Ceramic laminated device and method for manufacturing same

A ceramic and multilayer technology, applied in the direction of multilayer capacitors, multilayer circuit manufacturing, printed circuit manufacturing, etc., can solve the problems of easy loss, lower device Q value, electrode width or thickness smaller than the design value, etc. Q value, excellent characteristics, and the effect of small variation in characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

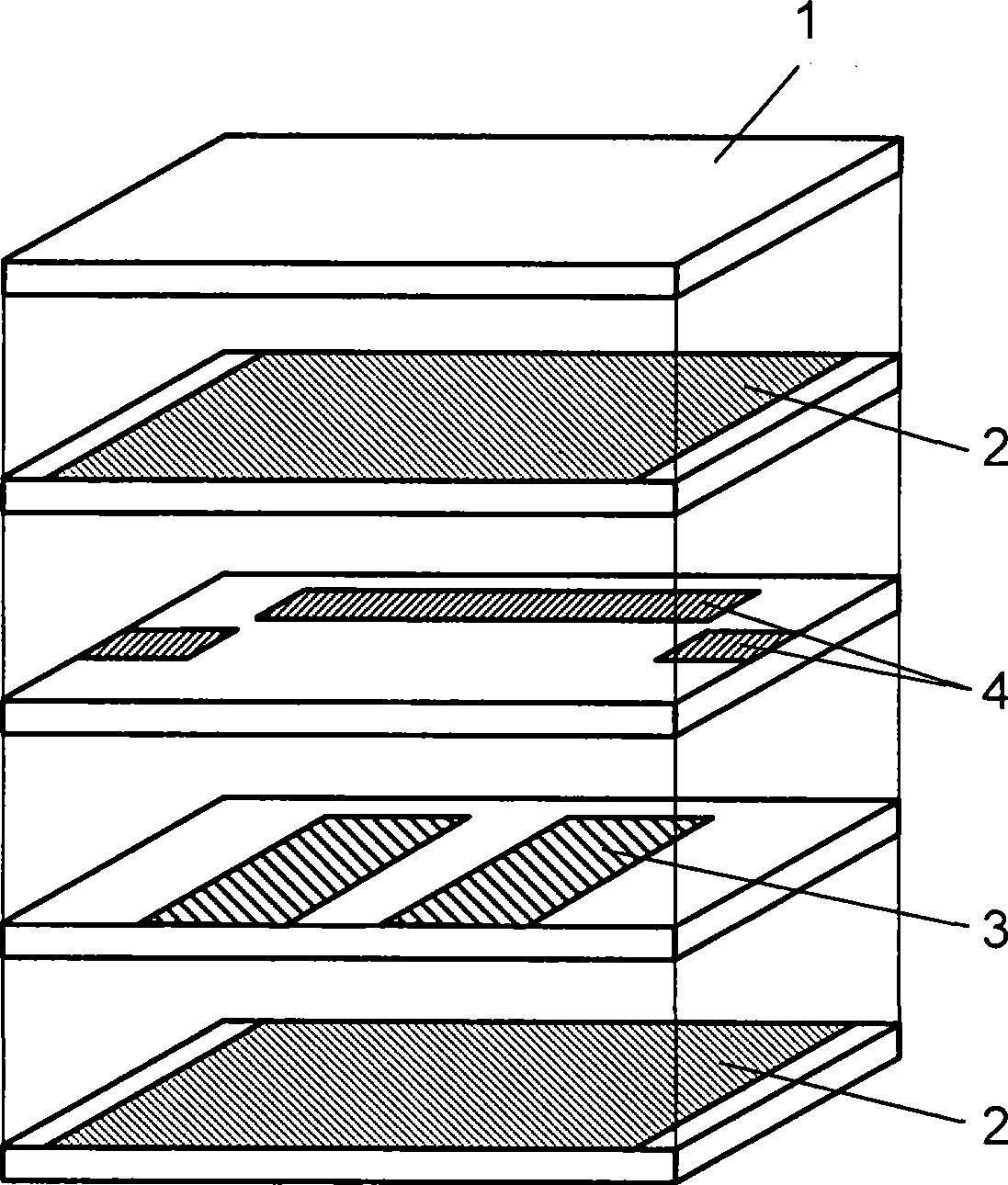

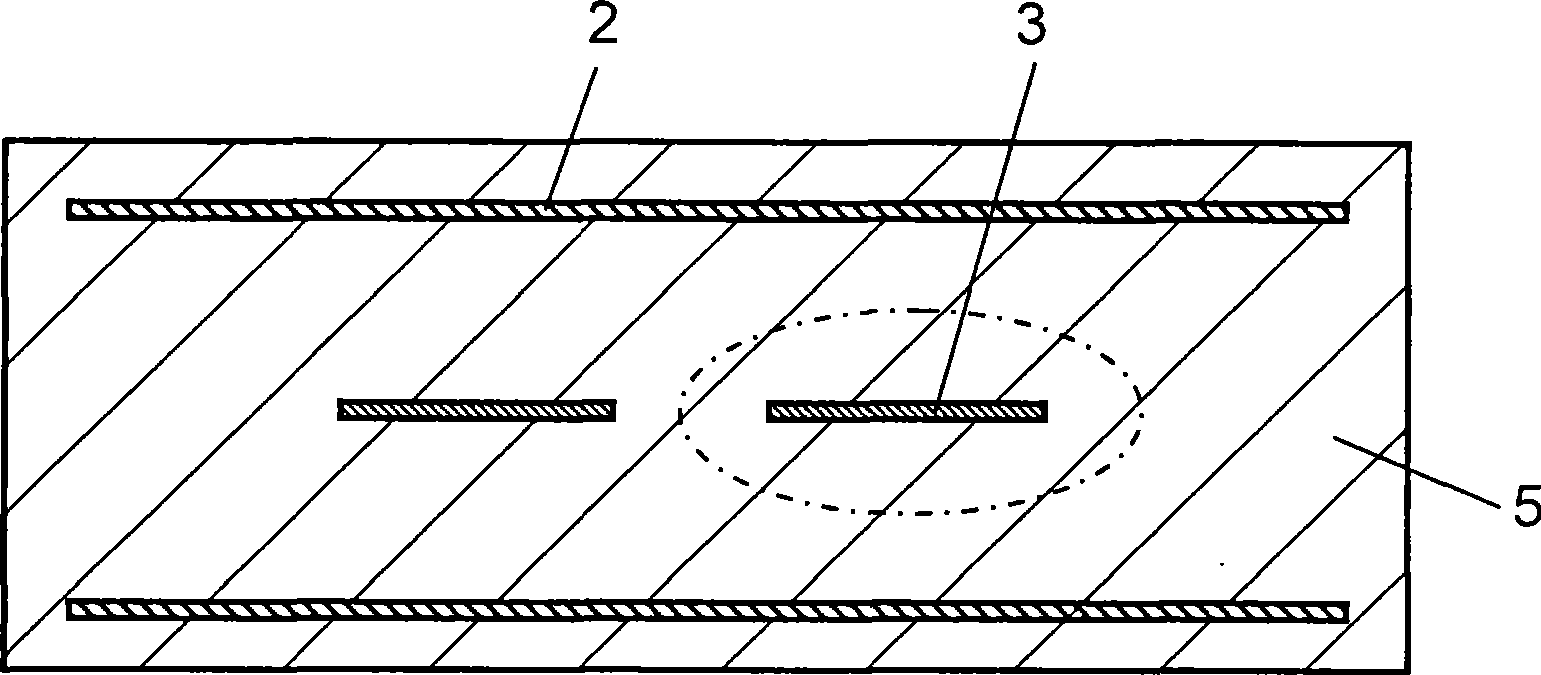

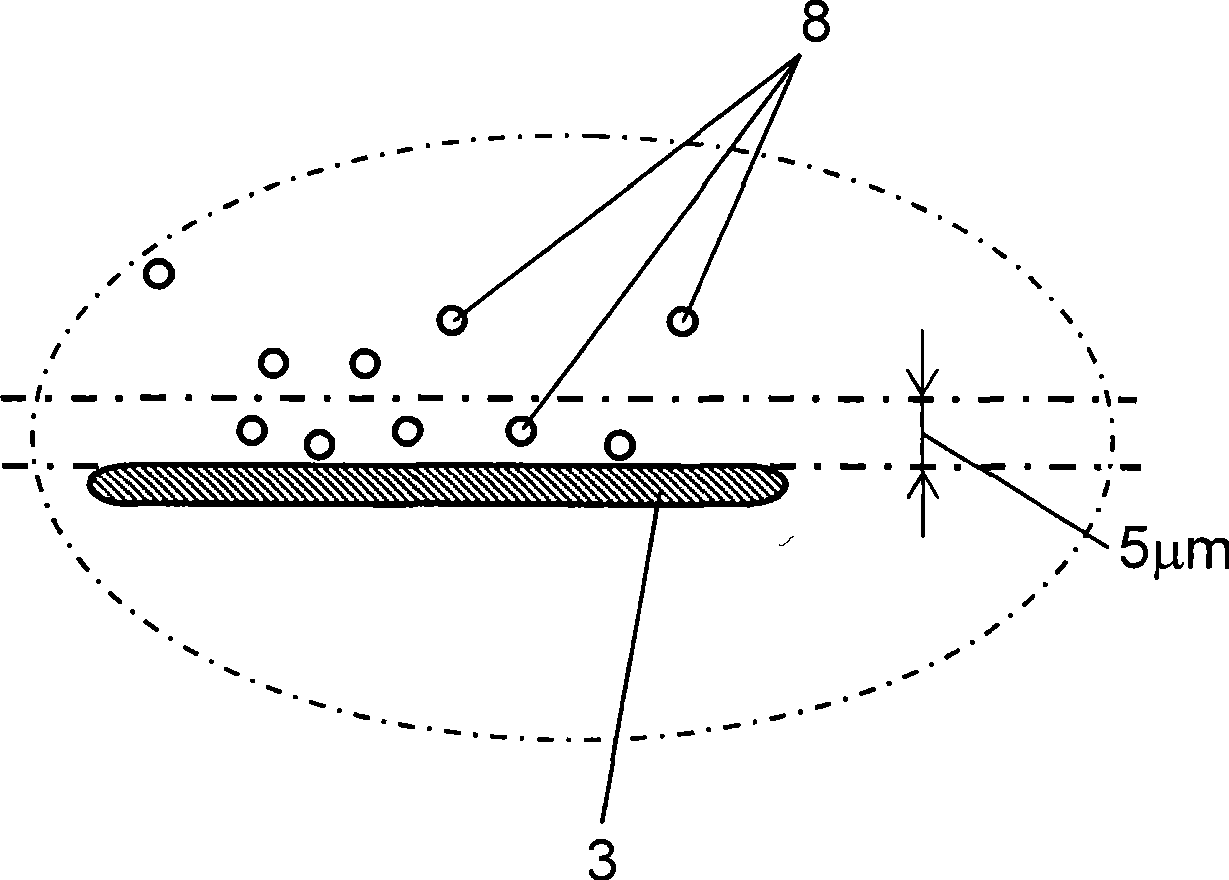

[0025] Hereinafter, a ceramic multilayer device and a manufacturing method according to one embodiment of the present invention will be described.

[0026] BaCO with high chemical purity (99% by weight or more) is used as the first component of the raw material 3 、Nd 2 o 3 、TiO 2 and Bi 2 o 3 . When xBaO-yNd 2 o 3 -zTiO 2 -wBi 2 o 3 When (x+y+z+w=100, x, y, z, and w are molar ratios) represent the composition of each component, the preferred composition range is 12≤x≤16, 12≤y≤16, 65≤z≤ 69. 2≤w≤5. In addition, although Nd is used here 2 o 3 As rare earth oxides, but oxides other than Nd such as La 2 o 3 、Sm 2 o 3 and other rare earth oxides. In addition, a part of Nd may be replaced with other rare earth elements. The above powder was mixed with pure water in a ball mill for 18 hours. After mixing, the slurry was dried, placed in an alumina crucible, and calcined at a temperature of 1200° C. to 1400° C. for 2 hours. The calcined powder was roughly pulverize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com