Method for preparing solar cell silver wire grid electrode based on photolithographic mask method and liquid phase method

A solar cell and grid electrode technology, applied in the application field, can solve the problems of increasing the recombination probability of surface emitter carriers, increasing the reflectivity of the front surface to incident light, reducing the efficiency of the emitter performance cell, and achieving pattern and size Flexible and variable, the effect of improving carrier collection efficiency, good light transmittance and electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

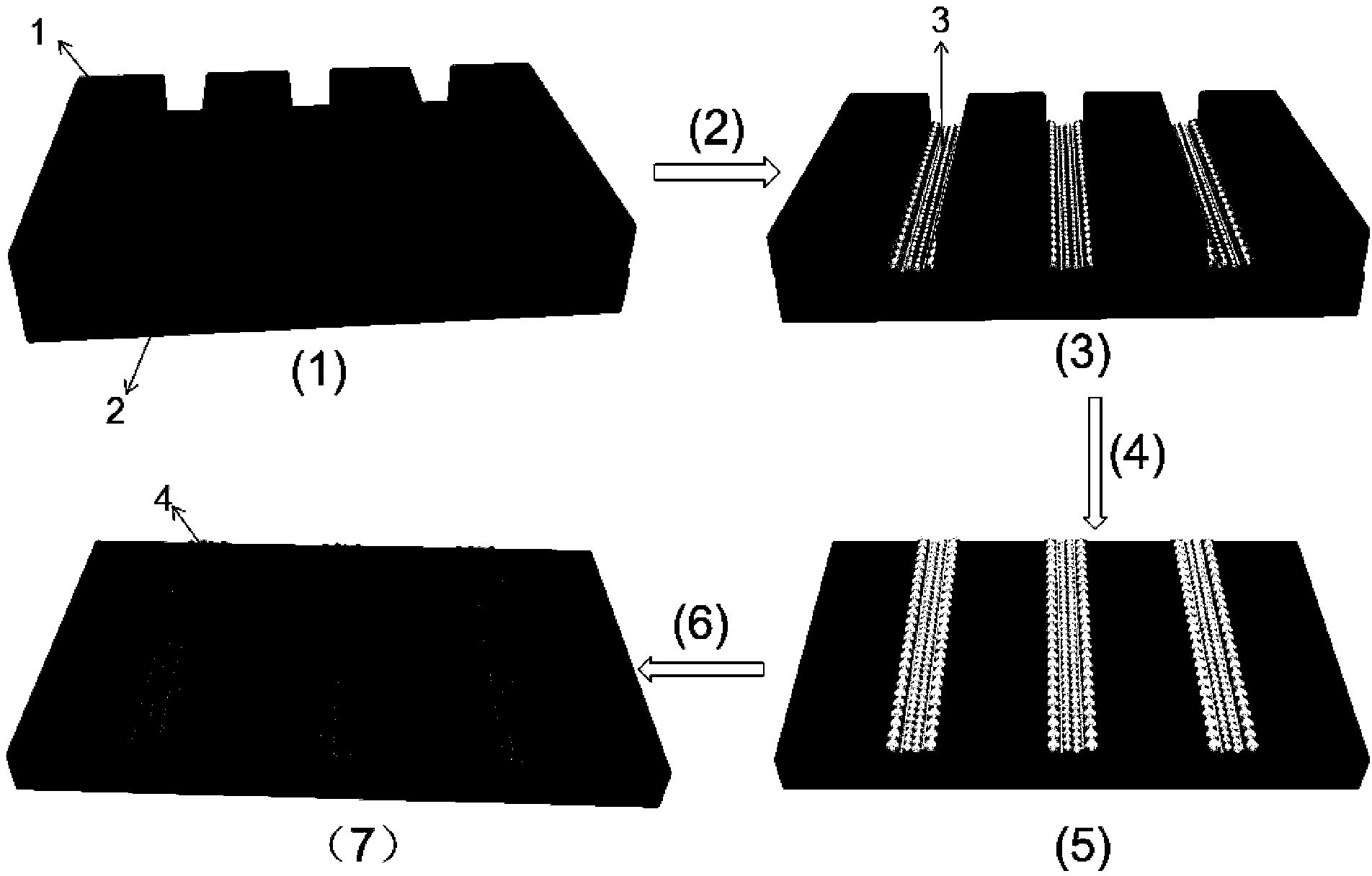

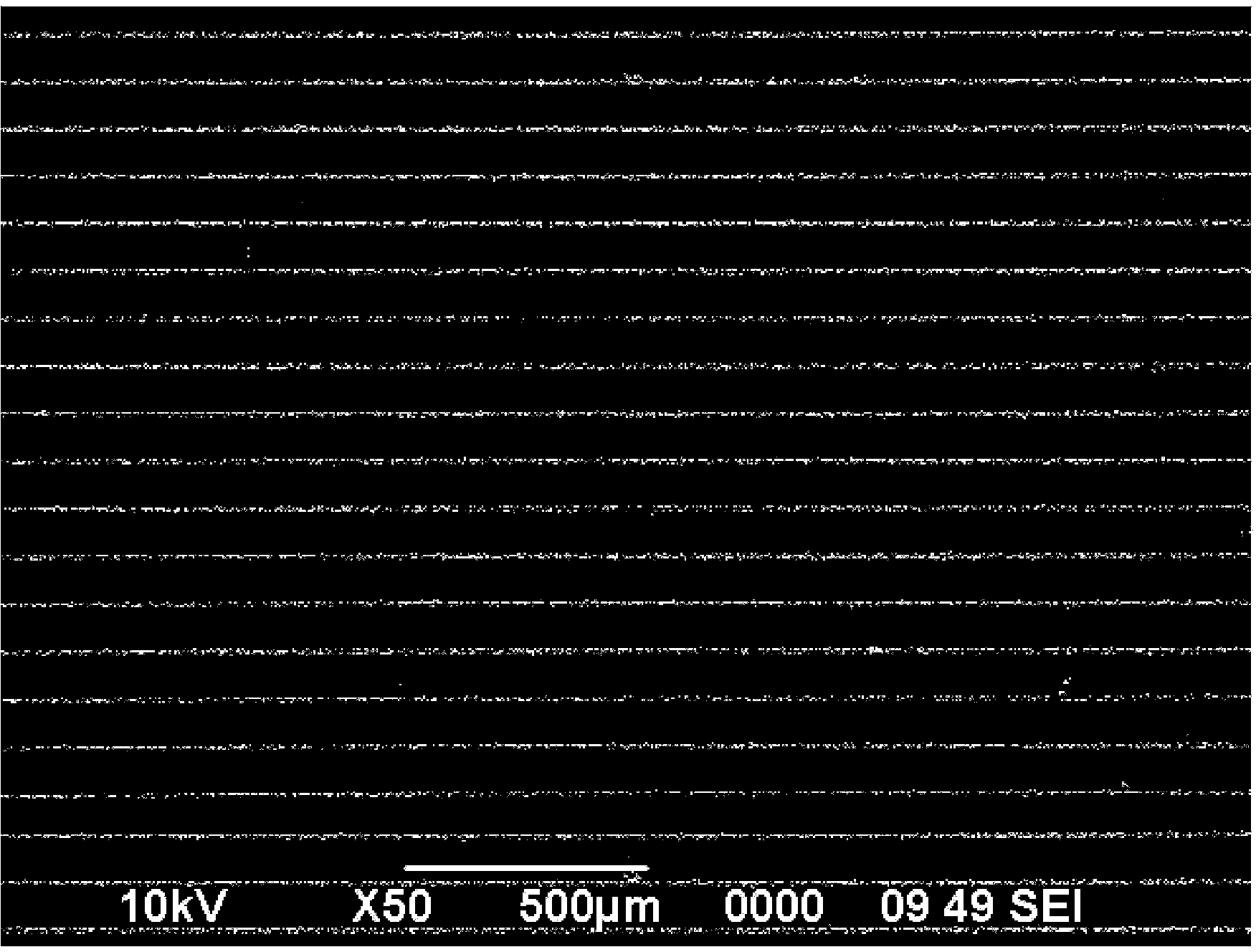

[0045] The preparation method for preparing solar cell silver wire grid electrodes on the surface of polished silicon substrate based on photolithography mask method and liquid phase method provided by this embodiment, such as figure 1 As shown, among them (1) making a photoresist template; (2) a chemical reaction occurs between the silicon substrate and the mixed solution of silver nitrate and hydrofluoric acid; (3) producing silver particles on the exposed silicon substrate between the photoresists deposition to form silver grid lines. like figure 2 (4) Remove the photoresist on the surface of the silicon substrate with a film remover; (5) Leave grid lines formed by closely arranged silver particles on the surface of the silicon substrate; (6) High temperature annealing treatment. (7) The closely arranged silver particles communicate with each other to form a silver wire grid electrode. Among them such as Figure 4 and Figure 6 shown. It includes four main steps: the ...

Embodiment 2

[0061] What this embodiment provides is based on the photolithography mask method and the liquid phase method to prepare the preparation method of solar cell micron silver wire grid electrode on the textured single crystal silicon substrate surface, such as figure 1 As shown, among them (1) making a photoresist template; (2) a chemical reaction occurs between the silicon substrate and the mixed solution of silver nitrate and hydrofluoric acid; (3) producing silver particles on the exposed silicon substrate between the photoresists (4) Use a film remover to remove the photoresist on the surface of the silicon substrate; (5) Leave a grid line formed by closely arranged silver particles on the surface of the silicon substrate; (6) High temperature annealing deal with. (7) The tightly arranged silver particles communicate with each other to form a grid electrode of micron silver wires. It includes four main steps: the first is to make a photoresist template, the second is to depo...

Embodiment 3

[0076] What this embodiment provides is based on photolithographic mask method and liquid phase method to prepare the preparation method of silver line grid electrode on the surface of textured polysilicon substrate, such as figure 1 As shown, among them (1) making a photoresist template; (2) a chemical reaction occurs between the silicon substrate and the mixed solution of silver nitrate and hydrofluoric acid; (3) producing silver particles on the exposed silicon substrate between the photoresists (4) Use a film remover to remove the photoresist on the surface of the silicon substrate; (5) Leave a grid line formed by closely arranged silver particles on the surface of the silicon substrate; (6) High temperature annealing Sintering treatment. (7) The tightly arranged silver particles communicate with each other to form a grid electrode of micron silver wires. It includes four main steps: the first is to make a photoresist template, the second is to deposit silver particles on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com