High-refractive-index nano inorganic matter hybrid photovoltaic packaging material

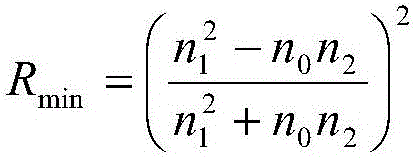

A nano-inorganic, high refractive index technology, used in photovoltaic power generation, non-polymer adhesive additives, polyurea/polyurethane adhesives, etc. and other problems, to achieve the effect of improving refractive index, perfect matching of refractive index and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In terms of parts by mass, to 100 parts of ethylene-vinyl acetate copolymer (the mass content of vinyl acetate VA is 31%), add the 5 parts of nano-hafnium dioxide coated with silane and 5 parts of nano-zinc sulfide coated with 4-nitrothiophenol, 0.3 parts of cross-linking agent tert-butyl peroxyisopropyl carbonate and 0.3 parts of cross-linking agent 1 - Bis(tert-butylperoxide)-3,3,5-trimethylcyclohexane, 0.01 part of UV absorber 2-hydroxy-4-n-octyloxybenzophenone, 0.1 part of light stabilizer decane Diacid bis-2,2,6,6-tetramethylpiperidinol ester, after mixing evenly, extrude and granulate with a twin-screw extruder. Extrude the prepared particles with a single-screw extruder, and the extruded product is cast into a film, and then wound up after cooling to obtain a film with a thickness of 0.5 mm, which is designated as S1.

Embodiment 2

[0022] In terms of parts by mass, to 105 parts of ethylene octene copolymer, add 10 parts of nano-lead telluride with particle size less than 25nm, add 0.1 part of crosslinking agent 2,5-dimethyl-2,5-bis( tert-butyl peroxy) hexane, 2 parts of UV absorber 2,2-tetramethylenebis(3,1-benzoxazin-4-one), 0.5 part of light stabilizer 3,5-di-tert Butyl-4-hydroxy-hexadecyl benzoate, after mixing evenly, extrude and granulate with a twin-screw extruder. Extrude the prepared particles with a single-screw extruder, cast the extruded product into a film, and wind it up after cooling to obtain a film with a thickness of 0.5 mm, which is designated as S2.

Embodiment 3

[0024] In terms of parts by mass, to 120 parts of ethylene-methyl methacrylate copolymer, add 5 parts of nano-gallium phosphide with a particle size smaller than 25nm, and add 5 parts of crosslinking agent 3,3,5 trimethyl peroxide tert-butyl hexanoate, 0.5 parts UV absorber 2-hydroxy-4-n-octyloxybenzophenone, 5 parts light stabilizer bis-1-decyloxy-2,2,6,6-tetra Methylpiperidin-4-ol sebacate, mixed evenly, extruded and granulated by twin-screw extruder. Extrude the prepared particles with a single-screw extruder, cast the extruded product into a film, and wind it up after cooling to obtain a film with a thickness of 0.5 mm, which is designated as S3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com