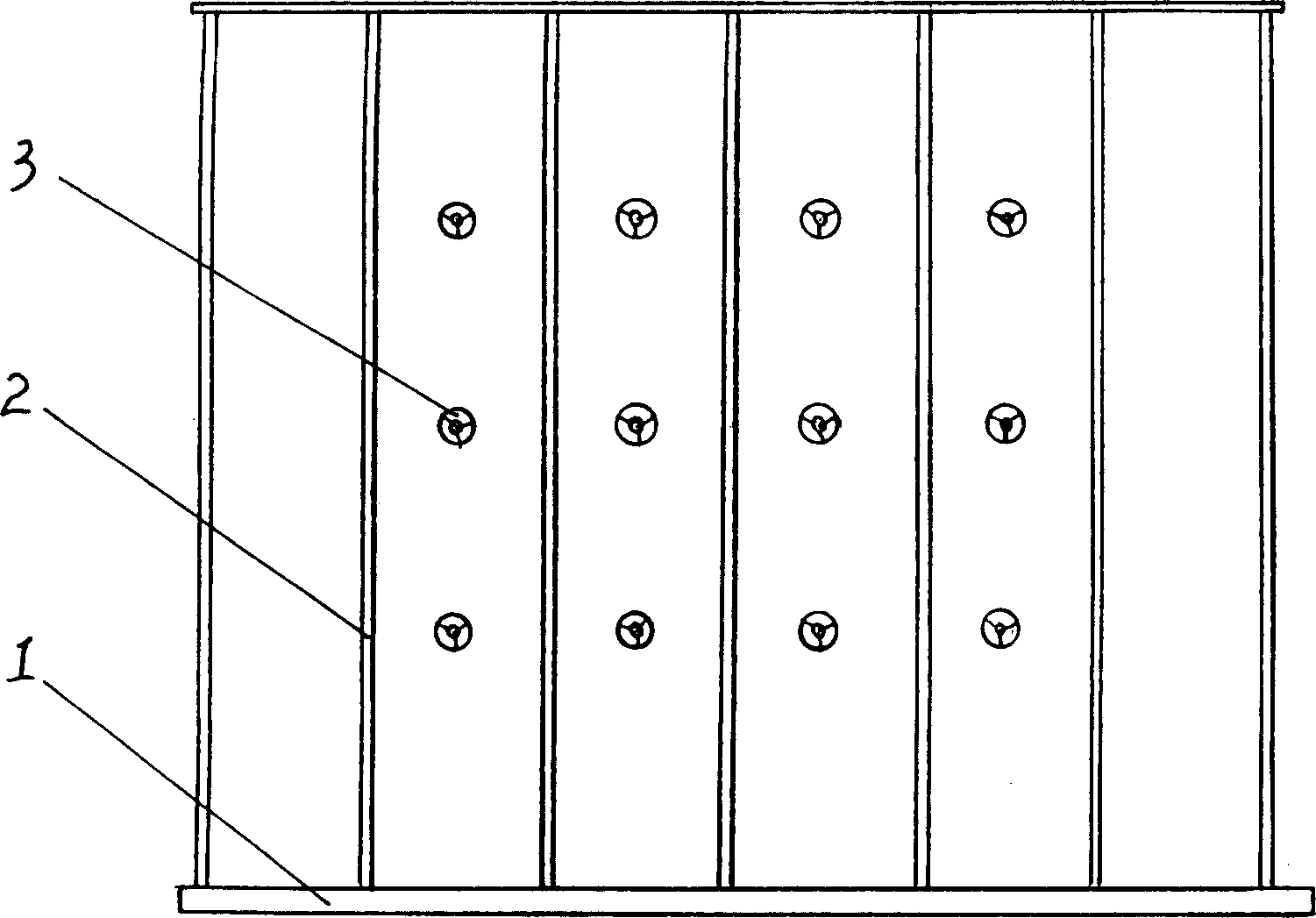

[0027] C. Prepare sulfuric acid aqueous solution according to the requirements of spray concentration of 5%, and spray intensity of 15L / m 2 The amount of .h, the sulfuric acid aqueous solution is sent to each sprinkler installed on the top of the ore heap and each drip irrigation pipe to realize the spraying and dripping leaching of the ore heap, and a sprinkler is set every 2-3 square meters on the top of the ore heap. Set a drip irrigation pipe every 30-40cm on the top and side of the ore pile;

[0028] D. Co...

Embodiment 2

[0031] A. After the ore is mined, crush the ore with a particle size greater than 2cm, and control the average particle size below 2cm;

[0032] B. Put the ore above 100 mesh to 1.5cm into the pile directly, and at the same time, mix the ore with a particle size of less than 100 mesh and a particle size larger than 1.5cm according to the mass ratio of 0.8:1 and put it into the pile. Loose piles of ore heaps to improve the permeability of ore heaps;

[0033] C. Prepare hydrochloric acid aqueous solution according to the requirement that the spray concentration is 18%, and the spray intensity is 30L / m 2 The amount of .h, the hydrochloric acid aqueous solution is sent into the nozzles and drip irrigation pipes arranged on the top of the ore heap to realize the spraying and dripping of the ore heap. A nozzle is set every 2-3 square meters on the top of the ore heap. Set a drip irrigation pipe every 30-40cm on the top and side of the ore pile;

[0034] D. Collect the leachate aft...

Embodiment 3

[0037] A. After the ore is mined, crush the ore with a particle size greater than 2cm, and control the average particle size below 2cm;

[0038] B. Put the ore above 100 mesh to 1.5cm directly into the heap, and at the same time mix the ore with a particle size of less than 100 mesh and more than 1.5cm in a mass ratio of 0.7:1 and put it into the heap. After building the heap, use an excavator to carry out Loose piles of ore heaps to improve the permeability of ore heaps;

[0039] C. Prepare a mixed aqueous solution of sulfuric acid and hydrochloric acid according to the requirement that the spray concentration is 10%. The ratio of sulfuric acid and hydrochloric acid is 1:2, and the spray intensity is 22L / m 2 .h, send the mixed aqueous solution into the nozzles and drip irrigation pipes arranged on the top of the ore heap to realize the spraying and dripping leaching of the ore heap, and set a nozzle every 2-3 square meters on the top of the ore heap. Set a drip irrigation pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com