Ag electrode paste, solar battery cell, and process for producing the solar battery cell

A technology for electrode paste and solar cells, applied to electrical components, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problem of hindering the ohmic contact between busbar electrodes and Si substrates, reducing the conversion efficiency of solar cells, and having no Point out the actual situation and other issues to achieve the effect of high reliability, high conversion efficiency, and reduced line resistance

Active Publication Date: 2010-08-18

MURATA MFG CO LTD

View PDF2 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, as in Patent Document 1 above, in the case of a solar battery cell having two layers of bus bar electrodes (light-receiving surface side electrodes) made of Ag electrodes, the glass frit contained in the Ag electrode paste for forming the upper layer bus bar electrodes is Flows on the surface of the bus bar electrode on the upper layer side during electrode firing, for example, in the case of welding lead wires to the bus bar electrode on the upper layer side, there is a problem that the weld wettability is hindered

In addition, when the glass frit contained in the Ag electrode paste for forming the bus bar electrode on the upper layer side flows too much to the bus bar electrode on the lower layer side, the ohmic contact between the bus bar electrode on the lower layer side and the Si substrate is hindered, and the solar battery cell Conversion efficiency may decrease

Furthermore, there is a problem that, when the Ag electrode paste is fired, the bus bar electrodes on the upper layer will be damaged before the gas (decomposed gas of binder, combustion gas, etc.) generated from the bus bar electrodes (Ag electrodes) on the lower layer side is exhausted When the sintering is completed, bubbles are generated due to the above-mentioned gas

In addition, the electrode paste of Patent Document 2 relates to an Ag / Al electrode, which does not provide useful information on the lead-free glass frit used in the Ag electrode paste used in this application, and is used as the light-receiving surface side electrode of the solar cell unit. In the case of forming an Ag electrode, the method of obtaining a solar cell unit with better characteristics is not indicated in Patent Document 2.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

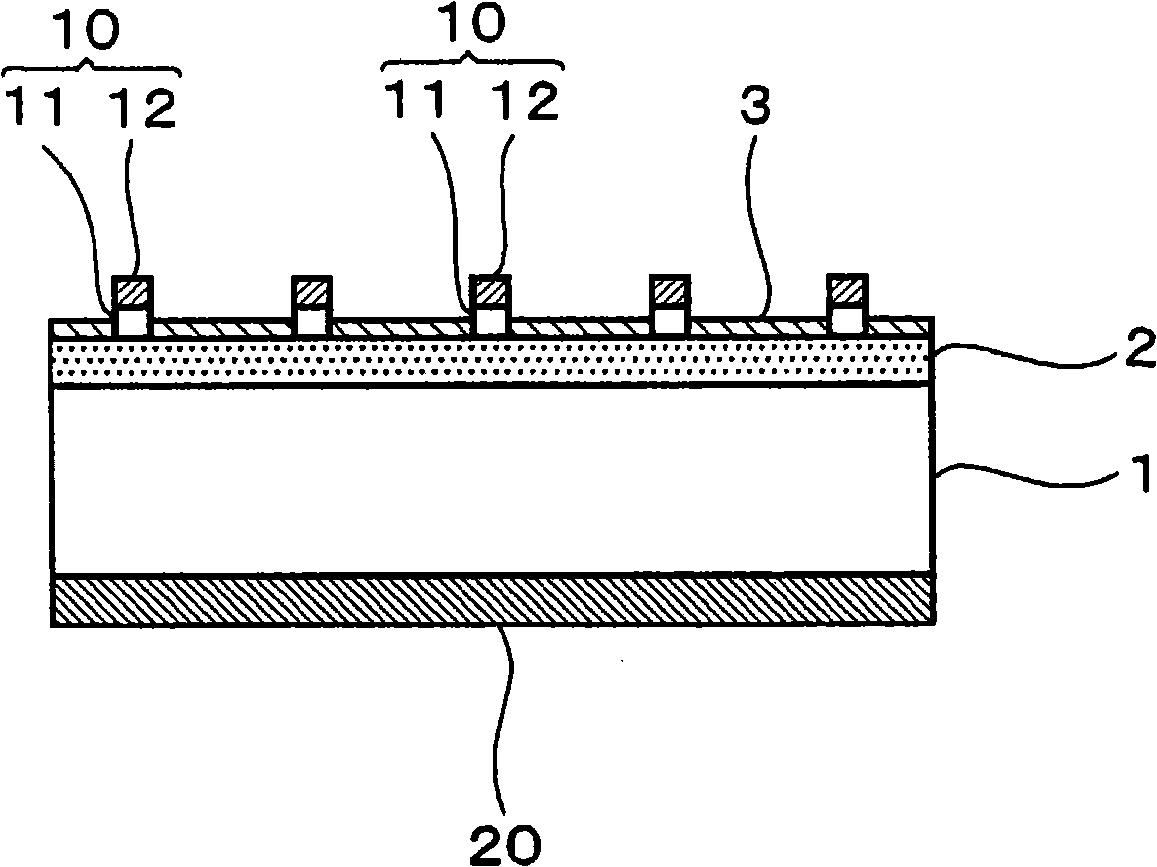

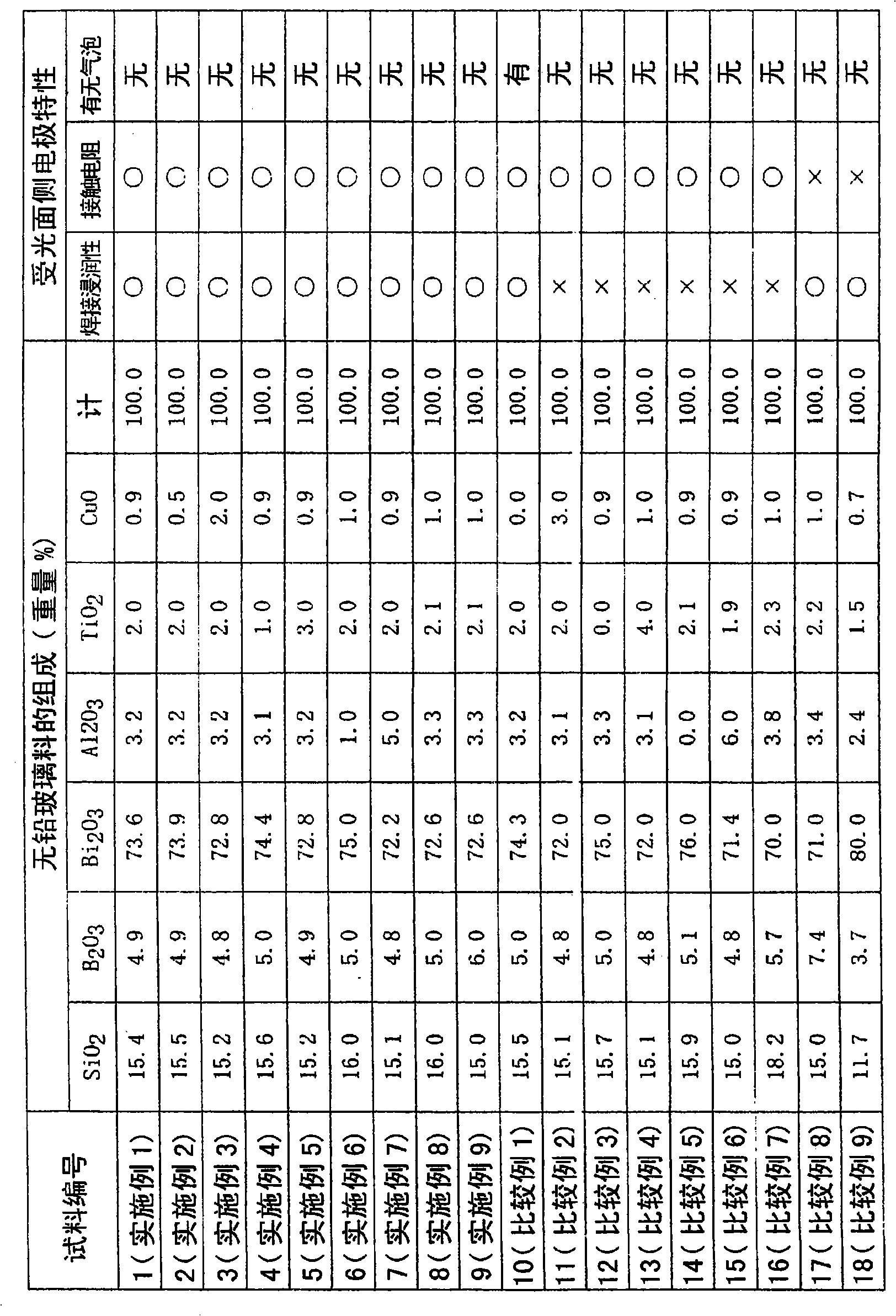

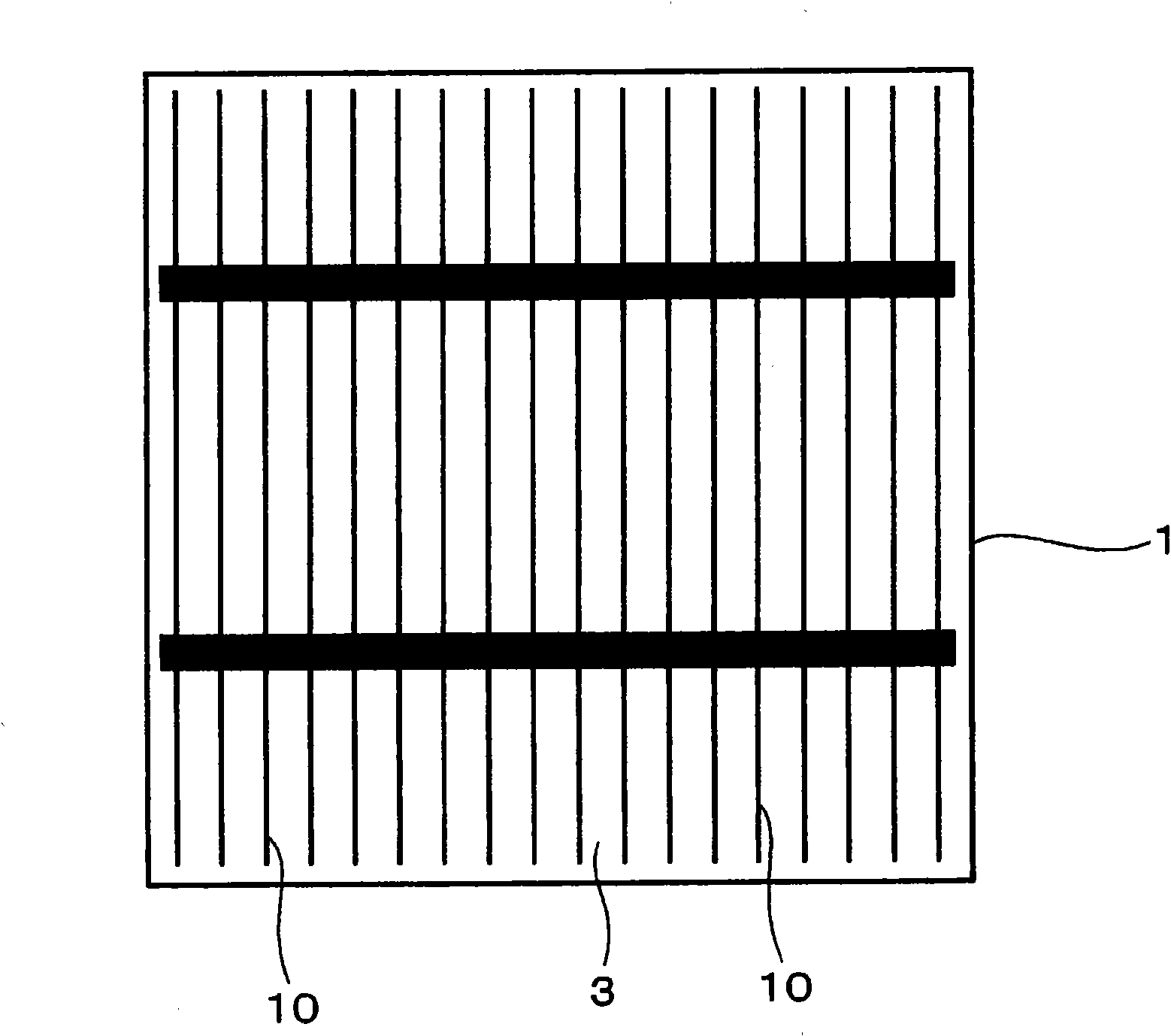

This invention provides an Ag electrode paste for light receiving face-side electrode formation, which can provide a solar battery cell with a high conversion efficiency and provided with a light receiving face-side electrode having low line resistance, and a solar battery cell having good characteristics producing using the Ag electrode paste, and a process for producing the solar battery cell. The Ag electrode paste for use in the formation of a light receiving face-side electrode (10) comprises (a) Ag particles, (b) an organic vehicle, and (c) a lead-free glass frit comprising SiO2: 13 to 17% by weight, B2O3; 0 to 6% by weight, Bi2O3: 65 to 75% by weight, Al2O3: 5% by weight, TiO2: 1 to 3% by weight, and CuO: 0.5 to 2% by weight. The Ag electrode paste is used in the formation of a second electrode in a light receiving face-side electrode (10) comprising a first electrode (11) and a second electrode (12) provided on the first electrode.

Description

technical field The present invention relates to an Ag electrode paste, a solar battery cell using the paste to form a light-receiving surface-side electrode, and a method for manufacturing a solar battery cell including a step of using the Ag electrode paste to form a light-receiving surface-side electrode. Background technique As a current manufacturing method of a solar cell unit, after forming a PN junction on a semiconductor substrate, a comb-shaped interdigital electrode is formed on at least one main surface of the semiconductor substrate, and a solar cell electrode connected to the busbar electrode of the interdigital electrode is disclosed. A method of manufacturing a battery cell in which a bus bar electrode having a two-layer structure is formed by printing a conductive paste twice and firing it (see FIGS. 1 to 4 of Patent Document 1). In this solar cell manufacturing method, in the two-layer bus bar electrodes (Ag electrodes in the embodiment) on the surface of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01L31/04

CPCC03C3/064H01B1/16H05K1/092H01L31/022433Y02E10/50C03C8/18

Inventor 川口义博

Owner MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com