Preparation method of solar cell

A technology for solar cells and electrodes, applied in circuits, electrical components, and final product manufacturing, etc., can solve the problems of large leakage current, difficult to control the uniformity of corrosion tank parameters, and large damage to devices, and achieves improved parallel resistance and open circuit voltage. The effect of overcoming plasma bombardment damage and high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

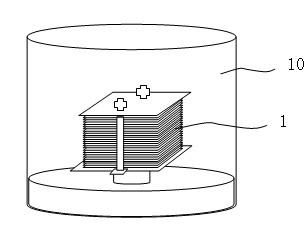

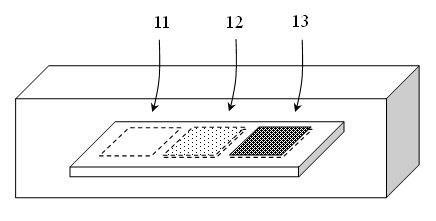

[0038] Figure 1a Structural schematic diagram of the tubular machine used in the present invention; Figure 2a ~ Figure 2f Process flow chart for the preparation of solar cells of the present invention.

[0039] See Figure 1a In this embodiment, the tubular static PECVD method is used to form the masking film, and the single crystal silicon layer 1 is placed in the plasma deposition chamber 10 to deposit the masking film. The specific process is as follows:

[0040] a. Surface texturing

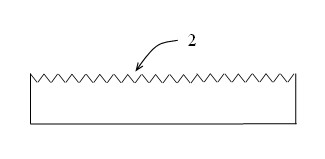

[0041] See Figure 2a , pre-cleaning the incoming single-crystal bare silicon wafer 12, the pre-cleaning adopts ultrasonic waves, and adds a certain amount of cleaning and decontaminating agent. Afterwards, the silicon wafer is placed in a sodium hydroxide solution with a temperature of 75-80°C and a mass percentage concentration of 1%-2% for surface texturing, and an appropriate amount of texturing catalyst is added to make the silicon wafer with a 100-crystal orientation A uniform "py...

Embodiment 2

[0054] Figure 1b It is a structural schematic diagram of the plate machine used in the present invention. In this embodiment, the masking film is produced by a plate-type PECVD static method. The specific process is as follows:

[0055] a. Surface texturing

[0056] See Figure 2a , pre-cleaning the incoming single-crystal bare silicon wafer 12, the pre-cleaning adopts ultrasonic waves, and adds a certain amount of cleaning and decontaminating agent. Afterwards, the bare silicon wafer 12 is placed in a sodium hydroxide solution with a temperature of 75-80°C and a mass percent concentration of 1%-2% for surface texturing, and an appropriate amount of texturing catalyst is added to achieve a texture in the 100-crystal orientation. A uniform "pyramid" textured structure 2 with a size of 1-3um is formed on the surface of the silicon wafer, so that the surface has a good light-trapping effect.

[0057] b. Fabrication of Diffusion Masking Film

[0058] see next Figure 2b Pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com