Preparation method of selective emitter solar cell

A technology of solar cells and emitters, applied in circuits, electrical components, climate sustainability, etc., can solve the problems of high cost, internal damage of silicon wafers, large energy consumption, complex process steps, etc., achieve low cost and reduce high temperature Diffusion process, the effect of simplifying the process path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

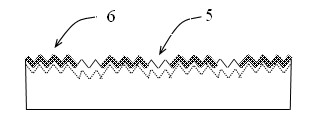

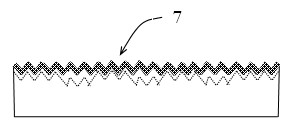

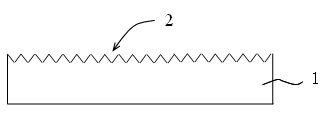

[0034] figure 1 Schematic diagram of the structure of the first screen printing plate used in the present invention; Figure 2a ~ Figure 2g Process flow chart for the preparation of solar cells of the present invention.

[0035] Concrete technological process of the present invention is as follows:

[0036] a. Surface texturing

[0037] See Figure 2a , pre-cleaning the incoming single-crystal silicon wafer 1, the pre-cleaning adopts ultrasonic waves, and adds a certain amount of cleaning and decontaminating agent. Afterwards, the silicon wafer is placed in a sodium hydroxide solution with a temperature of 75-80 °C and a mass percentage concentration of 1%-2% for surface texturing, and an appropriate amount of texturing catalyst is added to achieve a texture in the (100) crystal direction. A uniform "pyramid" textured structure 2 with a size of 1-3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com