Solar cell structure with anti-potential induced degradation (PID) effect and production method of solar cell structure

A technology of solar cells and production methods, applied in the manufacture of circuits, electrical components, final products, etc., can solve problems such as difficult control, difficult control of oxide layer growth, and not very dense oxide layer, and achieve good effect and passivation Better effect, good passivation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

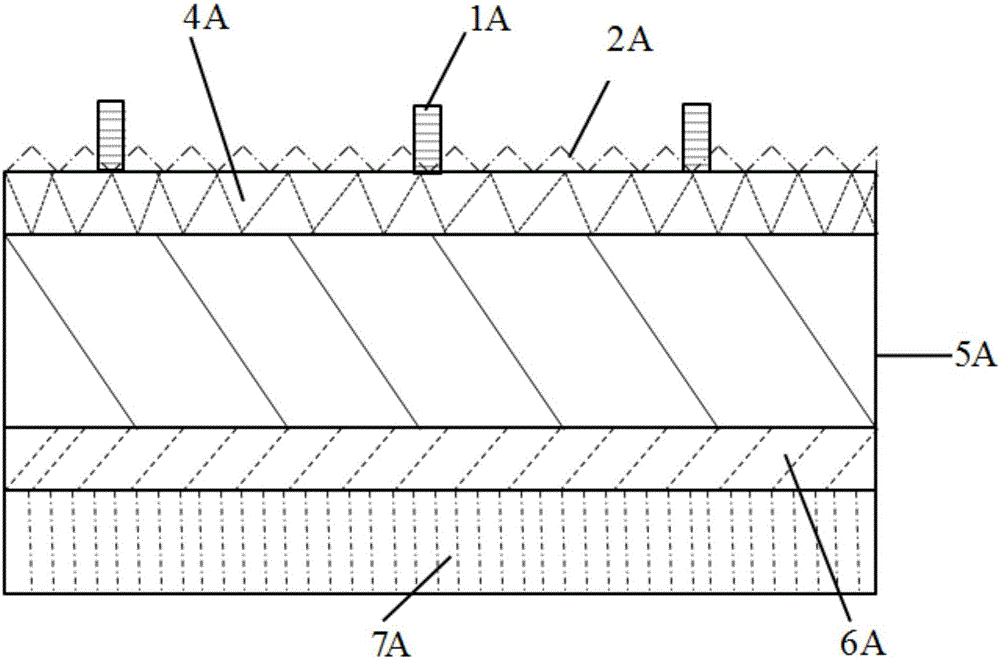

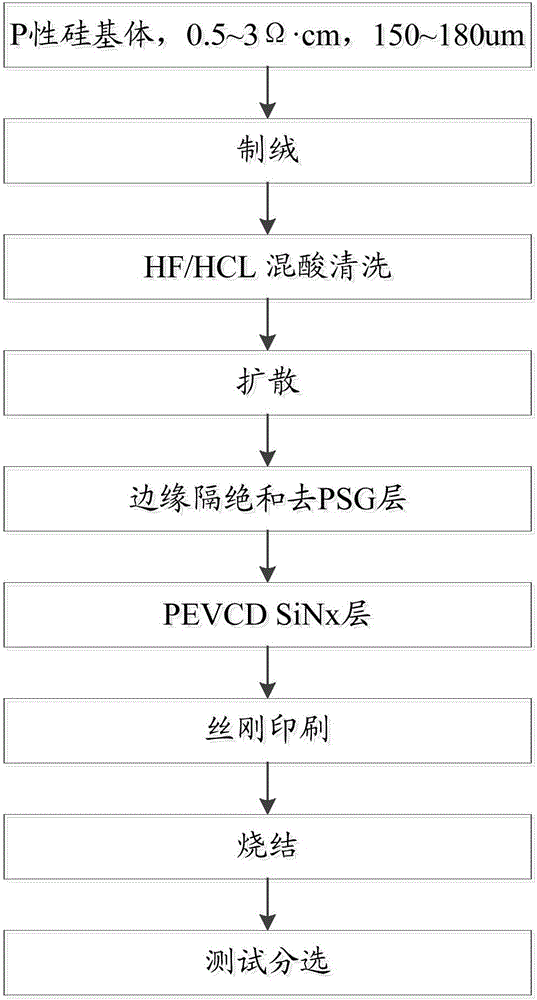

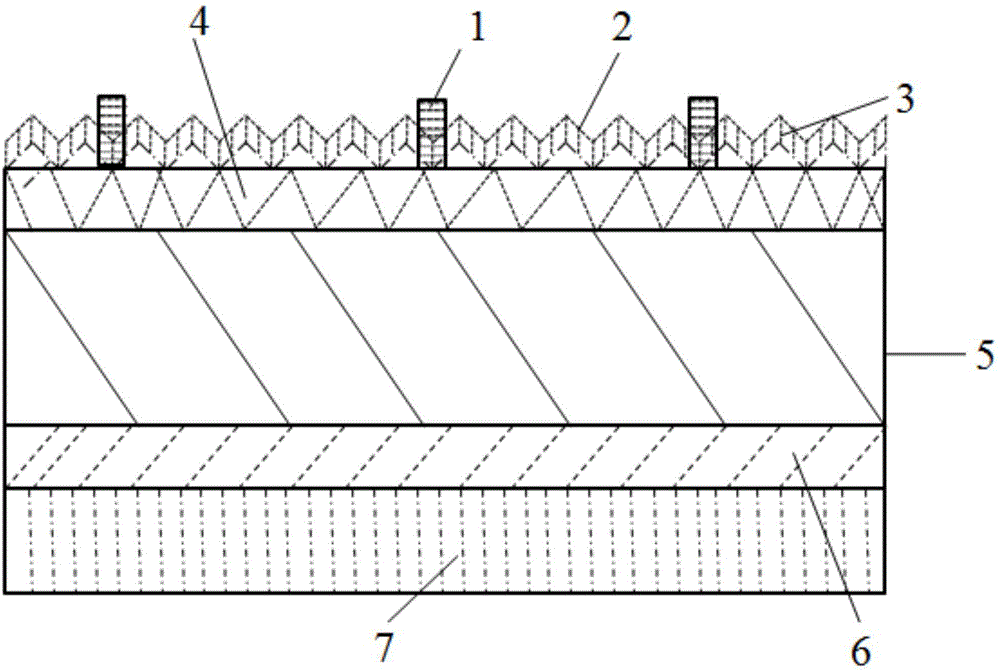

[0088] Such as Figure 1~2 Said, the anti-PID effect solar cell structure and production method are as follows: attach P+ layer 6 on aluminum back plate 7, select traditional P-type crystal silicon substrate 5, under the environment of alkaline solution, carry out pyramid suede The preparation of the P-type crystalline silicon substrate is put into the mixed acid solution of HF / HCl for pickling to remove the residual metal impurity ions on the surface of the P-type crystalline silicon substrate; then it is placed in a high-temperature quartz diffusion furnace for high-temperature diffusion, Prepare the N-type layer diffusion layer 4; remove the edge N-type layer of the diffused P-type crystalline silicon substrate 5, and remove the surface phosphosilicate glass layer, that is, the etching process; the etche...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com