Silicon solar cell and manufacturing method thereof

A technology of silicon solar cells and silicon wafers, applied in the manufacture of circuits, electrical components, final products, etc., can solve the problems of small photovoltaic power generation, high cost and large-scale application of photovoltaic power generation, achieve small contact resistance, avoid battery current drop, The effect of preventing undercutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

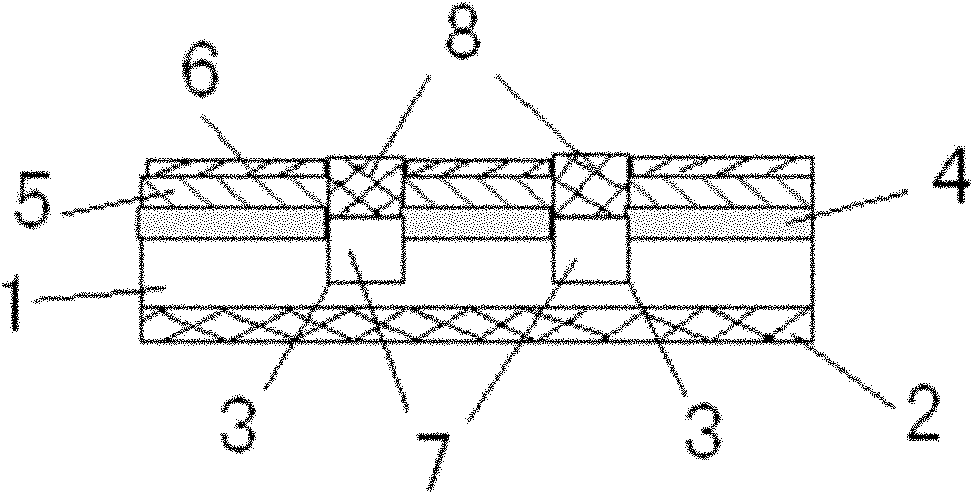

[0029] Such as figure 1 As shown, the silicon solar cell of the present invention includes a silicon wafer 1, and the back side of the silicon wafer 1 is provided with a Ti / Pd / Ag electrode 2 to form a back electrode; the front side of the silicon wafer 1 is uniformly provided with two grooves 3 by etching, and N-type silicon 4 , oxide layer 5 and ITO (indium tin oxide) film 6 are sequentially arranged on the front of silicon wafer 1 , and the shapes of N-type silicon 4 , oxide layer 5 and ITO film 6 are all corresponding to silicon wafer 1 . In the two grooves 3, N + Type silicon 7 and Ti / Pd / Ag electrode 8, two Ti / Pd / Ag electrodes 8 form the positive electrode.

[0030] In the above embodiment, the silicon wafer 1 is a P-type radial double-sided polished silicon wafer with a resistivity of 3 Ωcm and a thickness of 320 μm.

[0031] In the above-men...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet resistance | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com