Piezoelectric driving device of functional gradient structure and its preparing method

A technology of piezoelectric actuators and functional gradients, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve Expensive, increase production costs, limit wide application and other issues, to achieve the effect of increased fracture strength, improved mechanical properties and service characteristics, improved working stability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

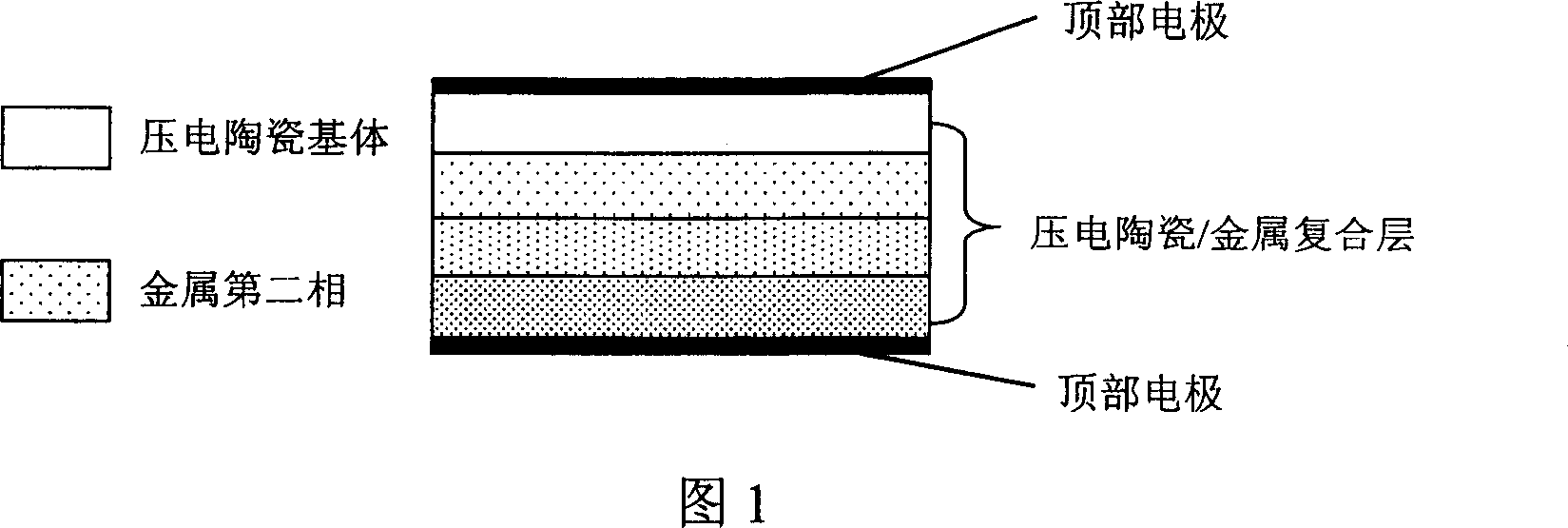

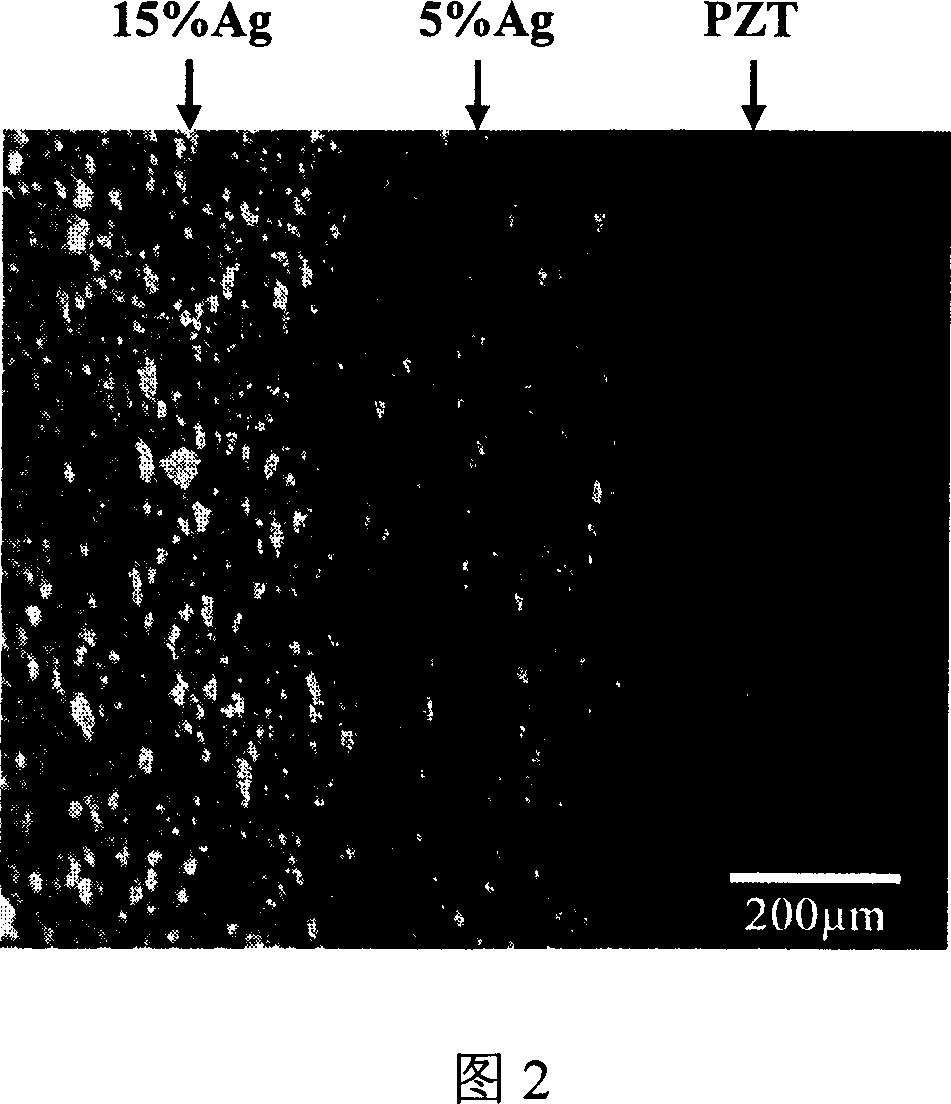

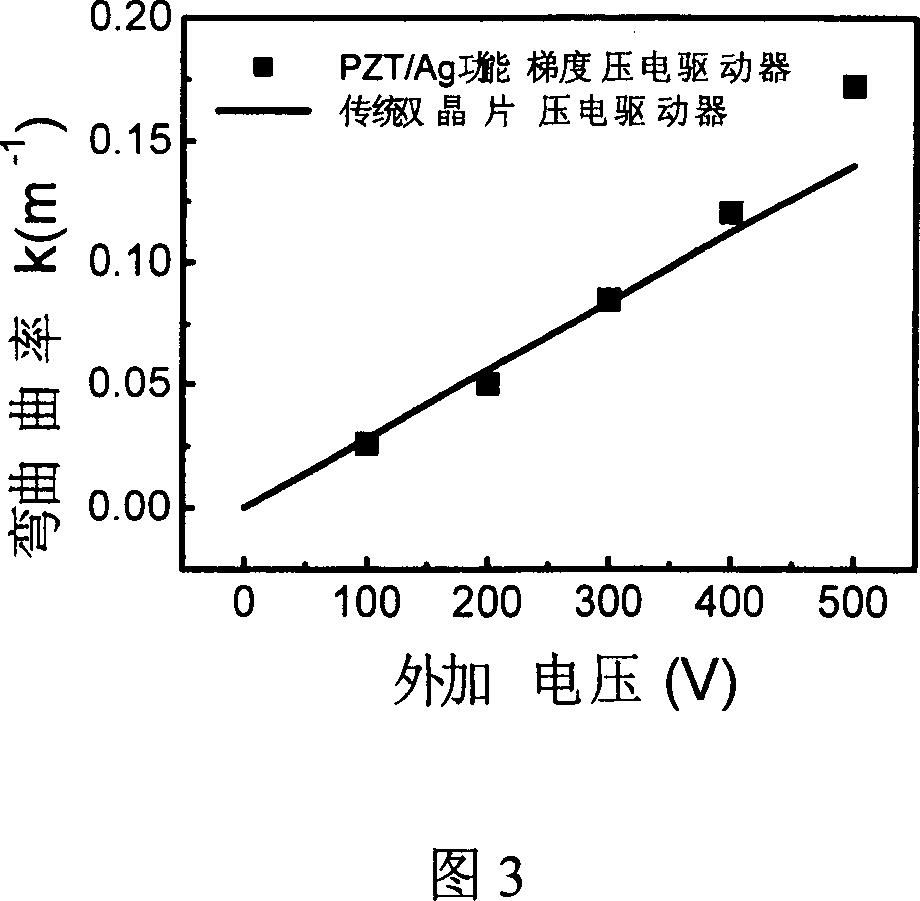

[0022] Commercially available PZT powder (Japan Sakai Chemical Industry Co., Ltd., Zr / Ti molar ratio is 0.516 / 0.484, and the average particle diameter is 0.97 micron) and Ag powder (Japan High Purity Chemical Company, the purity is 99.9wt%, and the average particle diameter is 2.0 microns) as raw materials, sintered at 1200 °C to prepare a PZT / 5%Ag / 15%Ag three-layer composite functionally gradient piezoelectric actuator, the thickness of each layer is about 0.33 mm, and the size of the cantilever beam is 12×2× 1 mm.

Embodiment 2

[0024] Commercially available PZT powder (Japan Sakai Chemical Industry Co., Ltd., Zr / Ti molar ratio is 0.516 / 0.484, and the average particle diameter is 0.97 micron) and Ag powder (Japan High Purity Chemical Company, the purity is 99.9wt%, and the average particle diameter is 2.0 microns) as raw materials, sintered at 1160 ° C to prepare a PZT / 1%Ag / 5%Ag / 10%Ag / 15%Ag five-layer composite functional gradient piezoelectric actuator, each layer thickness is about 0.4 mm, The cantilever beam dimensions are 15 x 3 x 2 mm.

Embodiment 3

[0026] Commercially available PZT powder (Japan Sakai Chemical Industry Co., Ltd., Zr / Ti molar ratio is 0.516 / 0.484, and the average particle diameter is 0.97 micron) and Ag powder (Japan High Purity Chemical Company, the purity is 99.9wt%, and the average particle diameter is 2.0 microns) as raw materials, sintered at 900 ° C to prepare a seven-layer composite functional gradient piezoelectric actuator of 1%Ag / 3%Ag / 5%Ag / 10%Ag / 5%Ag / 3%Ag / 1%Ag , the thickness of each layer is about 0.2 mm, and the size of the cantilever beam is 8×2×1.5 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com