Misunderstanding prevention resistance random access memory and production method thereof

A resistive variable memory and resistive variable technology, applied in the field of memory, can solve problems such as instability and easy misreading, and achieve the effects of excellent anti-fatigue characteristics, stable resistance changes, and significant switching effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

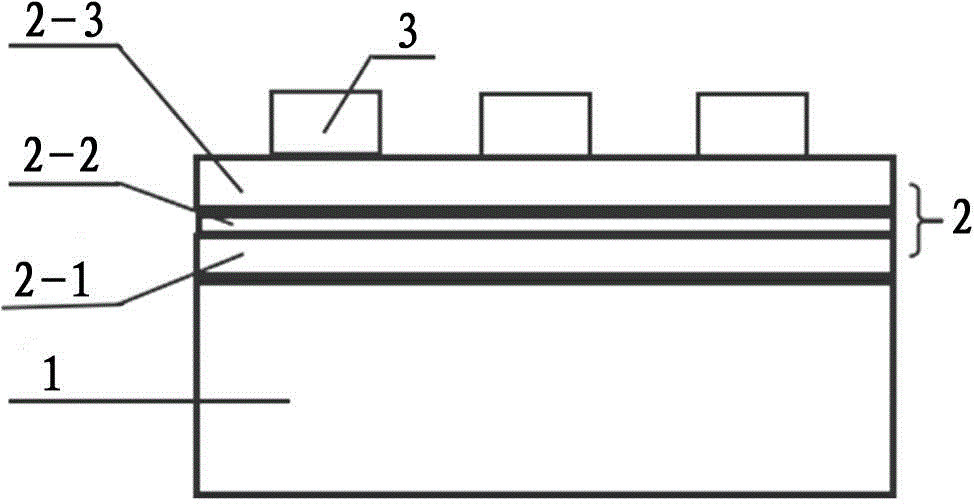

[0030] Embodiment 1, a resistive memory that avoids misreading.

[0031] Such as figure 1 As shown, the anti-misreading resistive memory provided by the present invention has a structure including a substrate 1 at the bottom, a resistive dielectric layer 2 on the substrate 1 and an electrode film layer 3 on the resistive dielectric layer 2 . Substrate 1 is Pt / Ti / SiO 2 / Si substrate, “Pt / Ti / SiO 2 / Si" means that the bottom is Si, Si is SiO 2 , SiO 2 Ti is above Ti, and Pt is above Ti. Therefore, the Pt film layer is the topmost layer of the substrate 1 , and the resistive variable medium layer 2 is located on the Pt film layer of the substrate 1 .

[0032] The resistive variable medium layer 2 is composed of three layers stacked in sequence, from bottom to top are the first layer of bismuth ferrite film layer 2-1, the second layer of bismuth ferrite film layer 2-2 doped with silver, and the third layer of ferrite film layer 2-2. Bismuth film layer 2-3. The thickness of th...

Embodiment 2

[0034] Embodiment 2, a preparation method of a resistive variable memory that avoids misreading.

[0035] The preparation method of the resistive variable memory which avoids misreading provided by the present invention comprises the following steps:

[0036] (1) Forming a resistive dielectric layer on the substrate.

[0037] ①. Selection and processing of substrate materials

[0038] Choose Pt / Ti / SiO 2 / Si as the substrate (or substrate), put the substrate in acetone and clean it ultrasonically for 10 minutes, then put it in alcohol and clean it ultrasonically for 10 minutes, then take it out with clips and put it in deionized water and clean it ultrasonically for 5 minutes , then removed, with nitrogen (N 2 ) and blow dry.

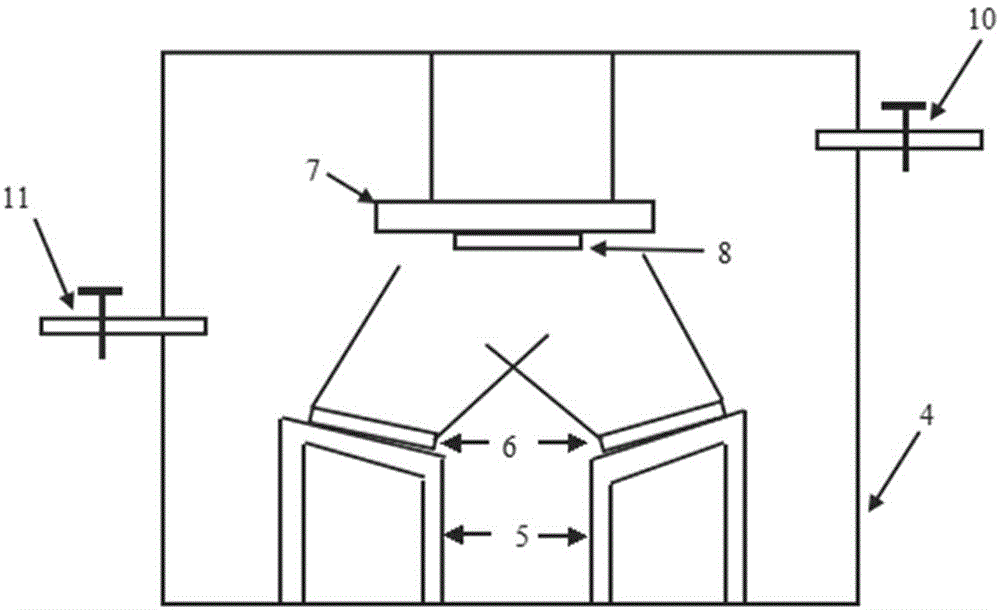

[0039] ②, put in the substrate, vacuumize

[0040] Such as figure 2 As shown, open the chamber 4 of the magnetron sputtering equipment, take out the tablet press table 8, polish it with sandpaper until it shines, clean the polished waste and organ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com