Patents

Literature

48results about How to "Increase parallel resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lead-free silver conductive paste used for positive electrode of solar battery and preparation technique thereof

InactiveCN101609850AStrong adhesionLower resistanceFinal product manufactureConductive materialConductive pasteSilver electrode

The invention provides a lead-free silver conductive paste used for positive electrode of solar battery and a preparation technique thereof. The paste comprises the following materials by weight percentage: 65 to 85 percent of silver powder, 2 to 8 percent of lead-free glass powder, 10 to 25 percent of organic carrier and 0.1 to 3 percent of additive. The paste adopts the lead-free glass powder of Si-B-Bi-Al-Ti-Zn-O series to replace the traditional lead-bearing glass powder; and the series glass powder has lower softening point, can lead the silver electrode to have good adhesive force after sintering, and ensures the silver electrode to be well contacted with a silicon substrate. In addition, zinc resinate is used as the additive in the invention, not only can well improve the printing performance of the paste, but also can improve the electrical property of the electrode.

Owner:CENT SOUTH UNIV

Method for manufacturing silicon solar cell

InactiveCN101783374ALow sheet resistanceLower ohmic contactFinal product manufactureSemiconductor devicesMetallic electrodeOhmic contact

The invention discloses a method for manufacturing a silicon solar cell. In the process of manufacturing a PN junction on a silicon wafer, a selective diffusion technology method is adopted, i,e. laser is utilized to heat a position, on which a positive electrode intends to be manufactured, on the surface of the silicon wafer; and under the action of heating, phosphorus in a phosphorus source uniformly adhered on the surface diffuses towards the inner of the silicon wafer, thus a heavy doping zone with smaller sheet resistance is formed at the position on which the positive electrode intends to be manufactured to effectively reduce the sheet resistance of the silicon solar cell, thereby not only being beneficial for increasing the open-circuit voltage of the silicon solar cell; the increase of the open-circuit voltage effectively improves the conversion efficiency of the silicon solar cell, reduces ohmic contact of a metal electrode and the silicon solar cell, thereby reducing the series resistance of the silicon solar cell, and being capable of meeting the purpose of industrialized production better.

Owner:SUN EARTH SOLAR POWER

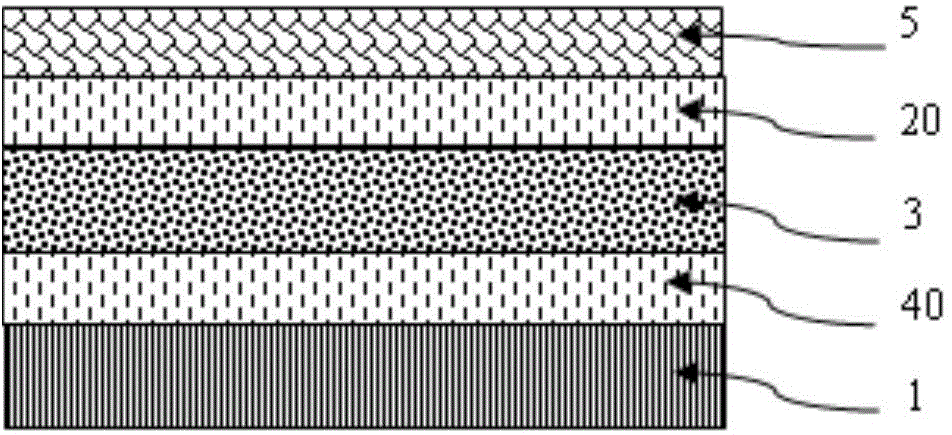

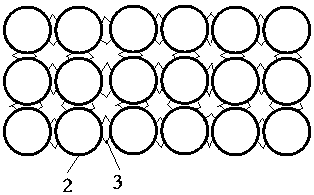

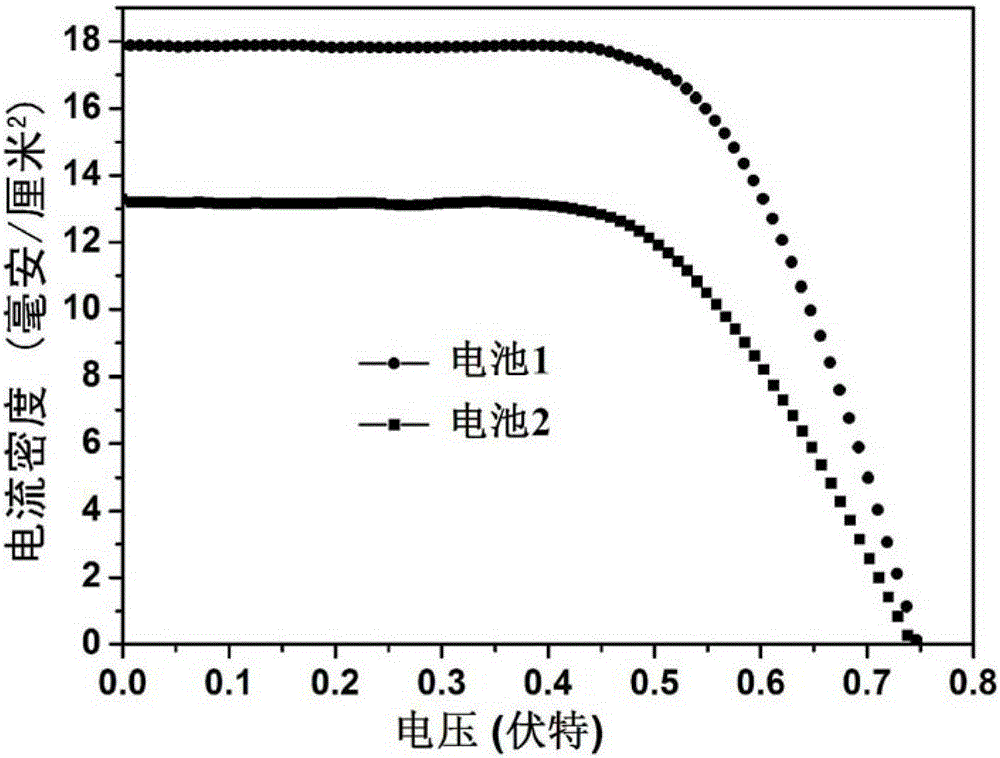

Polymer solar battery with inverted structure and manufacturing method thereof

InactiveCN103956430AAccelerate the process of industrializationEfficient collectionSolid-state devicesSemiconductor/solid-state device manufacturingSolar batteryElectron

The invention provides a polymer solar battery with an inverted structure. According to the polymer solar battery, an laminated structure is composed of a glass substrate, an indium tin oxide (ITO) transparent conducting film, an electron transporting layer, an interface modification layer, an organic active layer and an MoO3 / Ag composite electrode in sequence, wherein the electron transporting layer is a zinc aluminum oxide (ZAO) thin film, the interface modification layer is a polyvinylpyrrolidone thin film, and the organic active layer is a poly-3-hexyl thiophene-fullerene derivative thin film. The polymer solar battery with the inverted structure has the advantages that polyvinylpyrrolidone is used as the interface modification layer, so that materials of the organic active layer make tight contact with materials of the inorganic electron transporting layer, the series resistance of a device can be effectively reduced, the parallel resistance of the device can be effectively increased, charge carriers are effectively collected, carrier recombination is reduced, the number of fill factors of the battery is obviously increased, and energy conversion efficiency of the battery is obviously improved; on the premise of not increasing cost, large-area commercial production can be facilitated, the industrialization process of the polymer solar battery is accelerated, and social demands are met.

Owner:NANKAI UNIV

Method for rapidly sintering solar wafer

InactiveCN102332491AImprove Ag electrode contact resistanceQuality improvementFinal product manufactureSemiconductor devicesBack surface fieldContact resistance

The invention provides a sintering method, and in particular relates to a method for rapidly sintering a solar wafer. A rapid thermal processing way is adopted to sinter large-area cells of silk-screen printing. The method comprises the following steps of: conveying, drying and exhausting cokes, rapidly heating to sinter as well as sintering at a high temperature and cooling. The method has the beneficial effects that the passivation effect is good, the minority carrier lifetime is improved greatly, the contact resistance of a Ag (silver) electrode and the quality of Al-BSFs (aluminum back surface fields) for the cells can be improved, the thermal stress is reduced, the contact resistances of solar cells are reduced obviously so as to improve the utilization of short wave spectra, the evenly good Al-BSFs are formed to improve the open-circuit voltages and filling factors of the cells, the warping of the cells is reduced, and the conversion efficiency and finished product ratio of the cells can be improved.

Owner:浙江天明国际科技有限公司

Alloy electrode capable of improving efficiency and stability of solar cell

InactiveCN104465804AInhibition of the vulnerability to spreadIncrease parallel resistancePhotovoltaic energy generationSemiconductor devicesAluminiumContact barrier

The invention belongs to the field of photoelectric devices, and discloses an alloy electrode capable of improving the efficiency and the stability of a solar cell. The alloy electrode is a binary or complex alloy electrode formed in the mode that precious metal silver is combined with metal such as aluminum, titanium, zinc, copper and / or magnesium. The invention further discloses the solar cell with the alloy electrode serving as the cathode or the anode of the cell. By means of the alloy electrode and the solar cell, matching between the energy level of the alloy electrode and the energy level of a carrier transport layer is easily improved, the contact barrier is reduced, and the efficiency of the cell is improved; silver atoms in the alloy electrode are slowly diffused to the carrier transport layer and an optical active layer, and therefore the stability of the cell can be improved; the use amount of silver materials in a unit area of the cell is decreased, the cost of the cell is easily controlled, and resources are saved.

Owner:上海纳晶科技有限公司

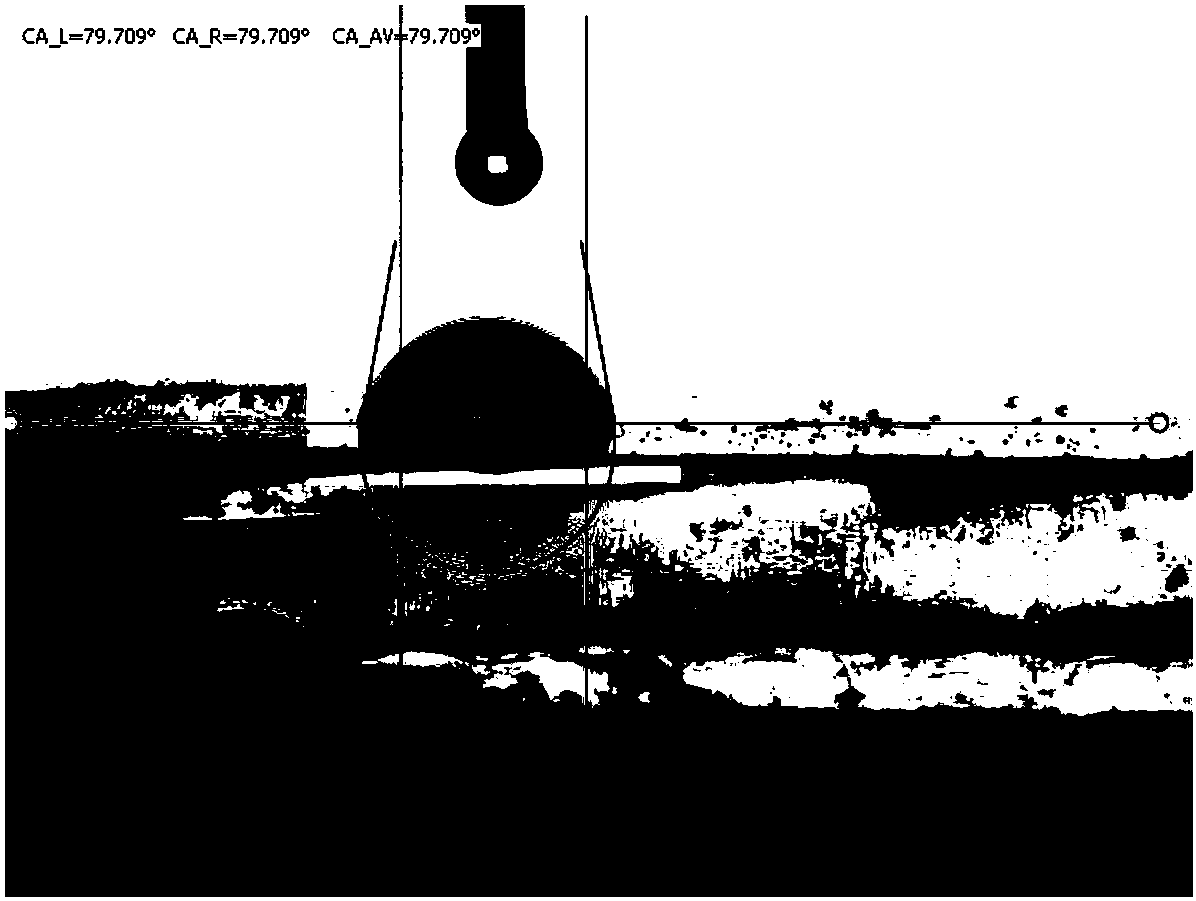

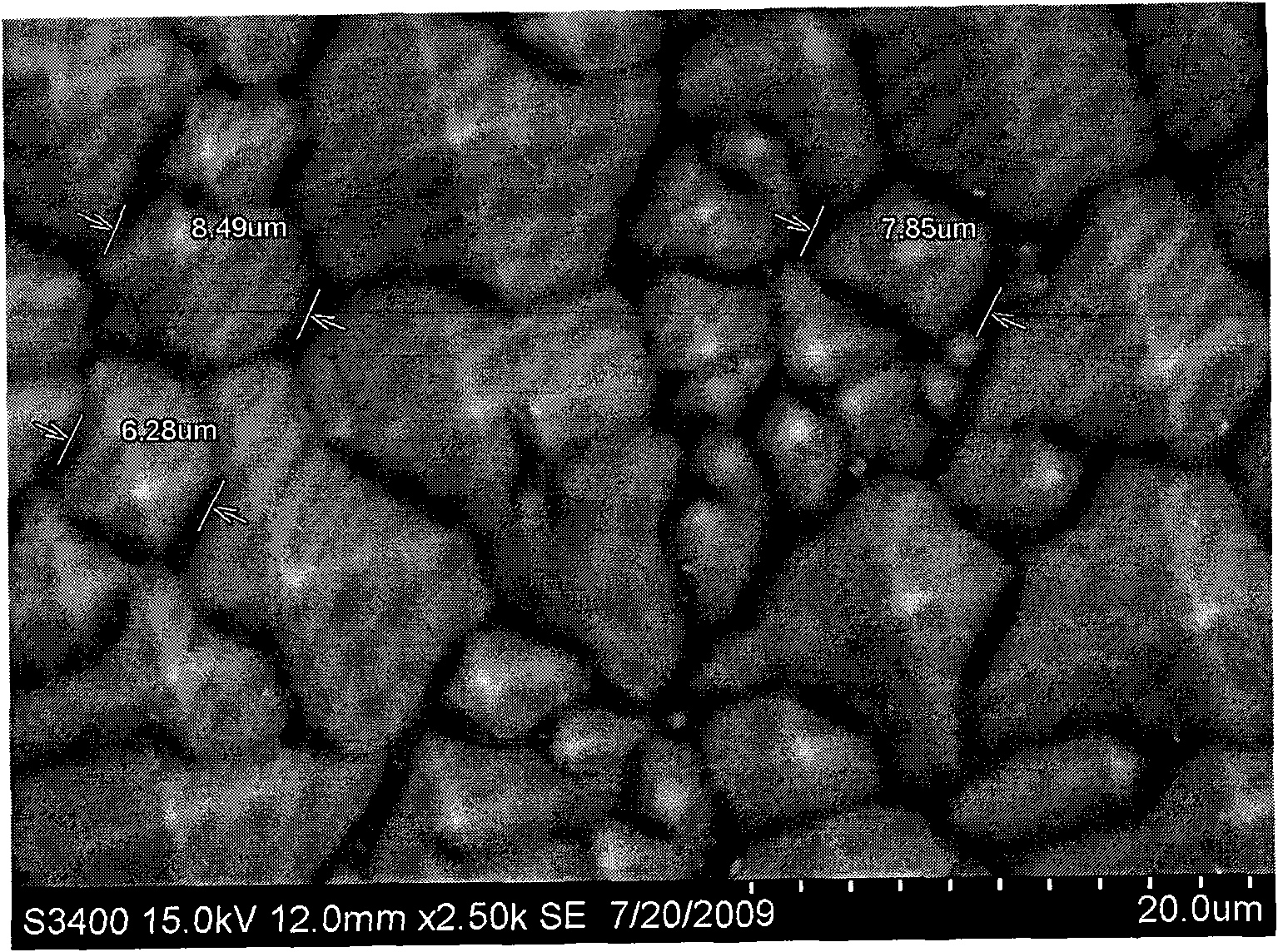

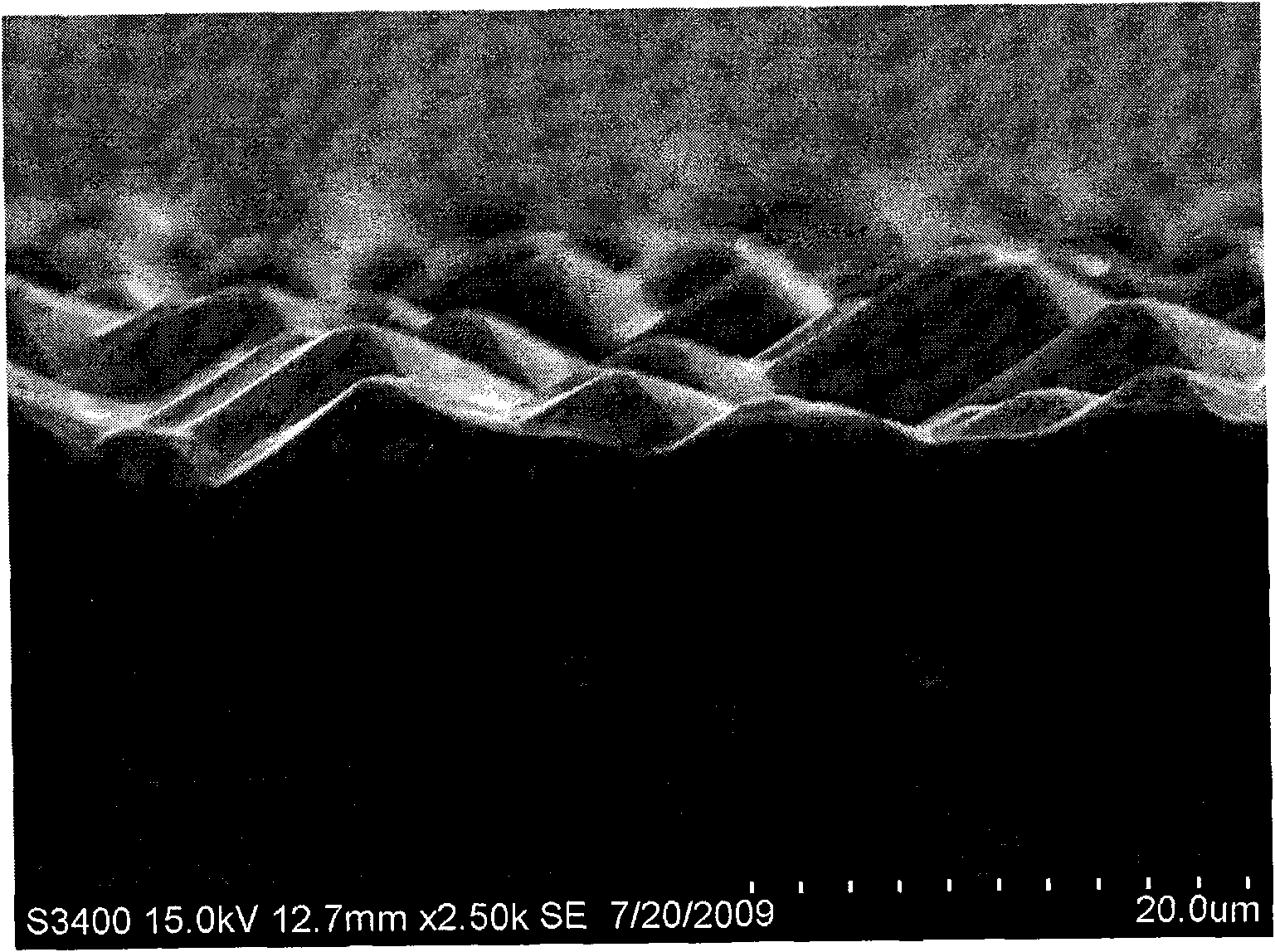

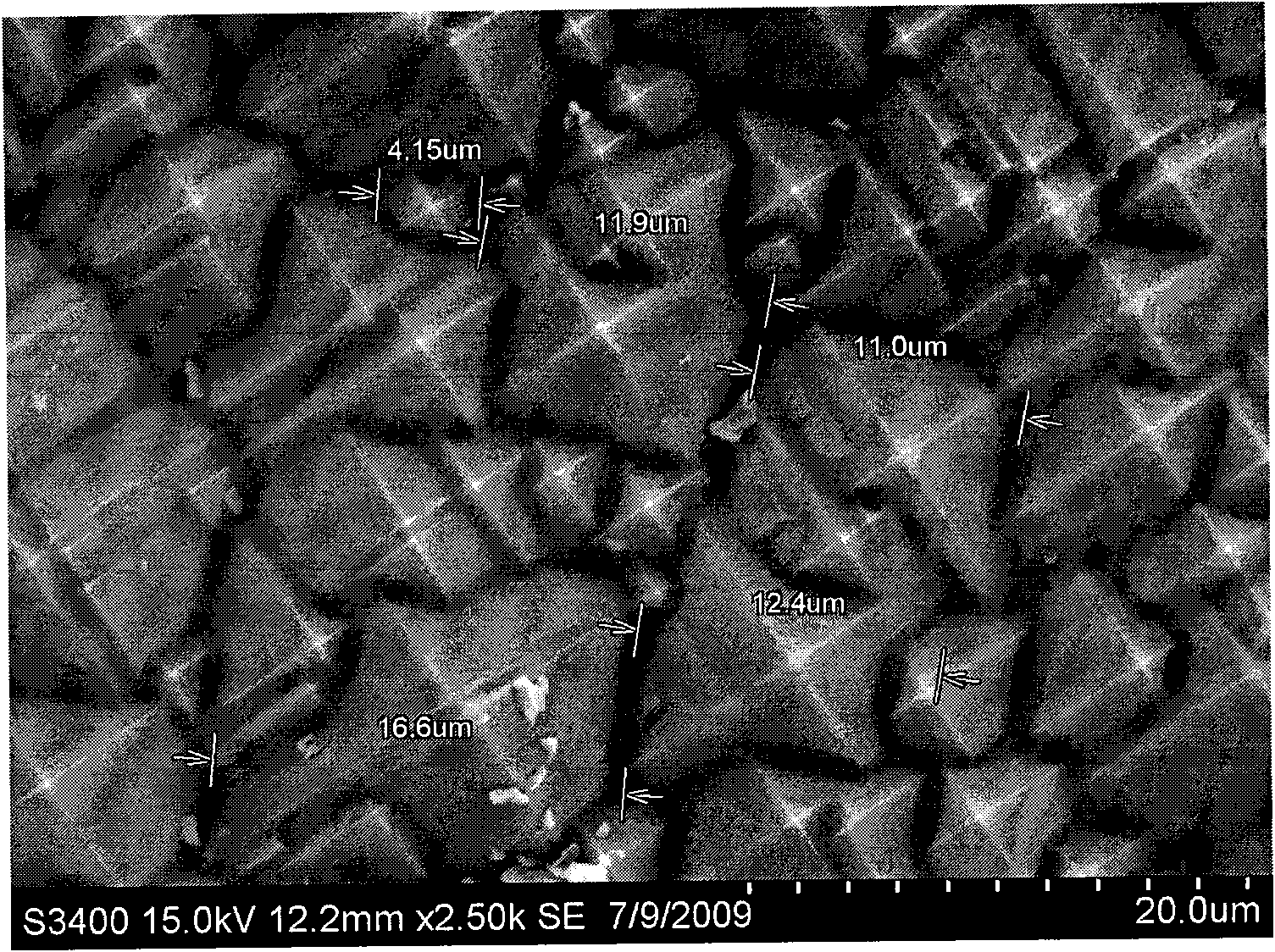

Polycrystalline velvet additive-matched surface treatment technology after felting

InactiveCN103696021APrevent looseningImprove uniformityAfter-treatment detailsFinal product manufactureHigh concentrationScreen printing

The invention discloses a polycrystalline velvet additive-matched surface treatment technology after felting. The technology comprises the following steps: (a) putting a silicon slice into a system to which a novel polycrystalline velvet additive is added to felt, so as to form a small suede with a better anti-reflection effect; (b) heating a KOH solution to an alkaline bath by using a heat exchanger with large powder, and then spraying the felted silicon slice up and down by using a hot alkaline liquor; (c) cleaning the surface of the silicon slice by using specific concentration of HF / HCL mixed acid. By adopting the technology disclosed by the invention, excessive nanoscale porous silicon can be removed, recombination is effectively reduced, open pressure and parallel resistance are improved, leakage current is reduced, and an aluminum back field also can be effectively prevented from loosening and falling off after a silk screen is printed and sintered. The capillarity on the suede is relieved due to higher concentration of hot alkaline washing, a pile pit is better in homogeneity, the probability of over-etching and P aberration of a pipe is finally reduced, and impurities in the pile pit of the small suede are removed by higher concentration of mixed acid washing. Thus, recombination is greatly reduced.

Owner:TAITONG TAIZHOU IND

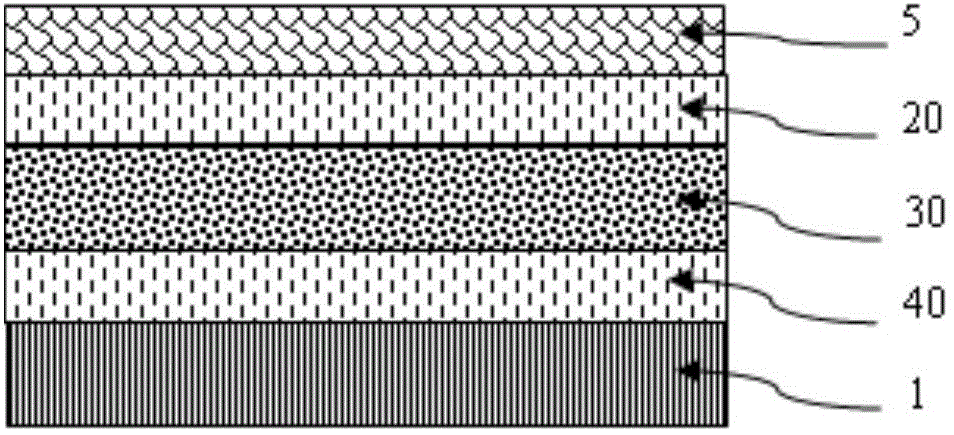

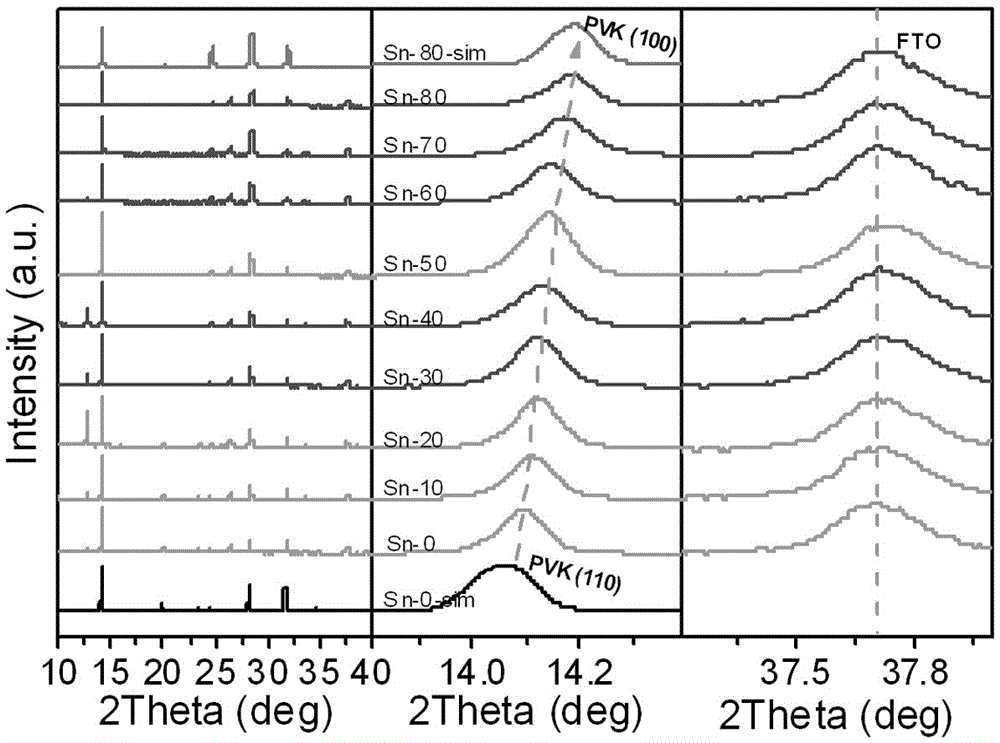

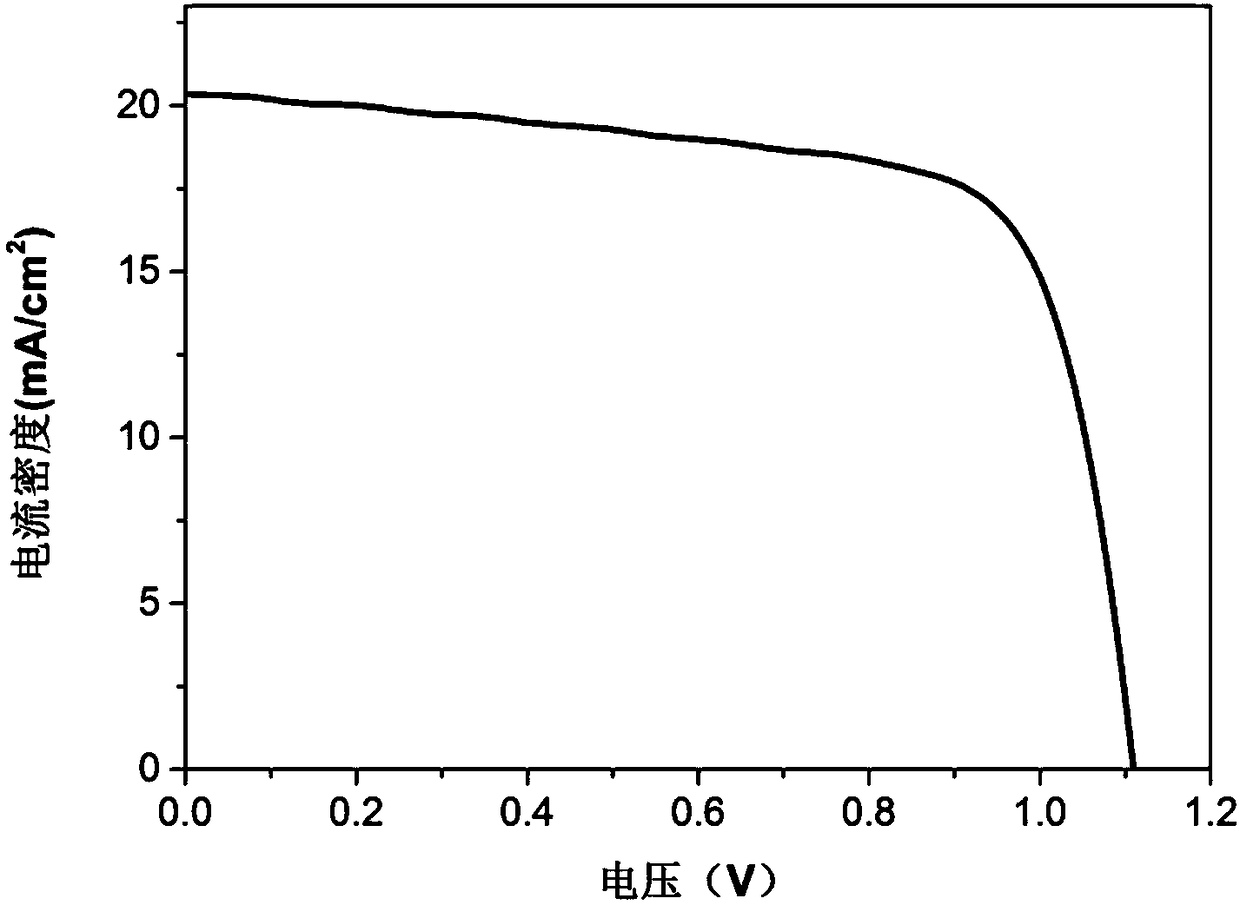

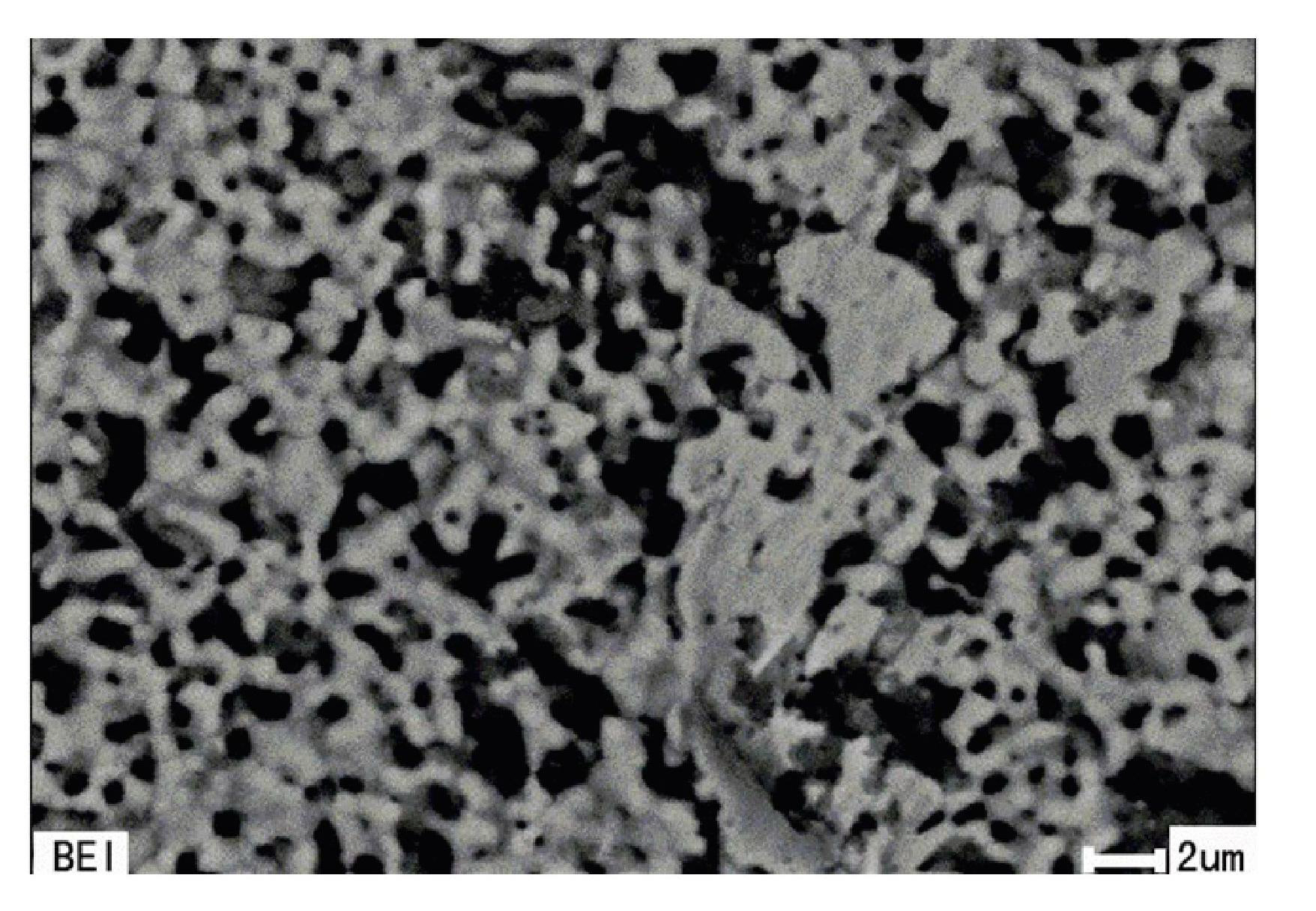

Lead-tin hybrid perovskite thin film, and preparation method and application therefor

ActiveCN105810831AIncrease coverageQuality improvementSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellSolvent

The invention provides a lead-tin hybrid perovskite thin film, and a preparation method and an application therefor. The preparation method for the lead-tin hybrid perovskite thin film comprises the specific steps of dissolving PbRE<2> and SnRE<2> into DMF and DMSO mixed solvent to form a PbRE<2> solution and an SnRE<2> solution respectively, wherein RE is CL, Br or I; measuring the PbRE<2> solution and the SnRE<2> solution, and enabling the two kinds of solutions to be mixed to form a precursor liquid; coating a substrate with the precursor liquid in a spin-coating manner; then coating the substrate with a CH<3>NH<3>RE isopropanol solution in a spin-coating manner; and carrying out annealing on the substrate to obtain the hybrid perovskite thin film. According to the lead-tin hybrid perovskite thin film, the lead-tin hybrid perovskite thin film is prepared by a liquid phase two-step method, so that the content of heavy metal-lead in the thin film can be effectively reduced; and in addition, the coverage degree and the mass of the thin film can be improved, the pin holes of the thin film can be reduced, the electric leakage path can be reduced, and the photoelectric conversion efficiency of the prepared lead-tin hybrid perovskite solar cell can be improved.

Owner:HEBEI UNIVERSITY

Method for etching edges of solar battery

InactiveCN102437240ANot subject to vapor phase corrosionImprove stabilityFinal product manufactureSemiconductor devicesSolar batteryDrain current

The invention provides a method for etching edges of a solar battery, which is characterized by comprising the following steps that: a diffused silicon chip is provided, primary plasma etching is executed on the diffused silicon chip so as to remove phosphorosilicate glass on the periphery of the diffused silicon chip, and then wet etching is performed on the silicon chip after the plasma etching according to a conventional flow. By adding one time of traditional plasma etching, the phosphorosilicate glass on the periphery of the silicon chip after being diffused can be removed, and the major area on the middle part of the silicon chip is still covered by the phosphorosilicate glass, so the hydrophobic property of the exposed silicon main body on the periphery of the silicon chip is also utilized to prevent the etching liquid from infiltrating the upper surface of the silicon chip. After twice etching, the parallel-connection resistance and the filler factor of cell slice can be remarkably improved, and the drain current can be remarkably reduced. Therefore, the wet etching with low cost, high stability and high parallel-connection resistance can be realized.

Owner:百力达太阳能股份有限公司

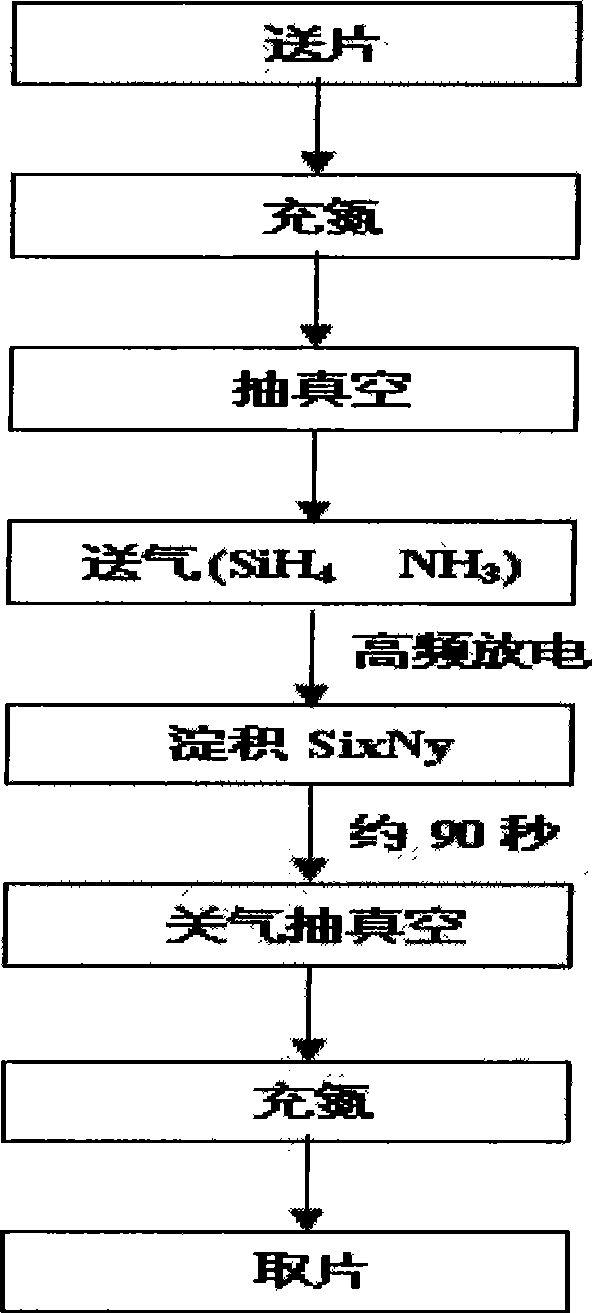

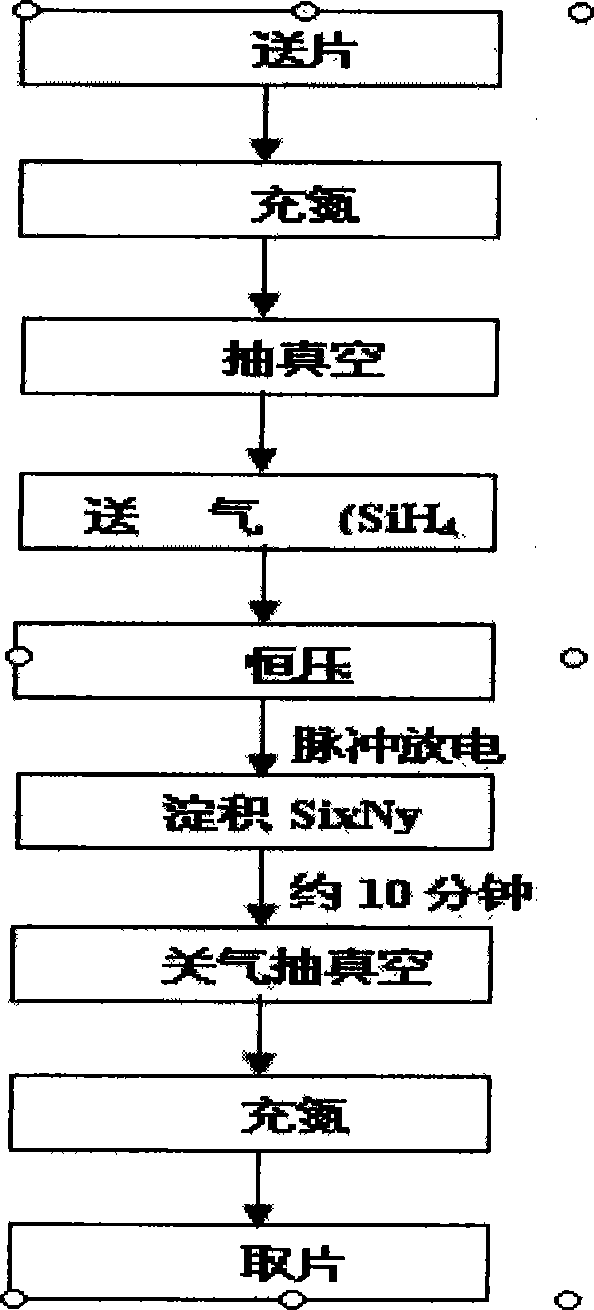

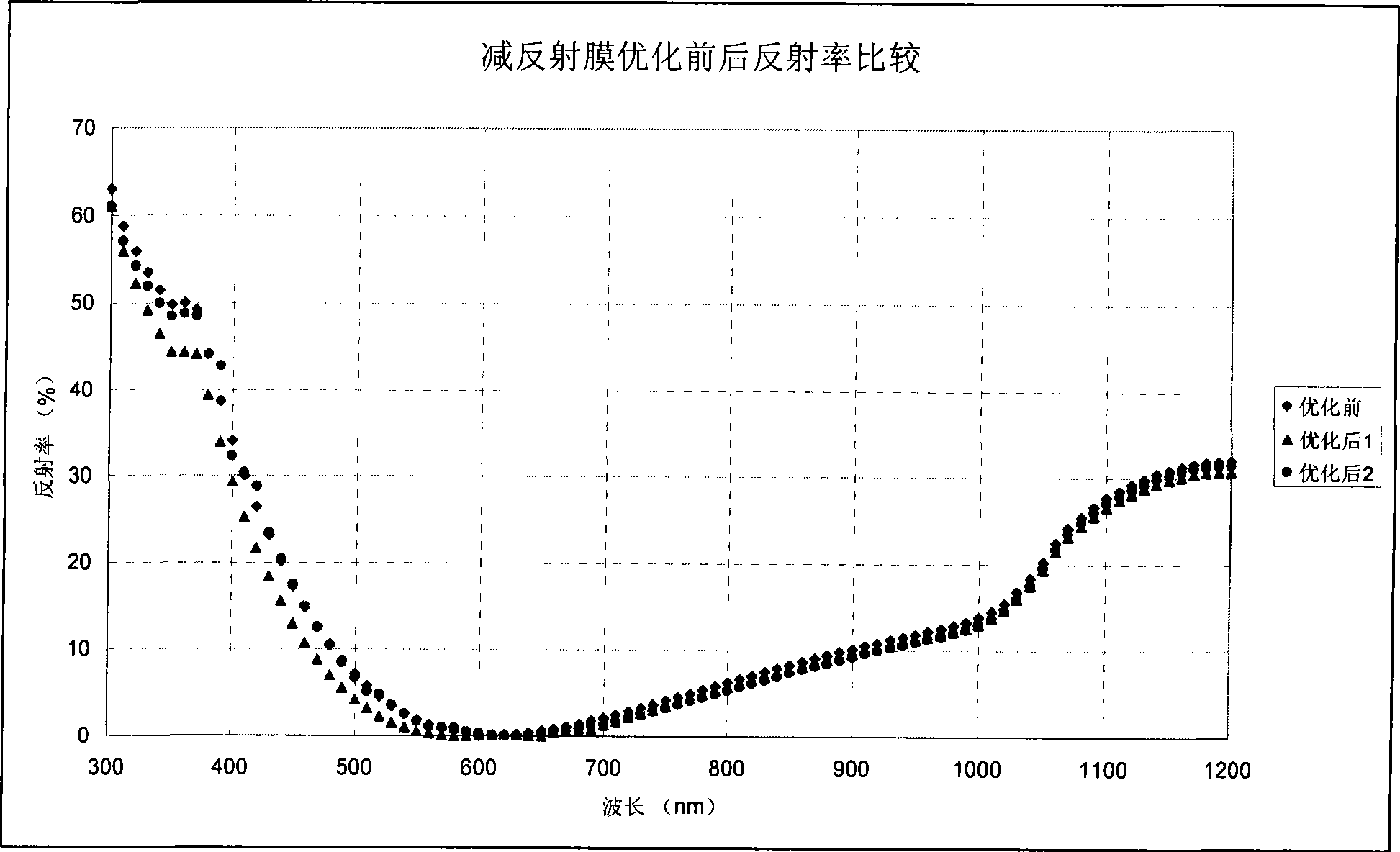

Production technology for anti-reflection film of solar cell

InactiveCN101431122AReduce Radiation DamageSlow growth rateFinal product manufactureSemiconductor devicesReflection lossSilanes

The invention discloses an improved SixNy antireflection coating growth technique which can effectively reduce the reflection loss of surface incident light, simultaneously enhance the compactness of a surface antireflection coating and enhance the blocking effect on harmful impurities, such as Na<+>, Fe<+>, etc. The power of a medium-high frequency plasma source in the growth technique process is 800W, the environmental temperature in a reaction chamber is 480 DEG C, the flow rate of silane is 300sccm, the flow rate of ammonia maintains the technological process parameter of 1,800sccm, and the advance and retreat speed of a carrying boat of a technological silicon wafer is 600mm / min, thereby ensuring the grown coating to be capable of carrying out the timely passivation and annealing (carrying out the passivation and the annealing during the growth), therefore, the compactness thereof is enhanced and the surface radiation damage to PN junction can be repaired timely and effectively. The growth technique is applicable to the production of crystalline silicon solar cells.

Owner:浙江弘晨光伏能源有限公司

Inverted gradient bulk heterojunction perovskite solar cell on basis of gallium oxide protective layer and method for preparing inverted gradient bulk heterojunction perovskite solar cell

ActiveCN108281560AImprove photoelectric conversion efficiencyImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingLow temperature depositionHeterojunction

The invention relates to an inverted gradient bulk heterojunction perovskite solar cell on the basis of a gallium oxide protective layer and a method for preparing the inverted gradient bulk heterojunction perovskite solar cell. The inverted gradient bulk heterojunction perovskite solar cell which is a perovskite cell comprises a transparent conductive substrate, a hole transport layer, a perovskite light absorption layer, an electron transport layer and metal electrodes. The inverted gradient bulk heterojunction perovskite solar cell and the method have the advantages that a high-quality gallium oxide thin film is prepared by the aid of low-temperature deposition atomic layer bottom sinking processes with simple technologies and is used as a cushion layer between the electron transport layer and the metal electrodes, and accordingly the photovoltaic performance of devices can be effectively improved; the gallium oxide thin film with inorganic and hydrophobic characteristics can be used as the protective layer, accordingly, cell erosion due to external environments can be effectively isolated, and the stability of the devices can be enhanced; non-fullerene materials IDIC are dissolved in a green and environment-friendly solvent ethyl acetate to prepare gradient heterojunction perovskite thin films, accordingly, defects of perovskite can be effectively passivated, the performance of the devices can be enhanced, and thin film preparation toxic environments can be relieved.

Owner:WUHAN UNIV

Method for preparing single crystal silicon velvet surface

InactiveCN101634046AAvoid damageImprove efficiencyAfter-treatment detailsHydrofluoric acidPhysical chemistry

The invention discloses a method for preparing a single crystal silicon velvet surface, comprising the following steps: corroding a single crystal silicon piece by alkali corrosion solution; and corroding and preparing the single crystal silicon velvet surface by acid corrosion solution. The alkali corrosion solution is mixed solution which comprises sodium hydroxide, sodium silicate, isopropanol and water, wherein the concentration range of the sodium hydroxide is 0.1-0.5 mol / L, the concentration range of the sodium silicate is 0.01-0.07 mol / L, and the concentration range of the isopropanol is 0.7-2.0 mol / L; the acid corrosion solution is mixed solution which comprises hydrofluoric acid, nitric acid and water, the concentration range of the hydrofluoric acid is 1-10 mol / L, and the concentration range of the nitric acid is 3-30 mol / L. The electricity leakage of a single crystal battery is smaller than the electricity leakage of the normal alkali velvet battery, thereby the conversion efficiency of a single crystal silicon solar battery is increased, and the power of the single crystal silicon assemblies is improved.

Owner:HANWHA SOLARONE QIDONG

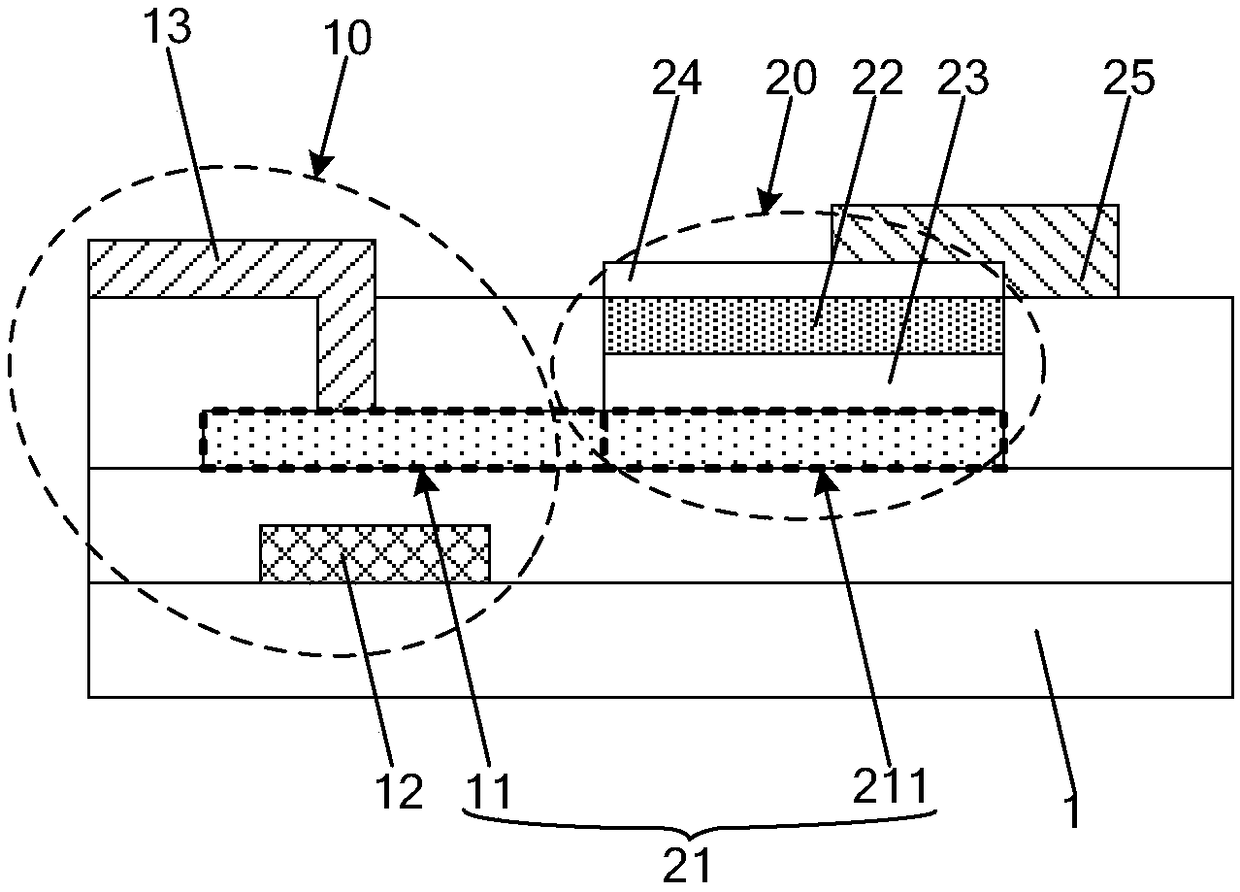

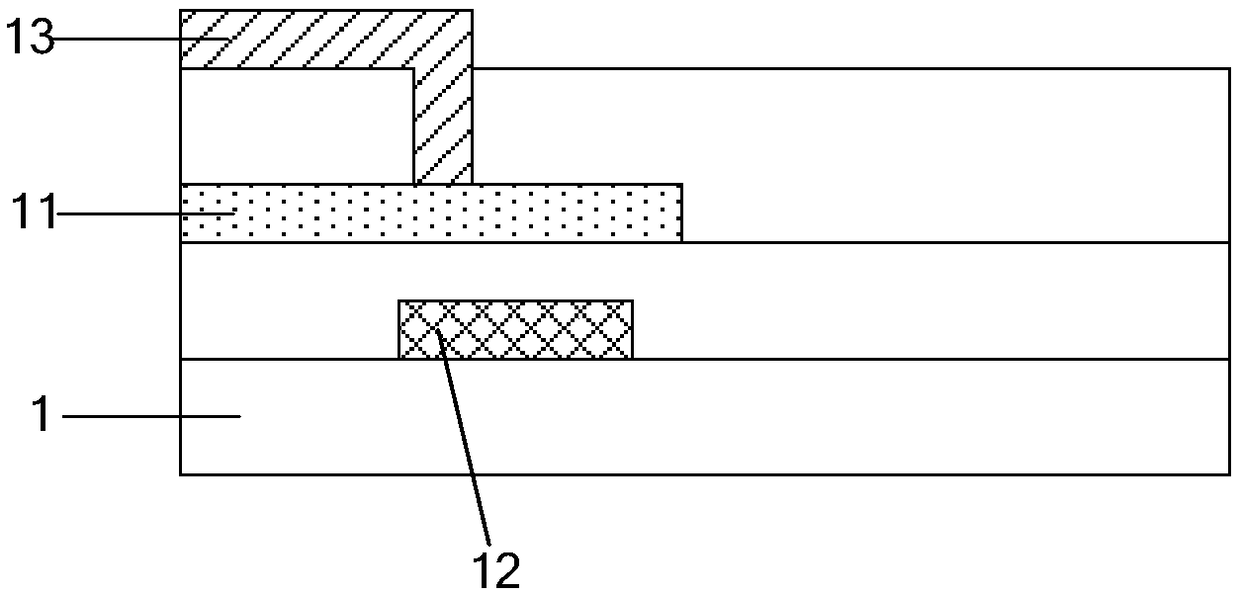

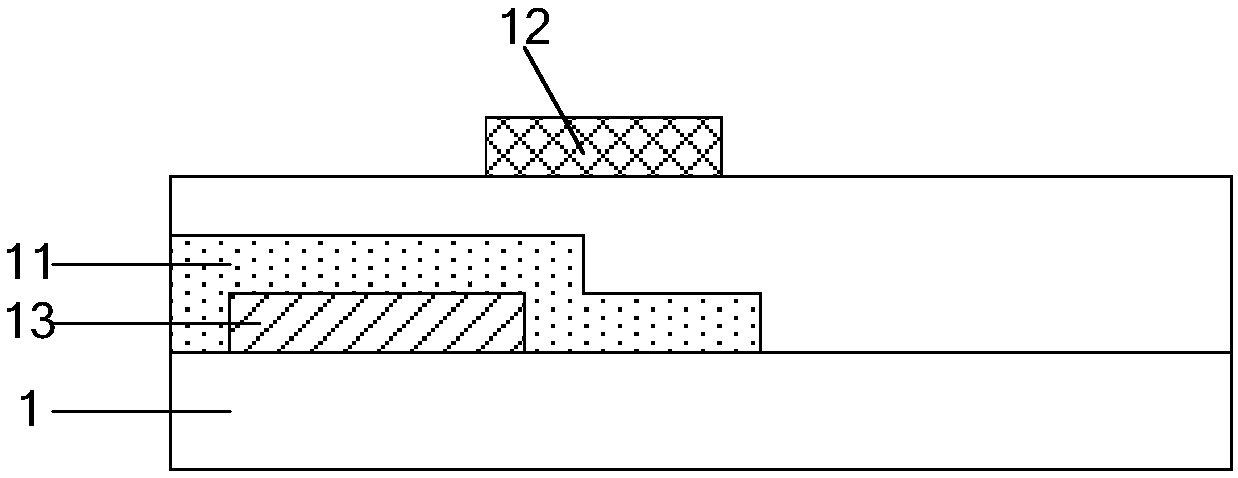

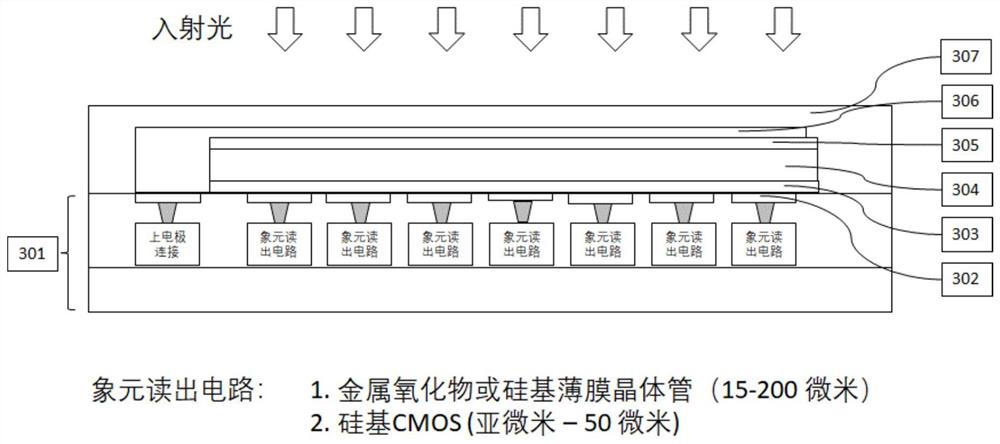

Photosensitive assembly and preparation method thereof, array substrate and display device

InactiveCN108922904AHigh precisionIncrease contrastSolid-state devicesPrint image acquisitionDisplay deviceEngineering

The embodiment of the invention provides a photosensitive assembly and a preparation method thereof, an array substrate and a display device, and relates to the technical field of displaying. A dark current of photodiode can be reduced, and the detection effect of the photodiode can be improved. The photosensitive assembly comprises a switching unit comprising an active layer, and the photodiode;the photodiode comprises a P-type semiconductor layer and an N-type semiconductor layer which are arranged in a stacked mode; the N-type semiconductor layer comprises a direct facing part directly facing the P-type semiconductor layer, and an extension part extending from the direct facing part out of the boundary of the P-type semiconductor layer; and at least part of the extension part is used as the active layer.

Owner:BOE TECH GRP CO LTD

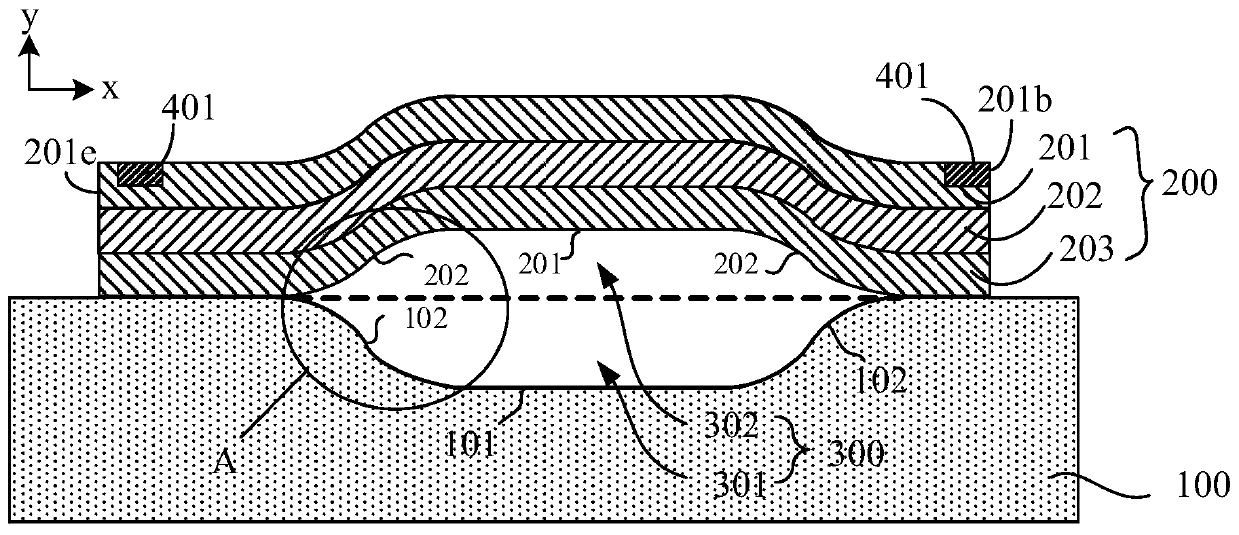

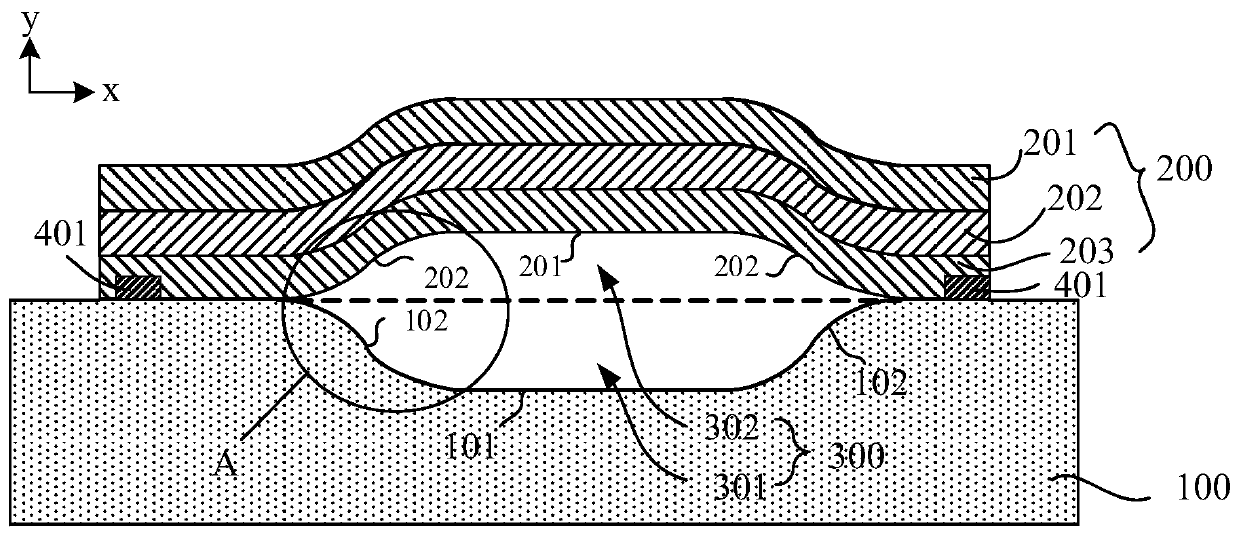

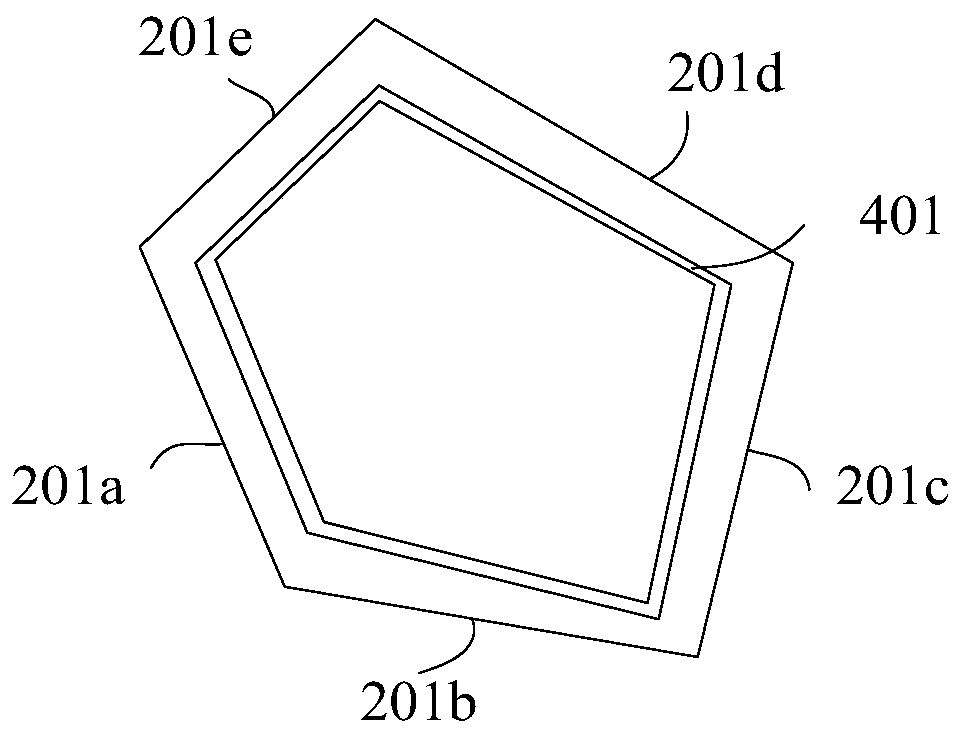

Bulk acoustic wave resonator, manufacturing method thereof and semiconductor device

ActiveCN110868186AImprove the acoustic impedance ratioHigh Q valueImpedence networksHigh level techniquesDevice materialAcoustic wave

The invention relates to the technical field of semiconductors, and discloses a bulk acoustic wave resonator, a manufacturing method thereof and a semiconductor device. The bulk acoustic wave resonator comprises a substrate; and a multi-layer structure which is formed on the substrate, wherein the multi-layer structure sequentially comprises a lower electrode layer, a piezoelectric layer and an upper electrode layer from bottom to top, a cavity is formed between the substrate and the multilayer structure, the lower electrode layer or the upper electrode layer is internally provided with a groove, and the groove is filled with a filling material different from the electrode material of the corresponding electrode layer. According to the resonator, the cavity with the lower half cavity and the upper half cavity is formed, the groove is formed in the lower electrode layer or the upper electrode layer, and the groove is filled with the filling material different from the electrode materialof the corresponding electrode layer, so that a novel bulk acoustic wave resonator structure is formed, and the resonator has relatively good performance.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

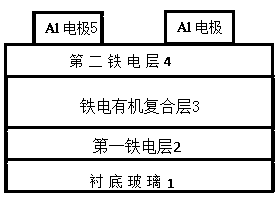

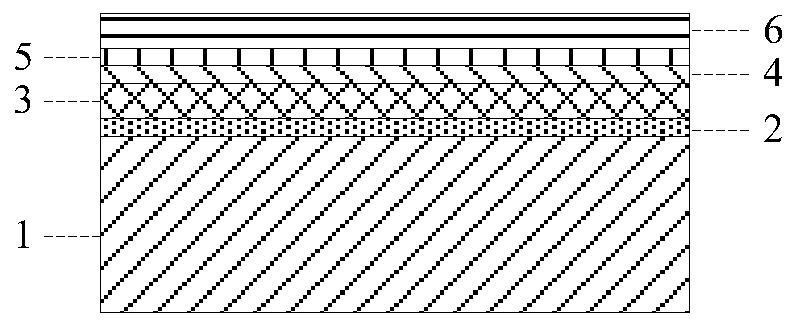

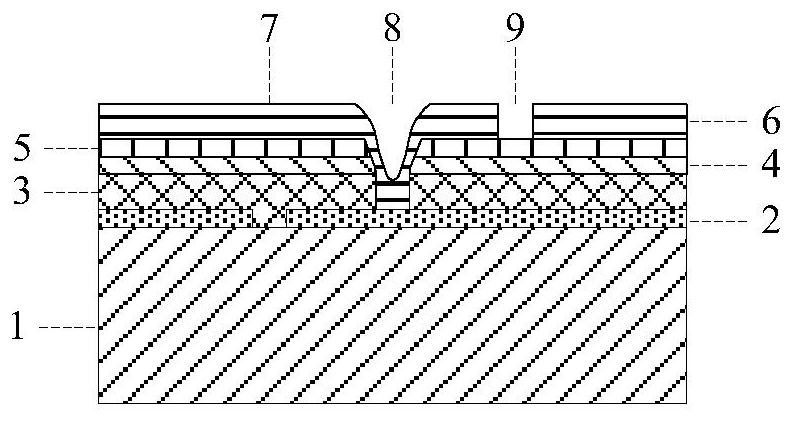

Compositely laminated ferroelectric-organic hybrid solar cell, and preparation method thereof

PendingCN109449292AIncrease parallel resistanceImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingBarium titanateOrganic polymer

The invention relates to the field of solar cell manufacturing, in particular to a compositely laminated ferroelectric-organic hybrid solar cell, and a preparation method thereof. The solar cell comprises substrate glass, a first ferroelectric layer, a ferroelectric-organic composite layer, a second ferroelectric layer and electrodes which are arranged from bottom to top, wherein the ferroelectric-organic composite layer is a composite layer comprising a ferroelectric layer and an active layer, and comprises a (P3HT:PCBM):BTO sol layer formed by the ferroelectric inorganic nanomaterial bariumtitanate (BTO) and the organic polymer material P3HT:PCBM of the active layer. The solar cell and the preparation method thereof have the advantages that ferroelectric BTO nanoparticles are introduced, and a built-in electric field generated by spontaneous polarization of the particles is utilized to inhibit electron hole recombination and reduce the generation of dark currents, so that the cell efficiency can be improved; as electron hole separation is promoted through the BTO built-in electric field, the parallel resistance of the cell is increased, and a higher fill factor is finally achieved; and polymer / inorganic nano-BTO composite photovoltaic devices can be manufactured on the basis of preparation of inorganic nano-bismuth ferrite ferroelectric materials.

Owner:GUANGDONG UNIV OF TECH

Lead-free silver conductive paste used for positive electrode of solar battery and preparation technique thereof

InactiveCN101609850BStrong adhesionLower resistanceFinal product manufactureConductive materialConductive pasteSilver electrode

The invention provides a lead-free silver conductive paste used for positive electrode of solar battery and a preparation technique thereof. The paste comprises the following materials by weight percentage: 65 to 85 percent of silver powder, 2 to 8 percent of lead-free glass powder, 10 to 25 percent of organic carrier and 0.1 to 3 percent of additive. The paste adopts the lead-free glass powder of Si-B-Bi-Al-Ti-Zn-O series to replace the traditional lead-bearing glass powder; and the series glass powder has lower softening point, can lead the silver electrode to have good adhesive force aftersintering, and ensures the silver electrode to be well contacted with a silicon substrate. In addition, zinc resinate is used as the additive in the invention, not only can well improve the printing performance of the paste, but also can improve the electrical property of the electrode.

Owner:CENT SOUTH UNIV

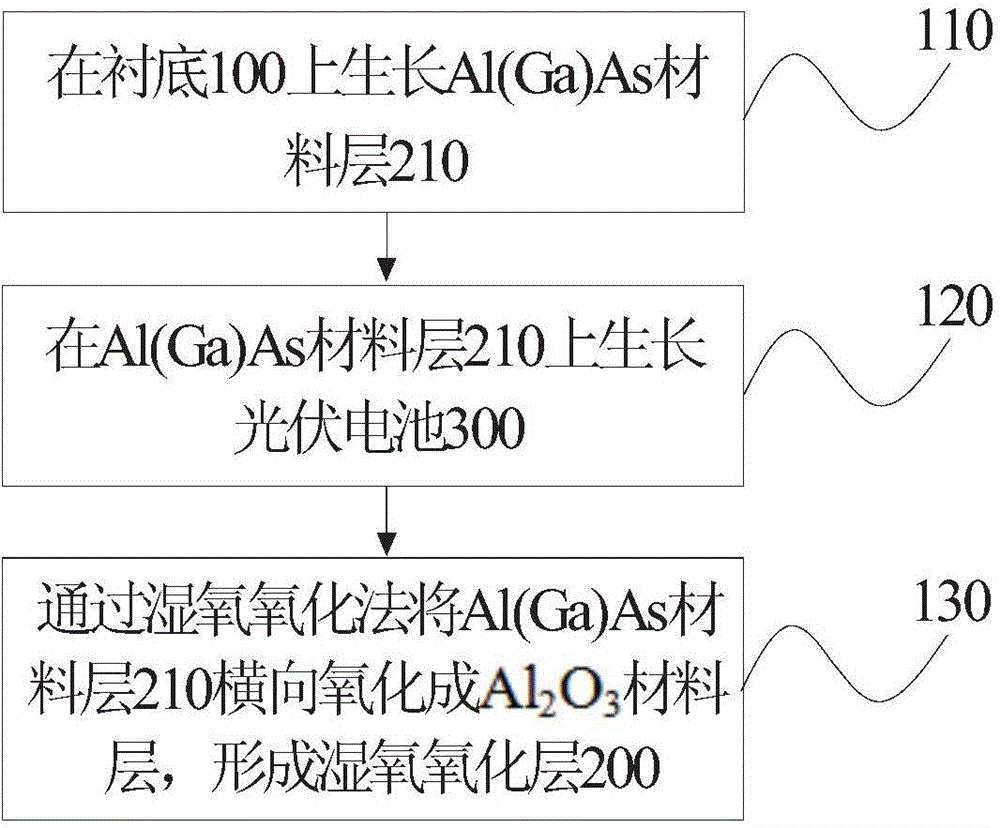

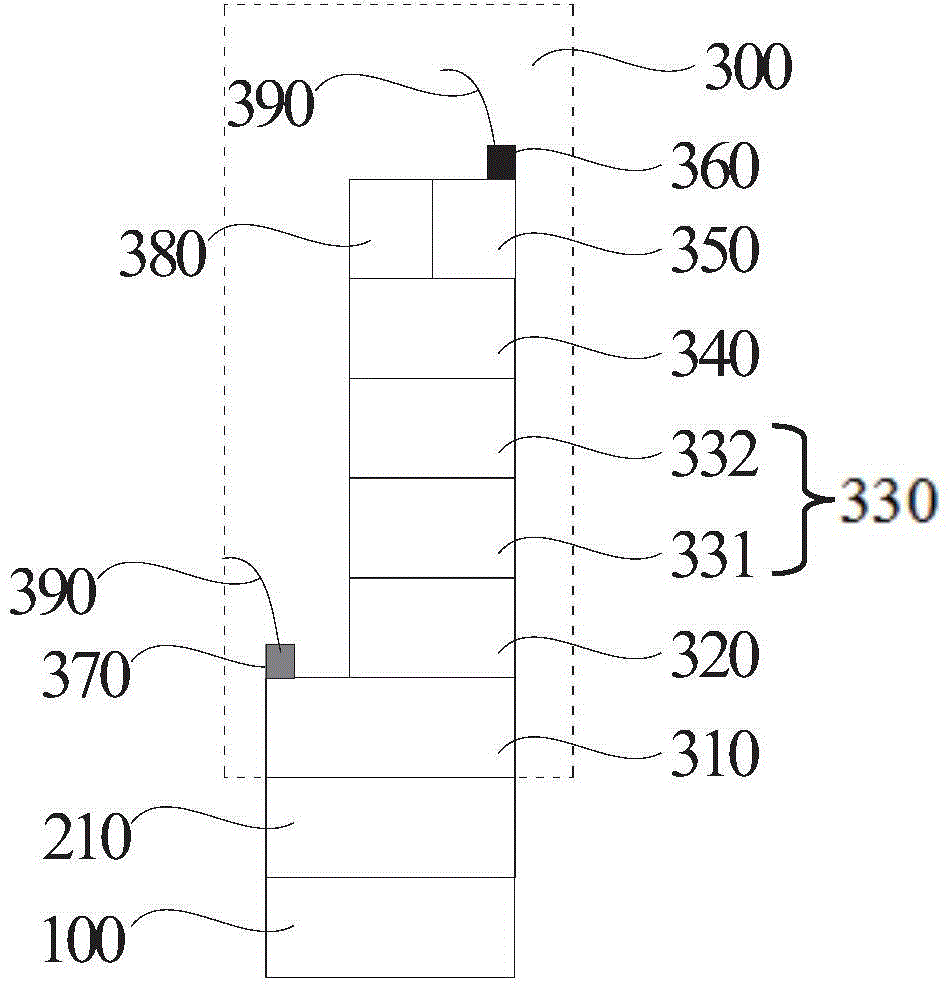

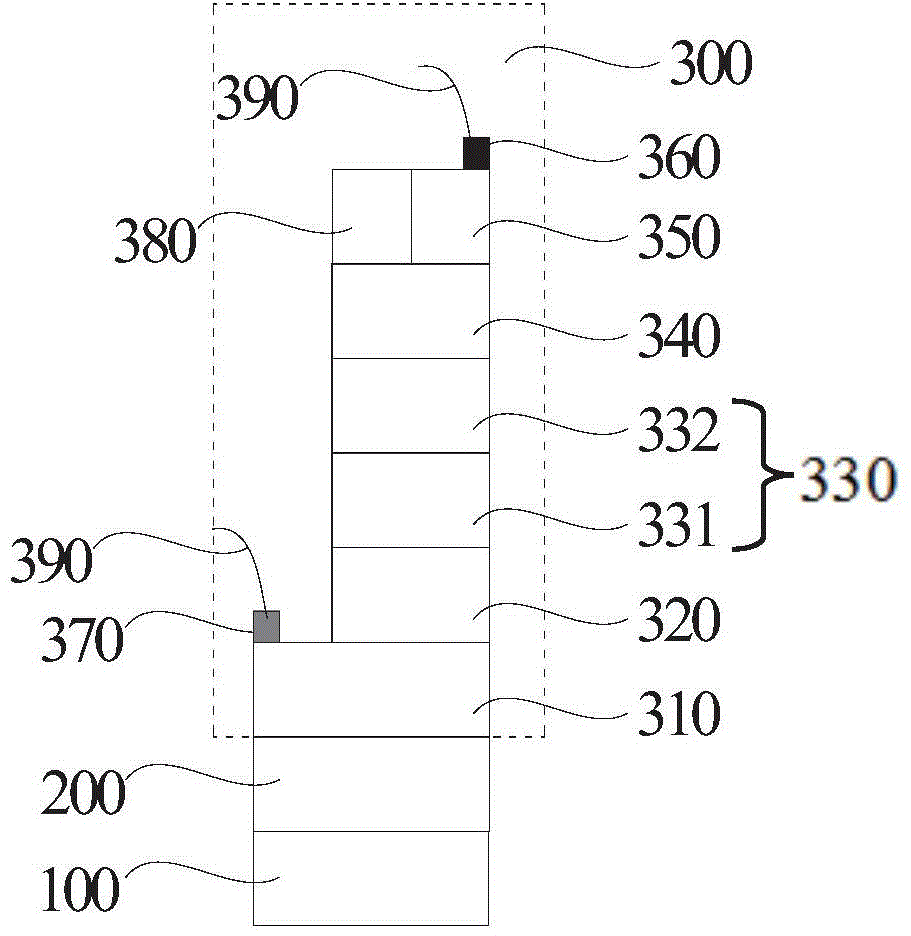

Photovoltaic device and preparation deice therefor

ActiveCN105742374AIncrease parallel resistanceImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationElectricityOxygen

The invention discloses a photovoltaic device, and the device comprises a substrate and a photovoltaic cell growing on the substrate. The device also comprises an Al2O3 material layer disposed between the substrate and the photovoltaic cell. The invention also discloses a preparation method for the photovoltaic device, and the method comprises the steps: A, growing an Al(Ga)As material layer on the substrate; B, growing the photovoltaic cell on the Al(Ga)As material layer; C, enabling the Al(Ga)As material layer to be laterally oxidized into the Al2O3 material layer through a wet-oxygen oxidation method, and forming a wet-oxygen oxidation layer. The photovoltaic device can effectively prevent a semi-insulating substrate from leaking electricity under solar radiation, also can increase the parallel resistance of the photovoltaic cell, and increases the conversion efficiency.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Method of improving parallel resistance in photovoltaic cells

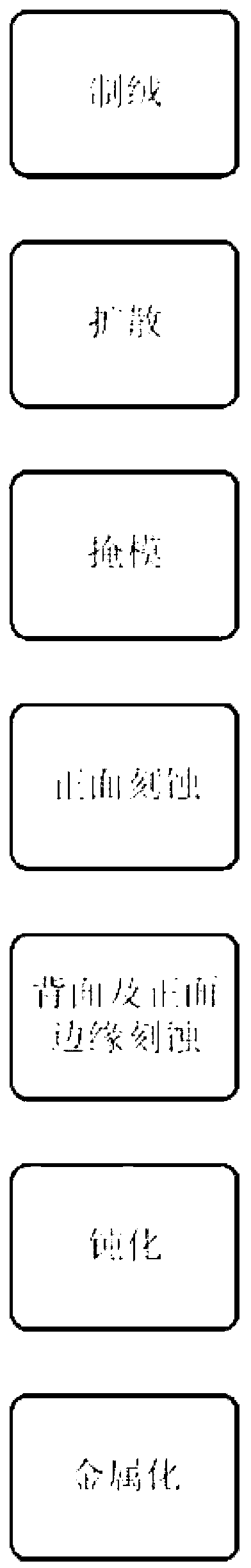

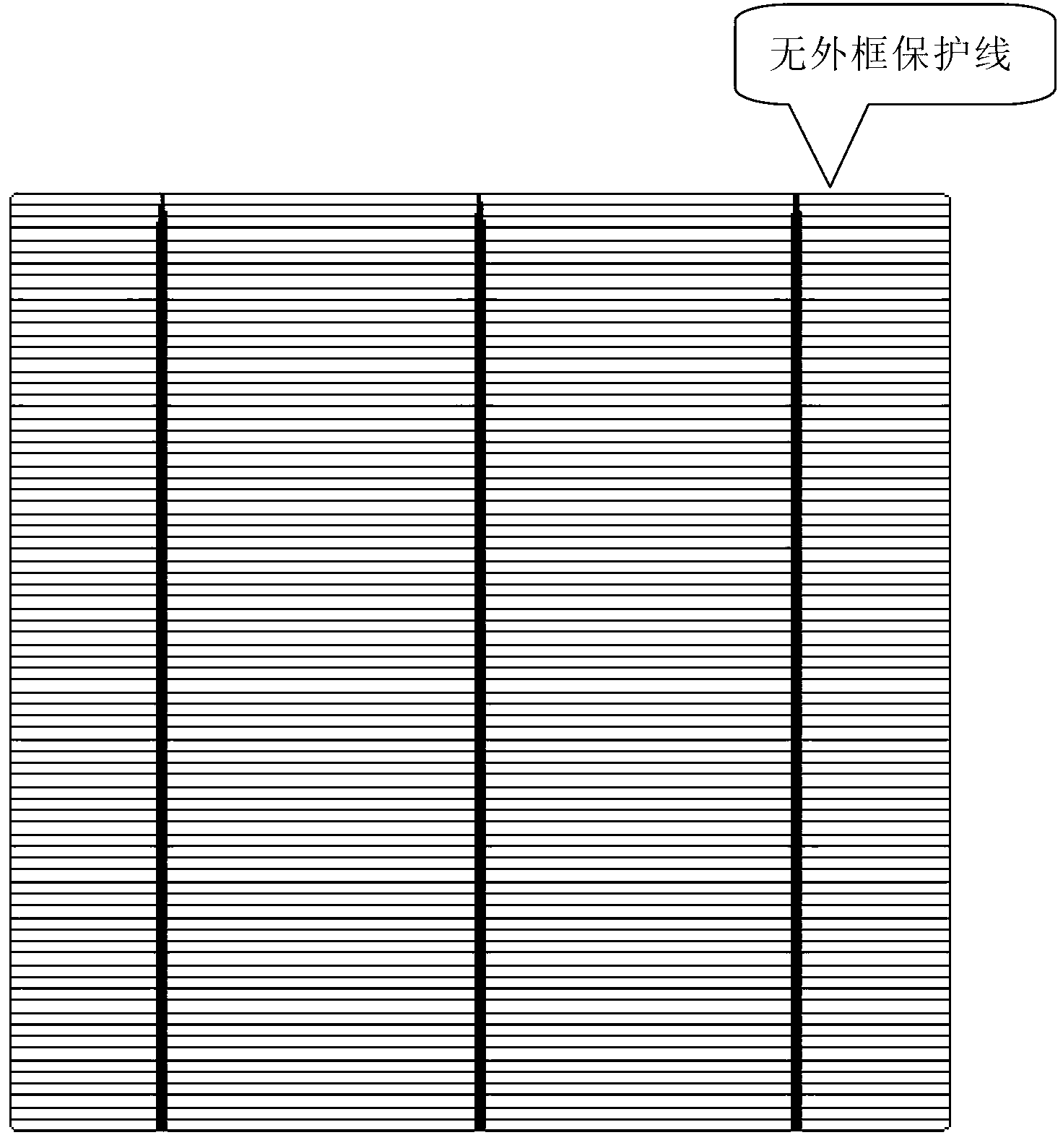

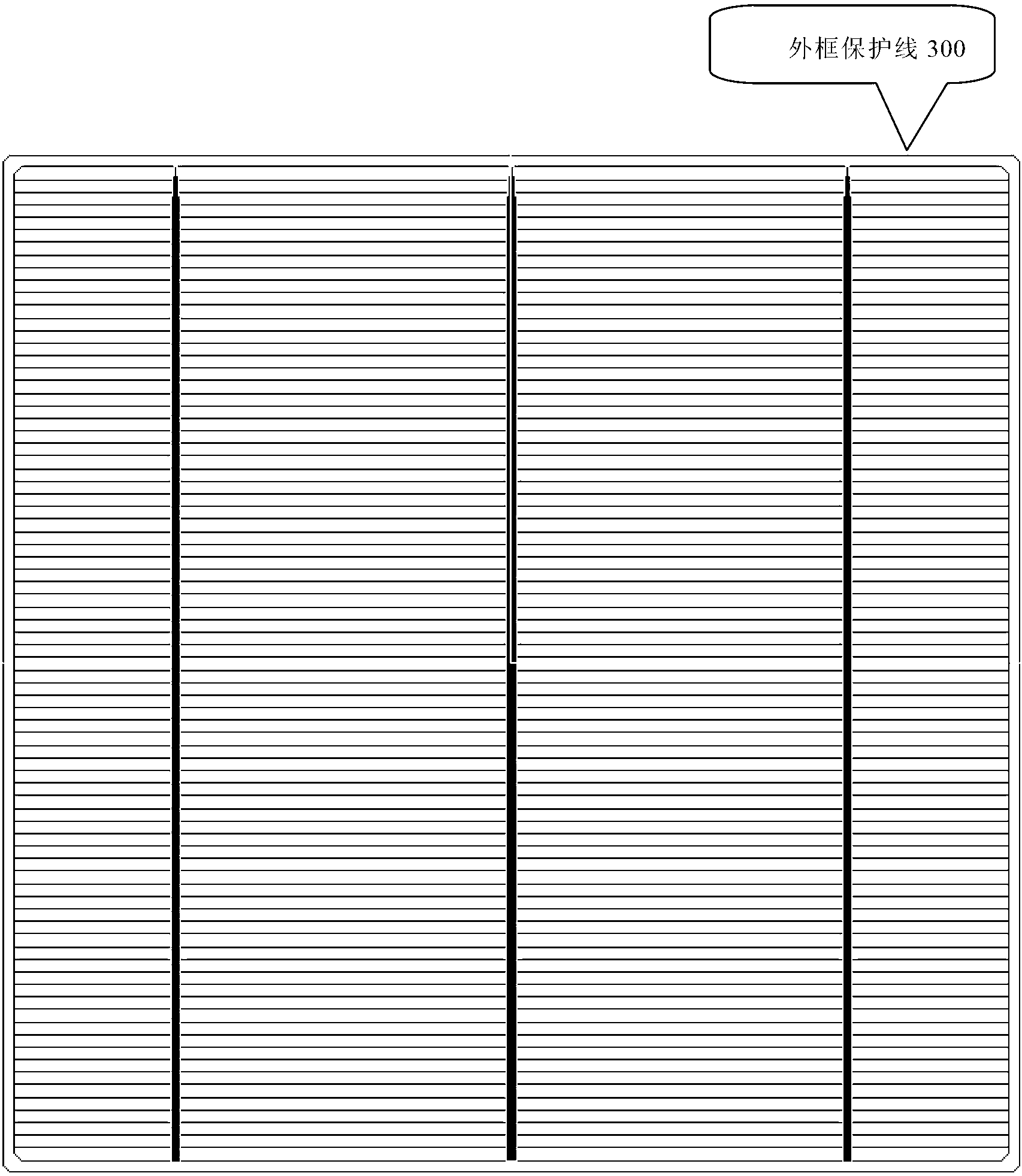

ActiveCN103311377AIncrease parallel resistanceImprove conversion efficiencyFinal product manufactureSemiconductor devicesSilicon

The invention discloses a method of improving parallel resistance in photovoltaic cells. A production process of a selective emitter junction cell includes: producing a silicon wafer comprising an emitter junction; setting a mask on the front surface of the silicon wafer to protect an area to be metalized on the front surface of the silicon wafer and the edge of the front surface of the silicon wafer; etching the front surface of the silicon wafer; removing the mask; and etching the edges of the back and front surfaces of the silicon wafer. The mask comprises a mask outer frame disposed at the edge of the front surface of the silicon wafer. The invention further discloses a selective emitter junction cell produced by the production process.

Owner:TRINA SOLAR CO LTD

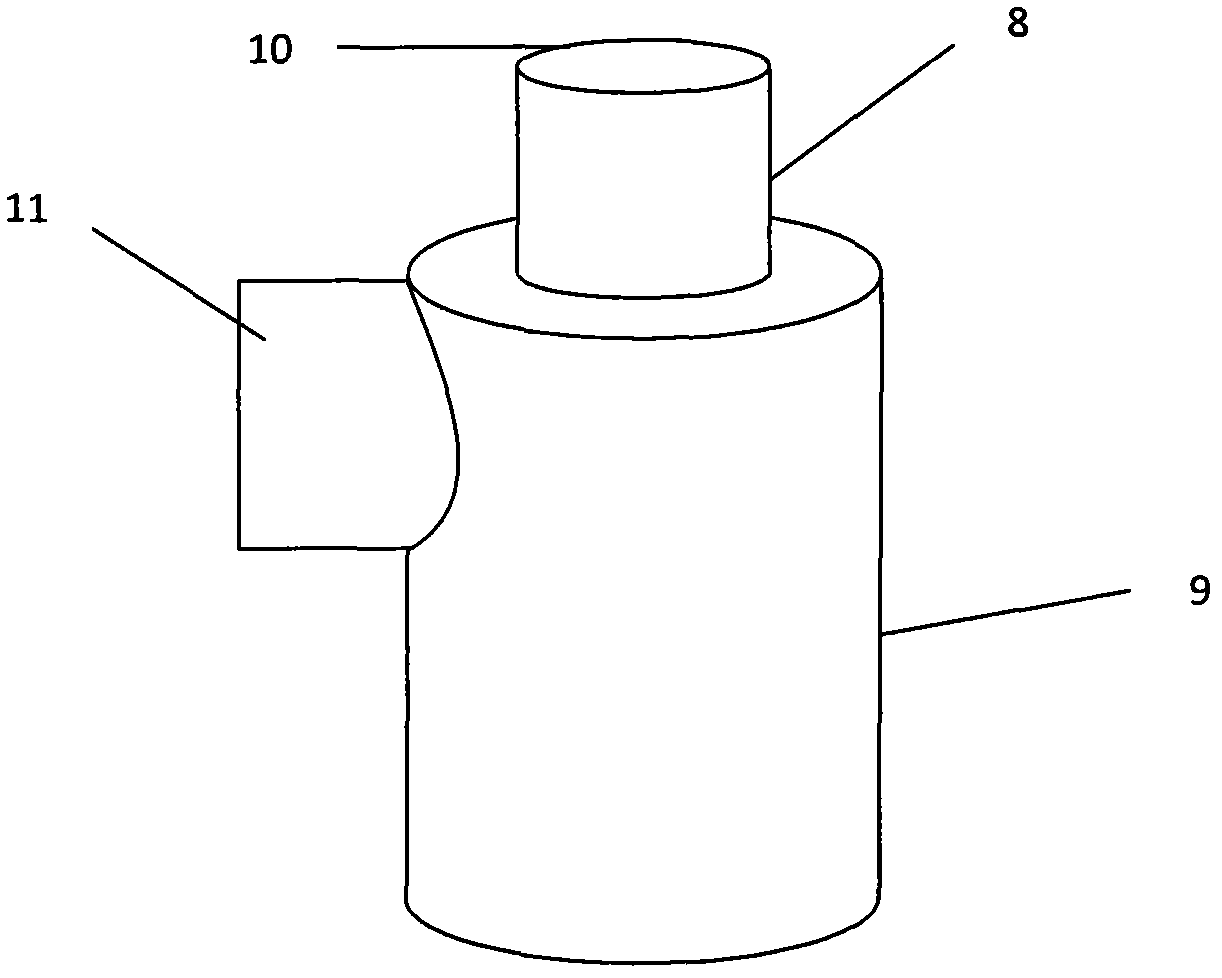

Dye-sensitized solar cell

InactiveCN102915848AEasy to operateLow costLight-sensitive devicesPhotovoltaic energy generationEngineeringSolar cell

The invention relates to a dye-sensitized solar cell which is characterized by comprising a first substrate, a second substrate and a photovoltaic conversion layer. The photovoltaic conversion layer is disposed between the first substrate and the second substrate and comprises an electrolytic condenser and dye adsorption units, and the dye adsorption units are distributed in the electrolytic condenser. The dye-sensitized solar cell and a diode are arranged on the top of a lampshade, is connected to a storage battery in a barrel through a conductor wire.

Owner:张陆成

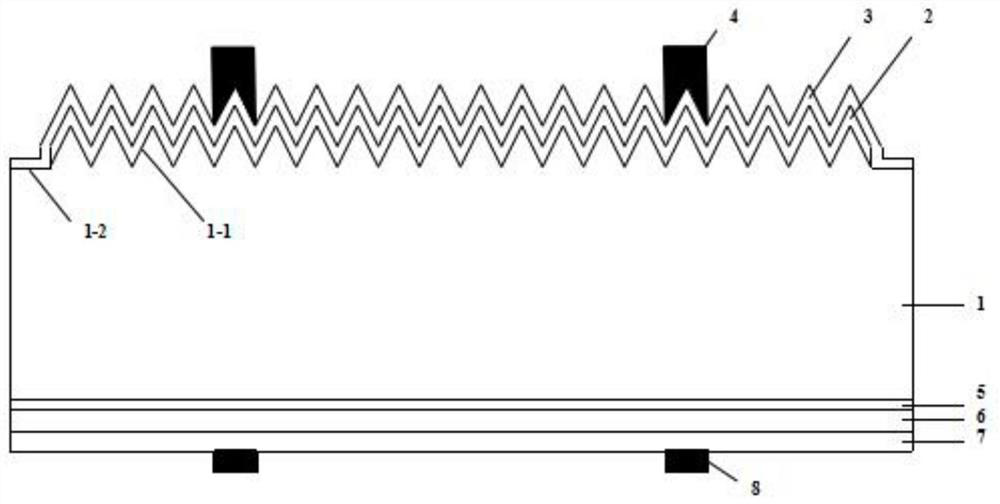

Solar cell and preparation method thereof

ActiveCN111834476AIncrease parallel resistanceImprove yieldPhotovoltaic energy generationSemiconductor devicesSolar cellBattery cell

The invention discloses a solar cell and a preparation method thereof, belongs to the technical field of solar cells, and solves the problems of relatively low cell yield and the like caused by relatively high leakage current of a solar cell in the prior art. The invention provides a solar cell. The solar cell comprises a silicon substrate body, the front face of the silicon substrate body comprises a first surface, the first surface comprises a doped region and a non-doped region, the non-doped region is distributed in the peripheral edge region of the doped region, the width of the non-dopedregion is not larger than 2 mm, and a doped layer is arranged on the upper surface of the doped region. The solar cell is low in leakage current.

Owner:JA SOLAR TECH YANGZHOU

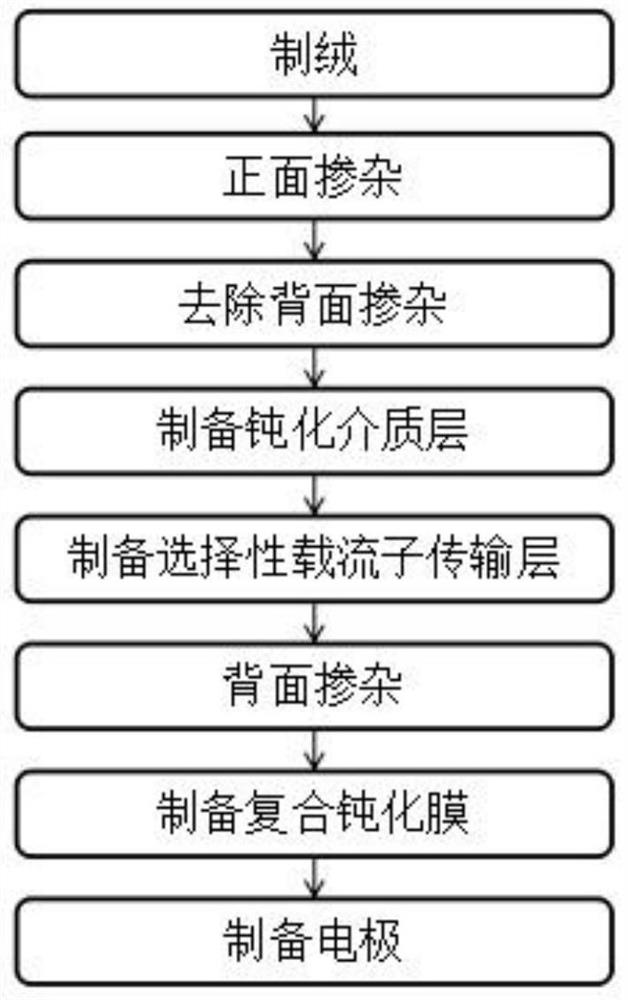

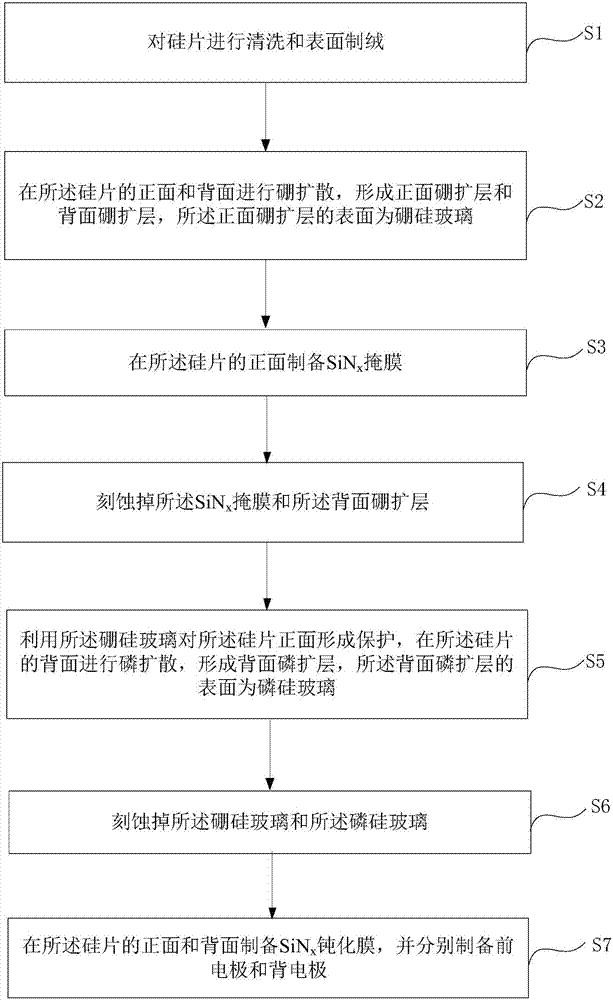

A kind of manufacturing method of n-type bifacial battery

ActiveCN106129173BReduce etch timeIncrease parallel resistanceFinal product manufactureSemiconductor devicesPorous siliconBorosilicate glass

The invention discloses a fabrication method of an N-type double-sized battery. The fabrication method comprises the following steps of cleaning a silicon wafer and texturing a surface; performing boron diffusion on a front surface and a back surface of the silicon wafer to form a front-surface boron diffusion layer and a back-surface boron diffusion layer, wherein borosilicate glass is arranged on a surface of the front-surface boron diffusion layer; fabricating an SiNx mask on the front surface of the silicon wafer; etching the SiNx mask and the back-surface boron diffusion layer; forming protection on the front surface of the silicon wafer by the borosilicate glass, and performing phosphorus diffusion on the back surface of the silicon wafer to form a back-surface phosphorus diffusion layer, wherein phosphorosilicate glass is arranged on a surface of the back-surface phosphorus diffusion layer; etching the borosilicate glass and the phosphorosilicate glass; and fabricating SiNx passivation films on the front surface and the back surface of the silicon wafer, and separately fabricating a front electrode and a back electrode. By the above method, the HF etching time can be reduced, porous silicon on the back surface is prevented from forming, thus, the combination of the back surface of the battery is effectively reduced, the parallel resistance and the open-circuit voltage of the battery are increased, and the battery efficiency is improved.

Owner:ZHEJIANG JINKO SOLAR CO LTD +1

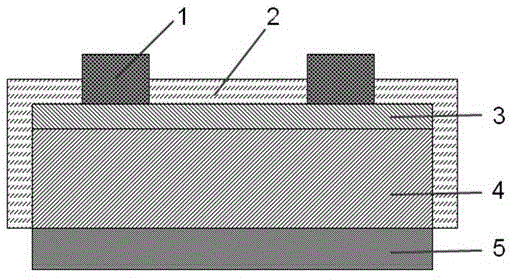

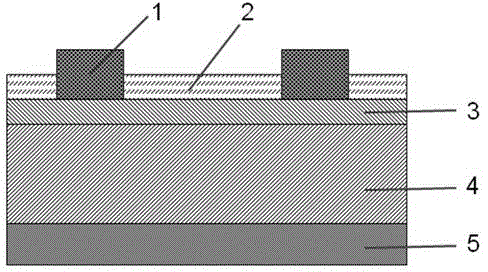

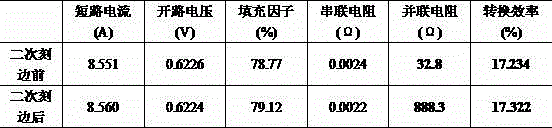

Crystalline silicon cell and manufacturing method thereof

ActiveCN104538498ASimple methodEasy to operateFinal product manufacturePhotovoltaic energy generationEtchingDeposition process

The invention provides a crystalline silicon cell and a manufacturing method of the crystalline silicon cell. The method includes the following steps of texture surface making, diffusion junction making, edge etching, phosphorosilicate glass removal, silicon nitride antireflection layer deposition, electrode printing, sintering and test sorting. The secondary edge etching process is introduced in the steps, a silicon nitride layer on the edge of a crystalline silicon cell piece is removed, the parallel resistance of the crystalline silicon cell is increased, and the photoelectric conversion efficiency of the crystalline silicon cell is improved. In addition, the secondary edge etching process can be selectively introduced after the silicon nitride antireflection layer deposition process and the silicon nitride layer on the edge of the cell is removed; or the secondary edge etching process can be selectively introduced after the sintering process and the silicon nitride layer on the edge of the cell is removed. The method is simple, easy to operate and free of limitation to other process steps.

Owner:ZHEJIANG BEYONDSUN PV

High-sensitivity organic photodiode, array formed thereby and preparation method of high-sensitivity organic photodiode

PendingCN113823744AImprove external quantum efficiencyImprove spectral responsivitySolid-state devicesSemiconductor/solid-state device manufacturingQuantum efficiencyHeterojunction

The invention relates to a high-sensitivity organic photodiode which comprises a photosensitive layer, wherein the photosensitive layer is of a bulk heterojunction structure, that is, (i) the photosensitive layer comprises a donor material D1 and an acceptor material A1; and donor materials D2-Dn, wherein the energy gap of the donor materials D2-Dn is larger than the energy gap of the donor material D1 and / or the energy gap of the acceptor material A1; or (ii)the photosensitive layer comprises a donor material D1 and an acceptor material A1; and acceptor materials A2-An, wherein the energy gap of the acceptor materials A2-An is larger than the energy gap of the donor material D1 and / or the energy gap of the acceptor material A1. Due to the addition of new components in the photosensitive layer, the defect state density of impurities in a bulk heterojunction energy gap is effectively reduced, a trap auxiliary composite channel of photogenerated charges is inhibited, the external quantum efficiency is enhanced, dark current is reduced, and the specific detection rate of the device is further improved. The invention also relates to an array formed by the same and a related preparation method.

Owner:GUANGZHOU GUANGDA INNOVATION TECH CO LTD

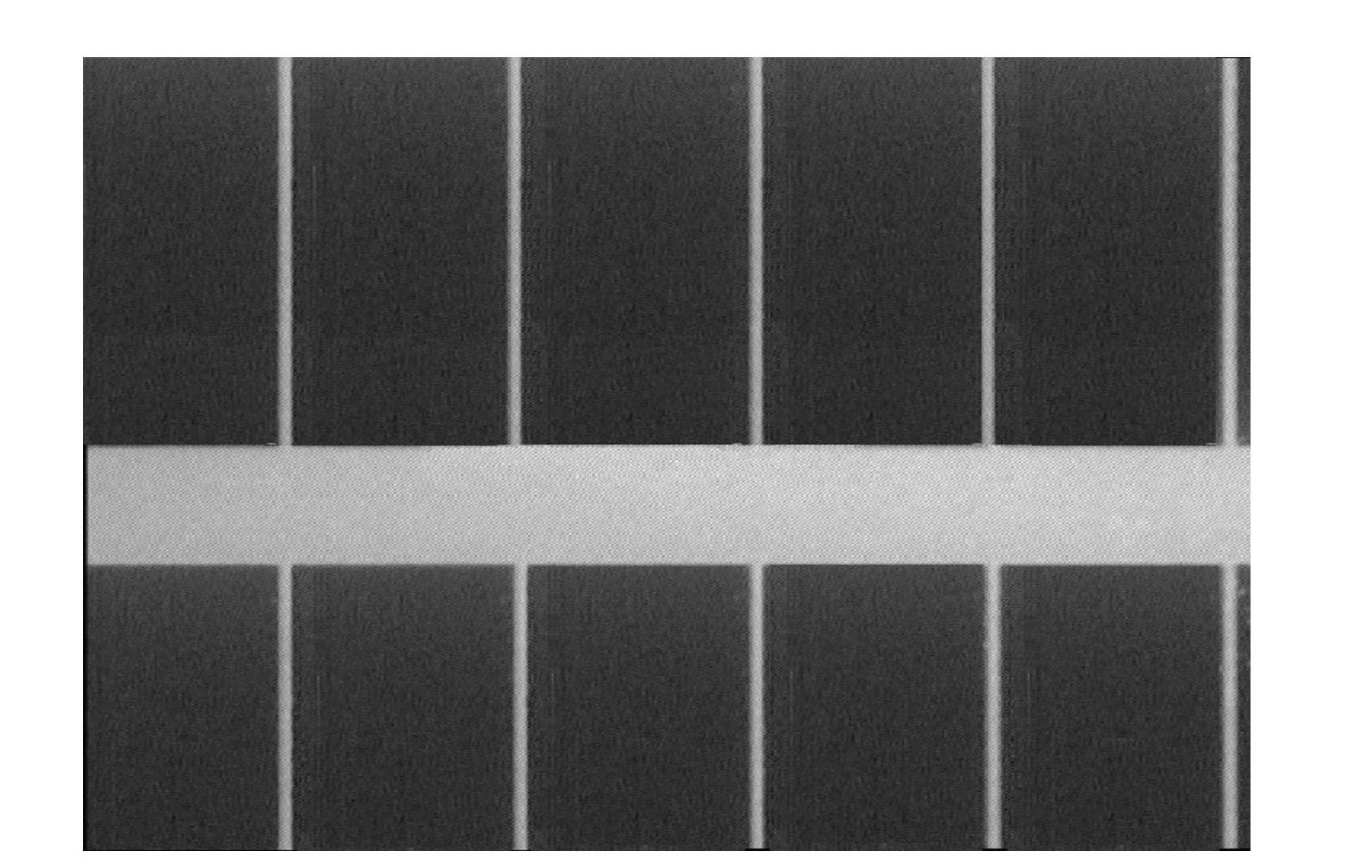

Method for preparing first scribed line and third scribed line of thin-film solar cell

ActiveCN111900219AImprove output efficiencyDoes not reduce the effective use areaFinal product manufacturePhotovoltaic energy generationScreen printingThin membrane

The invention discloses a method for preparing a first scribed line and a third scribed line of a thin-film solar cell. The method mainly comprises the following steps that an insulating layer is formed on a first scribed line, and / or an insulating layer is formed on a third scribed line, the width of the insulating layer is 3-5 microns wider than that of the corresponding scribed line, and the thickness of the insulating layer is 100-5000 nanometers; the method for forming the insulating layer comprises a silk-screen printing method, a screen evaporation method and an ink-jet printing method,and the insulating layer is composed of transparent insulating substances. The invention further discloses a scribing method of the thin-film solar cell. By adopting the method provided by the invention, the parallel resistance and the open-circuit voltage can be improved on the premise of not reducing the effective utilization area of the thin-film solar cell module, and the output efficiency ofthe thin-film solar cell is improved.

Owner:唐山科莱鼎光电科技有限公司

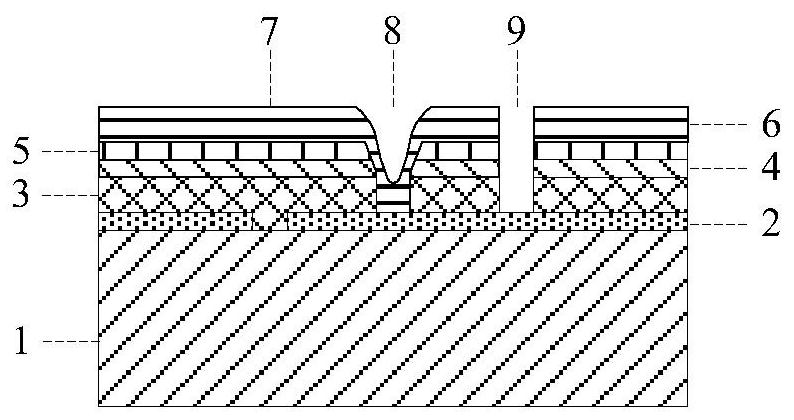

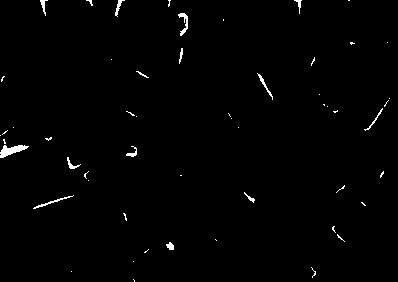

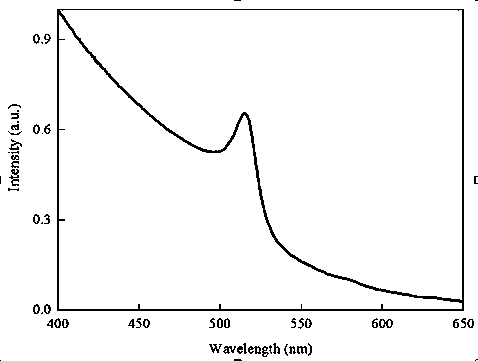

A kind of phthalocyanine dye-sensitized cspbbr3 photovoltaic cell and its manufacturing method

ActiveCN107123741BImprove flatness defectsImprove overall lifespanFinal product manufactureSolid-state devicesPhthalocyanine dyeEngineering

The invention relates to the technical field of inorganic perovskite CsPbBr3 thin film photovoltaic cells, in particular to a phthalocyanine dye-sensitized CsPbBr3 thin film photovoltaic cell and a manufacturing method thereof. The phthalocyanine dye-sensitized CsPbBr3 photovoltaic cell comprises a transparent conductive substrate, a hole transport layer, a CsPbBr3 film photosensitive layer, a dye-sensitized layer, an electron transport layer, an electrode modification layer and a reflective electrode. The invention can improve the energy conversion efficiency and service life of the CsPbBr3 photovoltaic cell.

Owner:周孝银

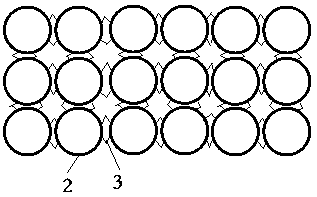

Film photovoltaic device and manufacturing method thereof

ActiveCN108695405AIncrease electrical couplingImprove mobilityFinal product manufactureSolid-state devicesCross-linkNanoparticle

The invention discloses a film photovoltaic device and a manufacturing method thereof. The method comprises the following steps of step A, depositing a light absorption layer on a first electrode; step B, depositing an electronic extraction layer on the light absorption layer, wherein the material of the electronic extraction layer is a cross-linked nano-particle film formed through carrying out crosslinking treatment on a nanoparticle film; and step C, evaporating a second electrode on the electronic extraction layer and acquiring the film photovoltaic device. In the invention, the acquired cross-linked nano-particle film is applied in the film photovoltaic device manufactured through a solution method, a parallel resistance in the photovoltaic device can be greatly increased and a seriesresistance in the photovoltaic device is reduced so that the light current of a fill factor in the film photovoltaic device is increased, and then the photoelectric conversion efficiency of the device is improved.

Owner:TCL CORPORATION

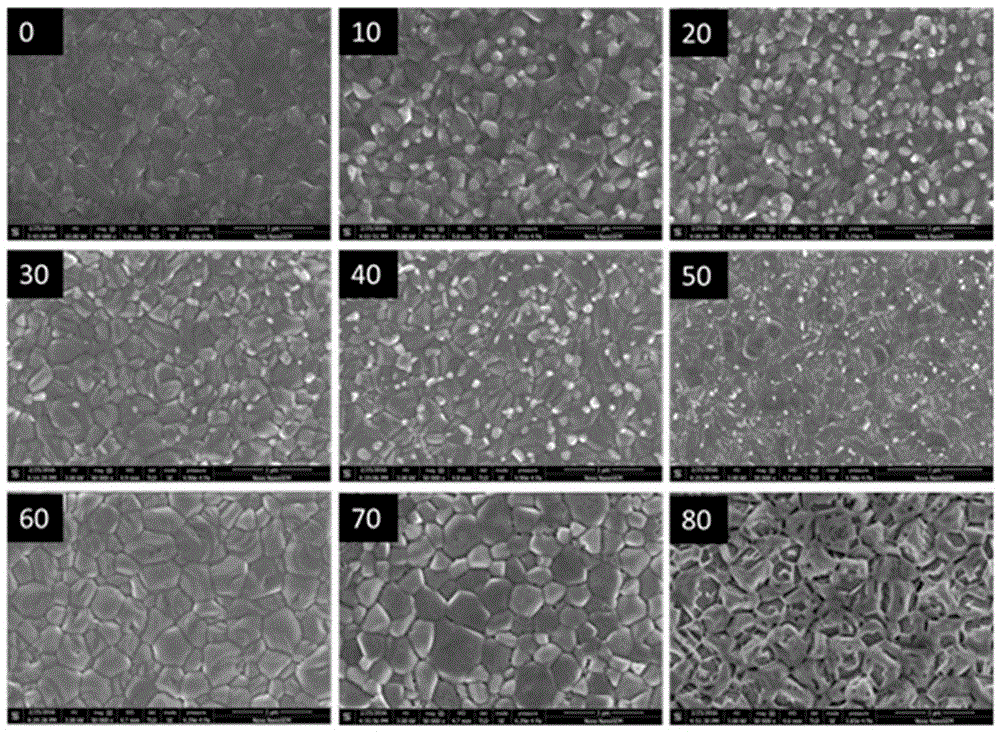

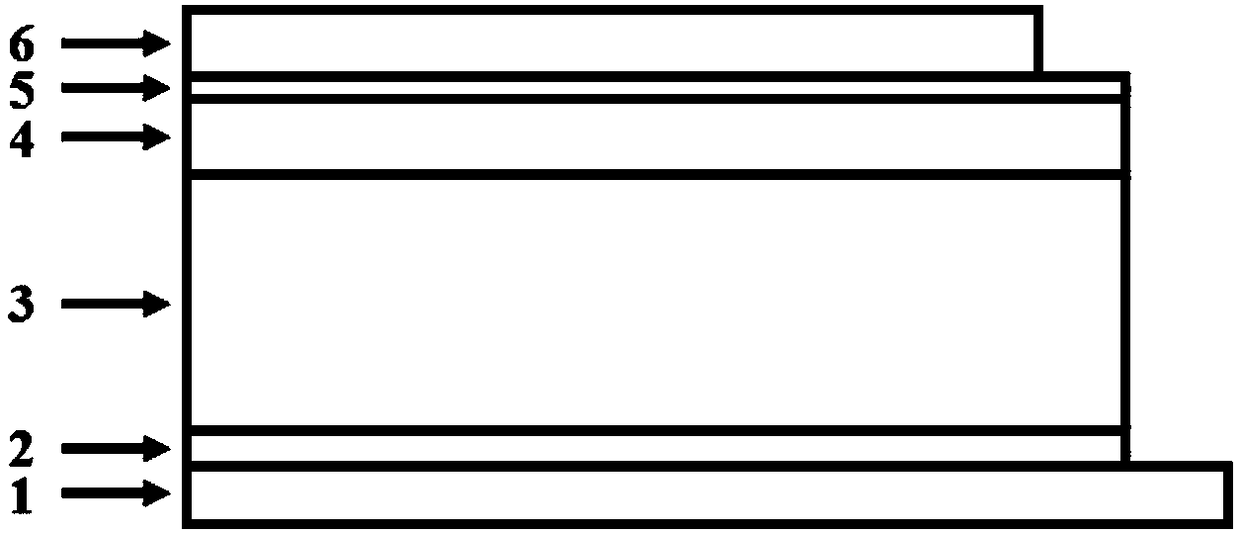

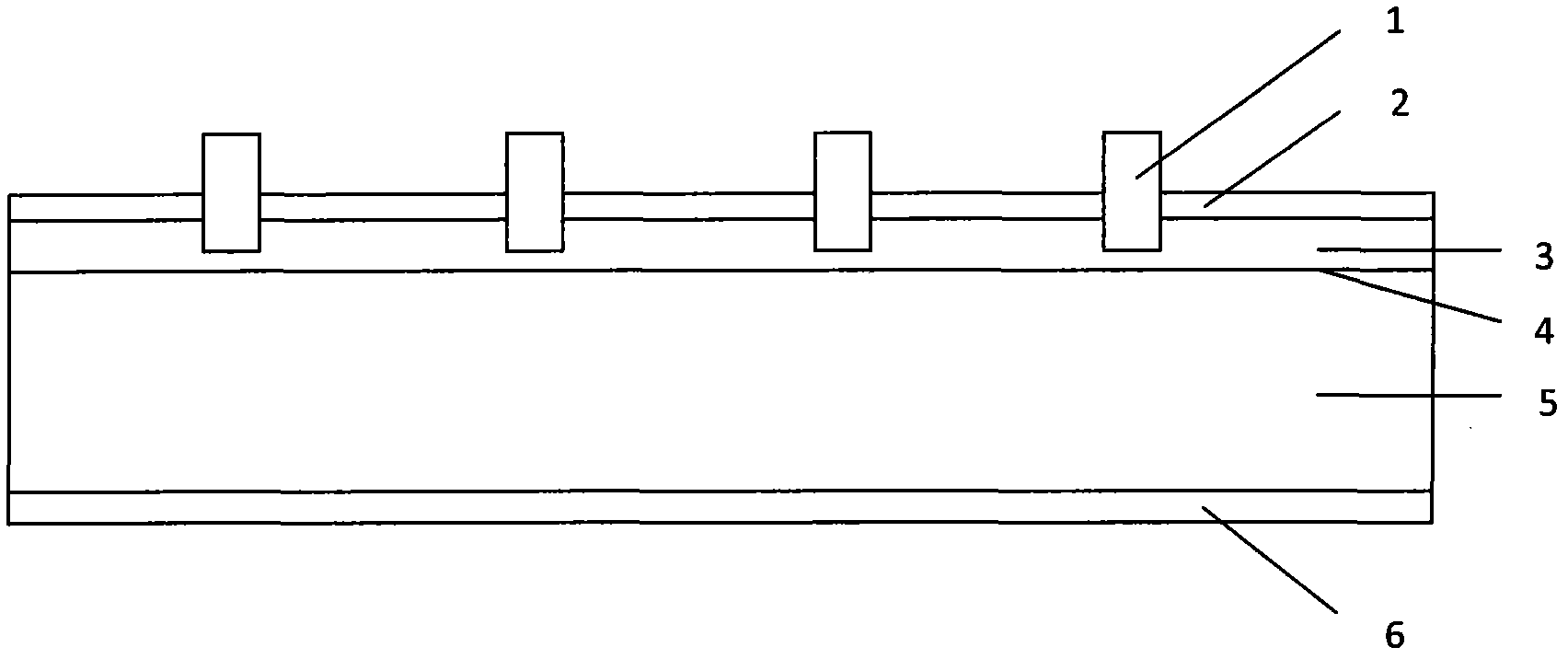

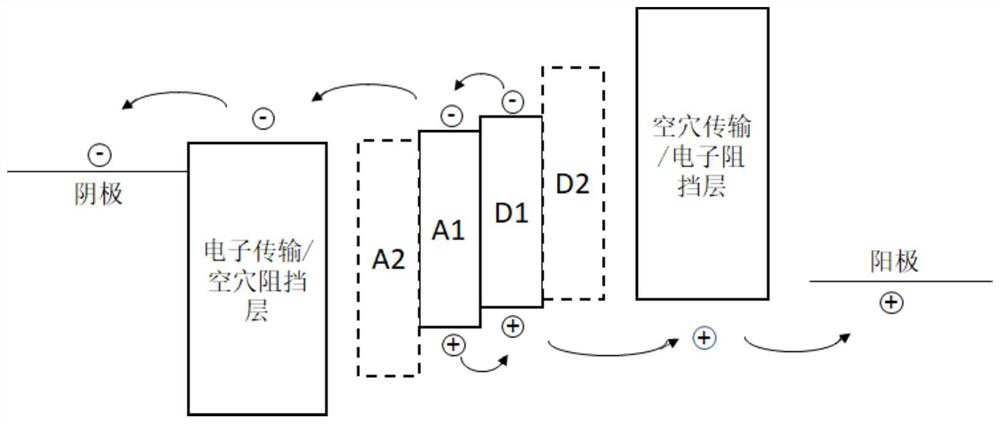

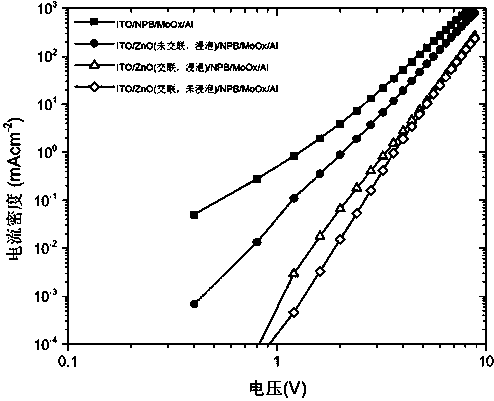

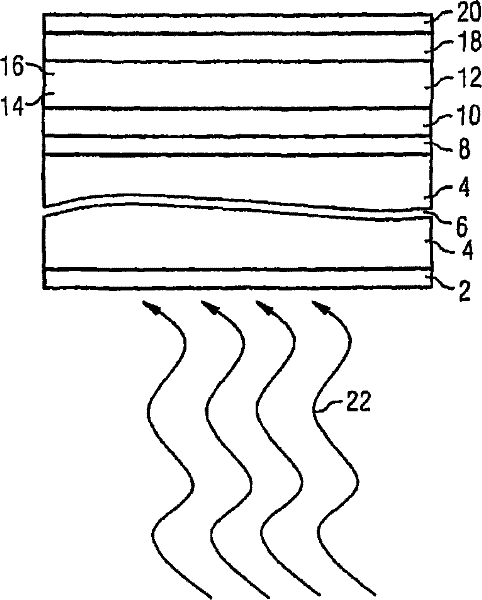

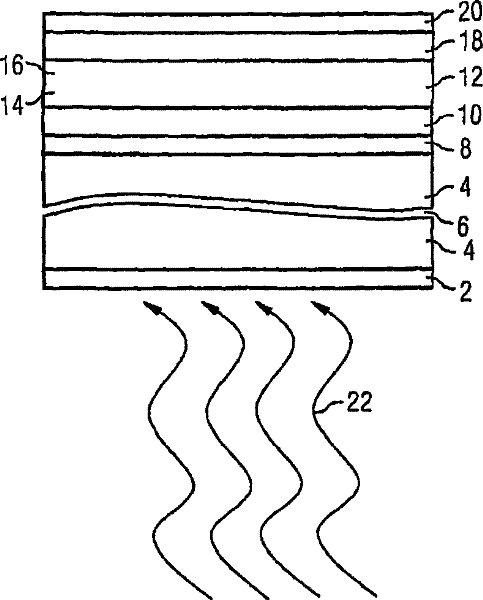

Organic solar cell comprising an intermediate layer with asymmetrical transport properties

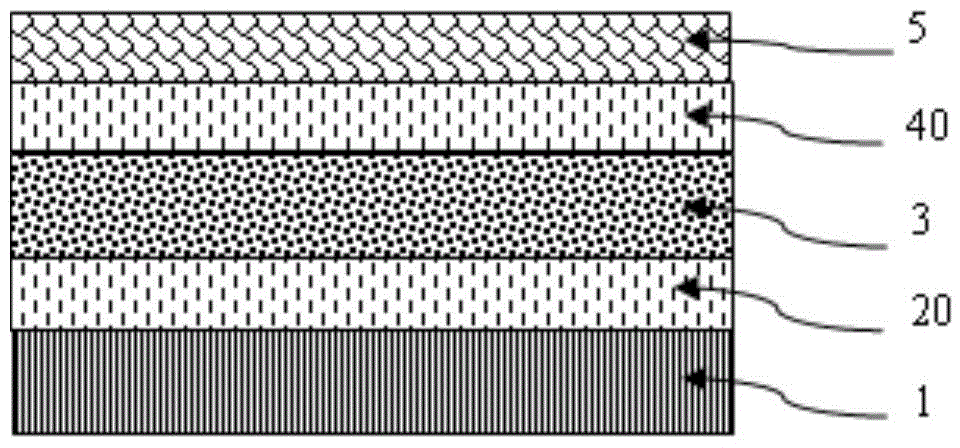

ActiveCN1806349AIncrease parallel resistanceReduce lossNanoinformaticsSolid-state devicesOrganic solar cellNon symmetric

The solar cell has an antireflection layer (2) on the outside of a transparent plastics, glass or crystalline substrate (4). A first layer on the inner side of the substrate is an electrode (8). It may act either as the cathode or the anode and may be made of aluminum, copper or ITO (Indium Tin Oxide). A first intermediate layer (10) has an asymmetrical conductivity and acts as an electron acceptor. It also acts as an optical antireflection layer. The next active layer (12) has an electron acceptor side (14) contacting the first intermediate layer and an electron donor side (16) contacting a second intermediate layer (18) and an electrode layer (20).

Owner:MERCK PATENT GMBH

Organic solar cell comprising an intermediate layer with asymmetrical transport properties

ActiveCN1806349BIncrease parallel resistanceReduce lossNanoinformaticsSolid-state devicesElectronPhysics

The invention relates to an organic solar cell comprising a photoactive layer consisting of two molecular components, namely an electron donator and an electrode acceptor, and comprising two electrodes provided on both sides of the photoactive layer, whereby an intermediate layer having an asymmetric conductivity is placed between at least one of the electrodes and the photoactive layer.

Owner:MERCK PATENT GMBH

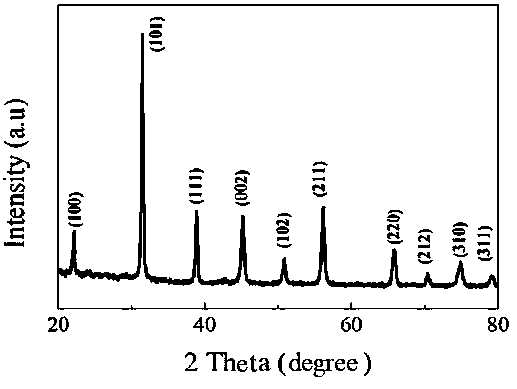

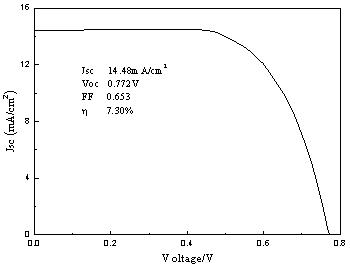

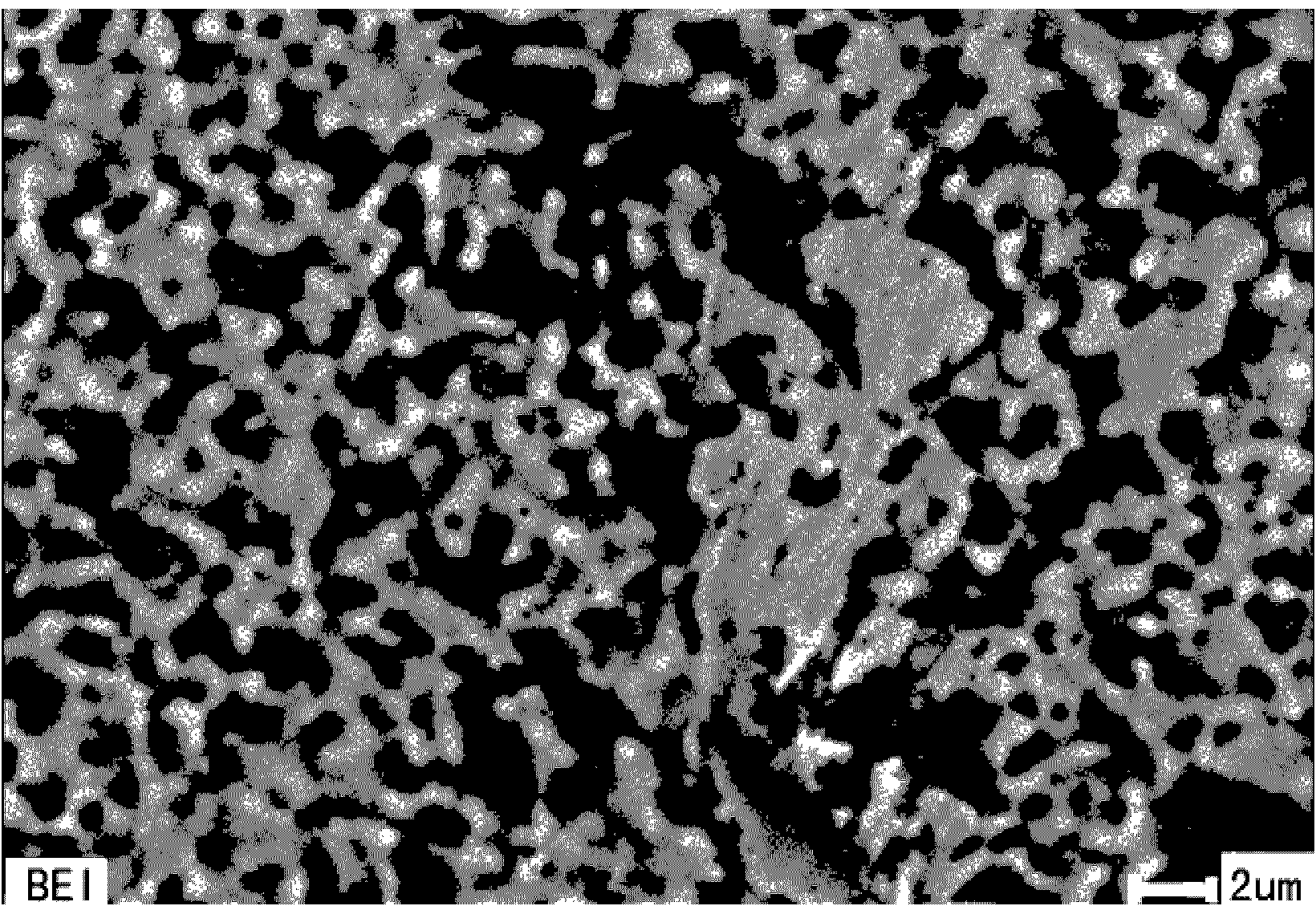

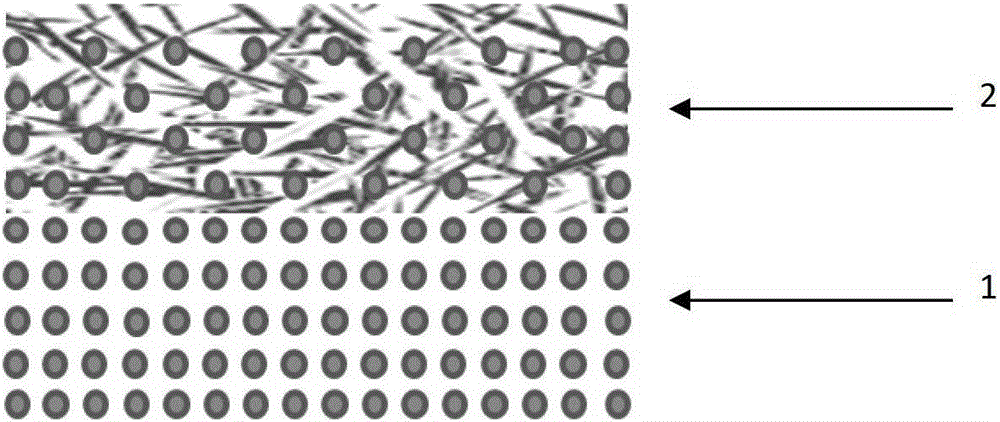

Solar cell photoanode based on three-dimensional tio2 nano-network material and preparation method thereof

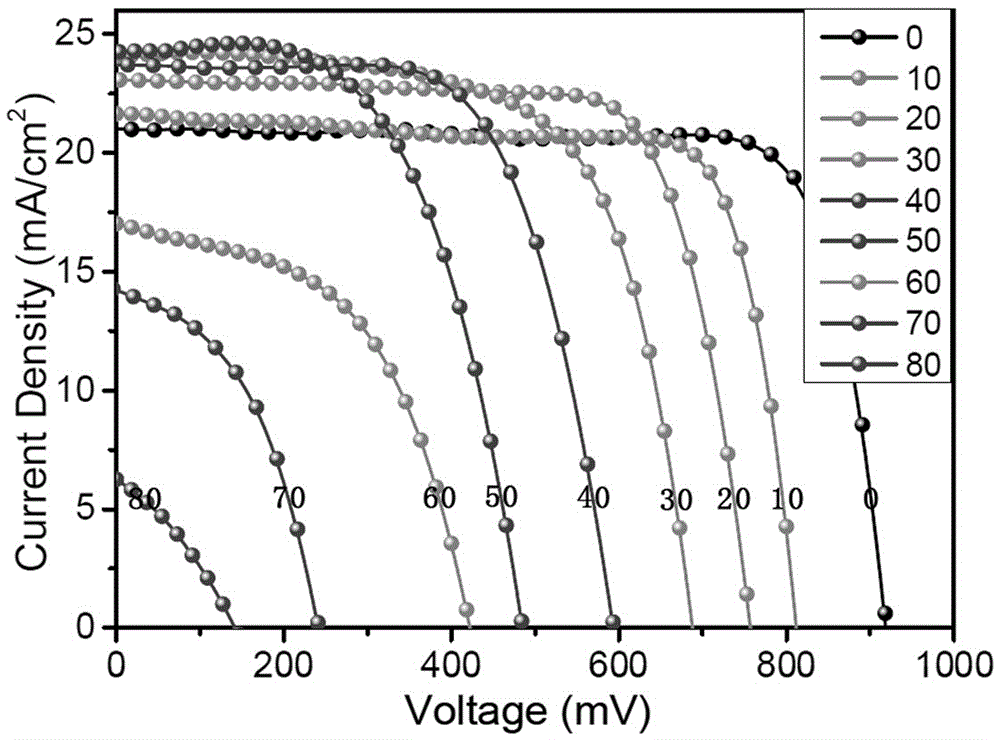

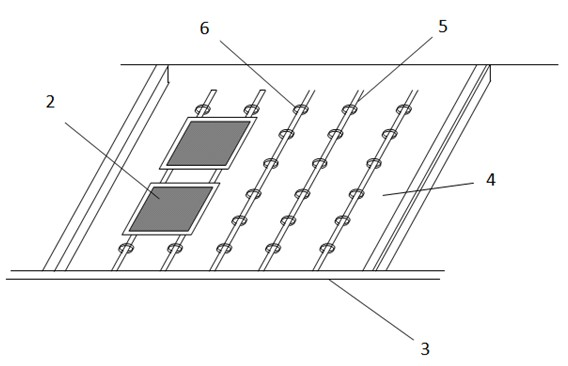

ActiveCN103165291BImprove efficiencyIncrease parallel resistanceLight-sensitive devicesPhotovoltaic energy generationAbsorption capacityPhotocurrent

The invention discloses a solar cell photo-anode based on a three-dimensional TiO2 nano mesh material, and a preparation method of the solar cell photo-anode, and belongs to the field of dye-sensitized solar cells. The solar cell photo-anode consists of a coating 1 and a coating 2 on fluorine-doped tin oxide (FTO) conductive glass, wherein the coating 1 is titanium dioxide of which the thickness is 4 to 8 mm; the coating 2 is a mixture of the titanium dioxide and the three-dimensional TiO2 nano mesh material; the thickness of the mixture is 4 to 8 mm, and the mass ratio of the titanium dioxide to the three-dimensional TiO2 nano mesh material is 1:1; and the coating 2 is positioned on the coating 1. By adoption of a photo-anode thin film structure, the parallel resistance of a cell can be effectively improved, and series resistance is reduced, so the probability of electron recombination is reduced, the transmission efficiency of electrons is improved, and the capture absorption capacity of sunlight in a dye adsorption state can be improved. On the basis of the two characteristics of the photo-anode thin film structure, the photo current density and photoelectric conversion efficiency of the dye-sensitized solar cell are greatly improved.

Owner:JILIN UNIV

A kind of thin film photovoltaic device and its preparation method

ActiveCN108695405BIncrease electrical couplingImprove mobilityFinal product manufactureSolid-state devicesNanoparticleFill factor

The invention discloses a thin-film photovoltaic device and a preparation method thereof, wherein the method comprises: step A, depositing a light-absorbing layer on a first electrode; step B, depositing an electron extraction layer on the light-absorbing layer, and the electron extraction layer The material is a cross-linked nano-particle film formed by cross-linking treatment of the nano-particle film; step C, evaporating the second electrode on the electron extraction layer to obtain a thin-film photovoltaic device. In the present invention, the obtained cross-linked nanoparticle film is applied to the thin-film photovoltaic device prepared by the solution method, which can significantly increase the parallel resistance in the photovoltaic device and reduce the series resistance in the photovoltaic device, thereby increasing the photocurrent of the fill factor in the thin-film photovoltaic device , thereby improving the photoelectric conversion efficiency of the device.

Owner:TCL CORPORATION

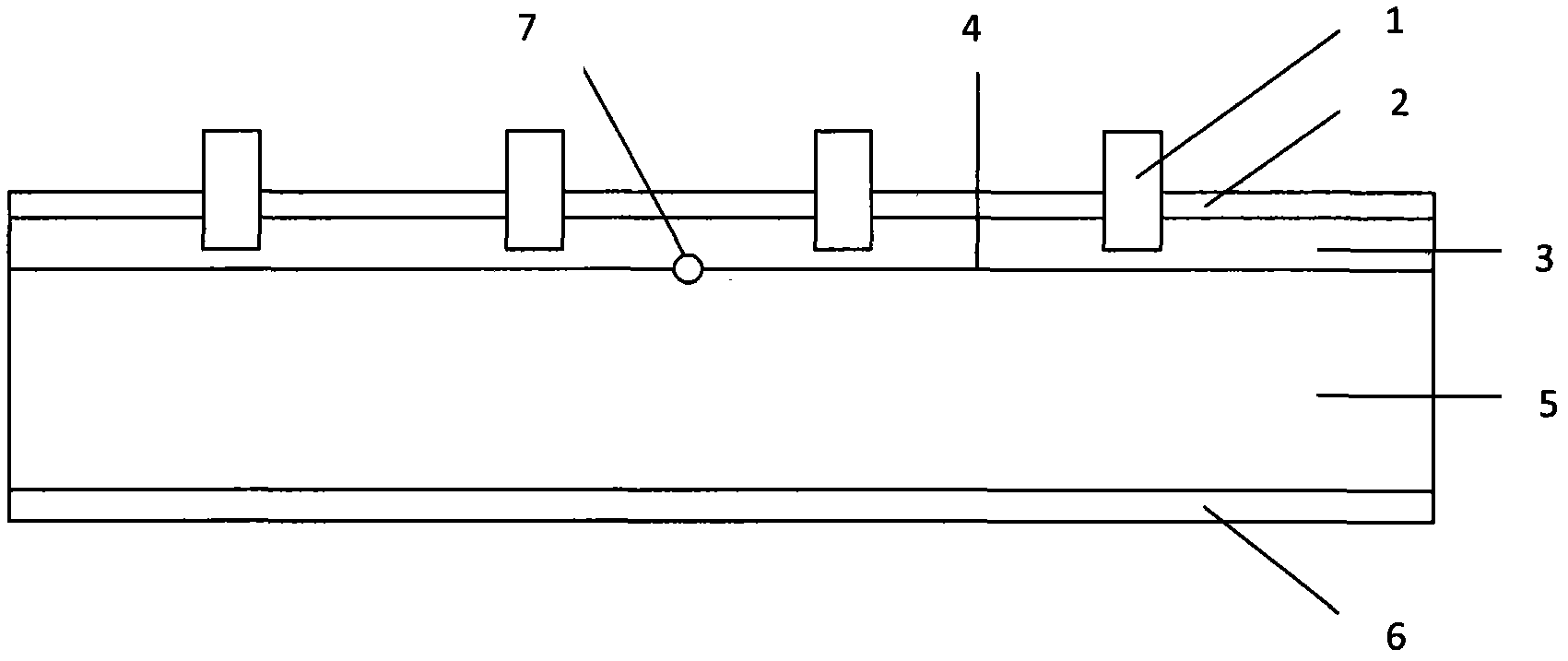

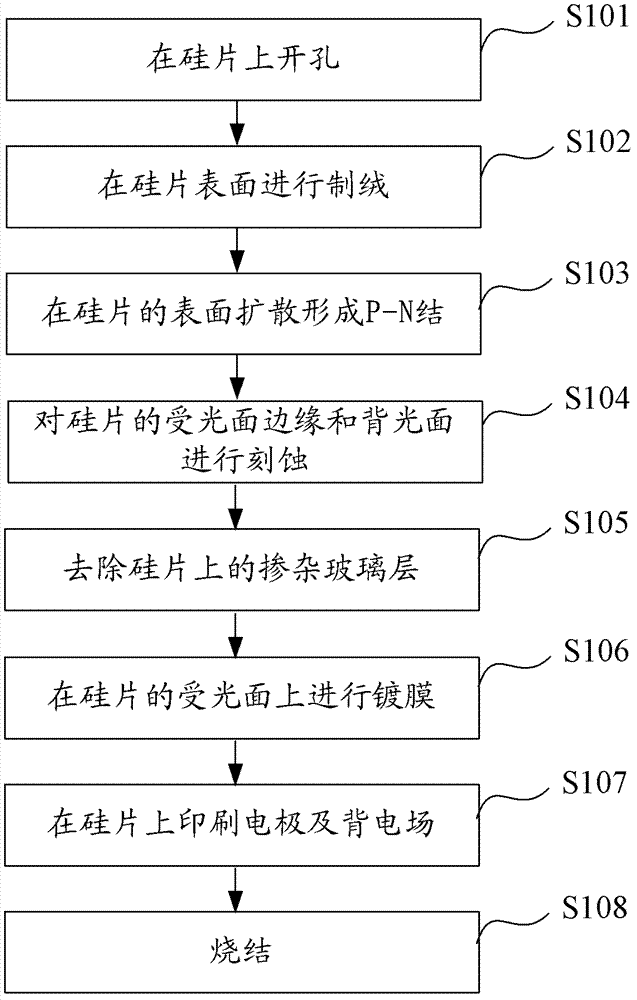

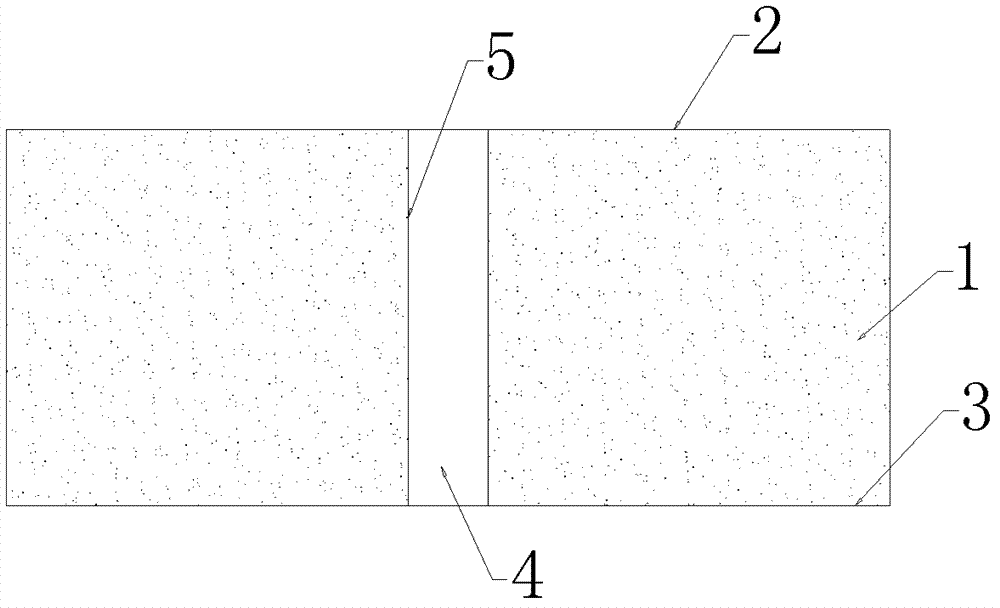

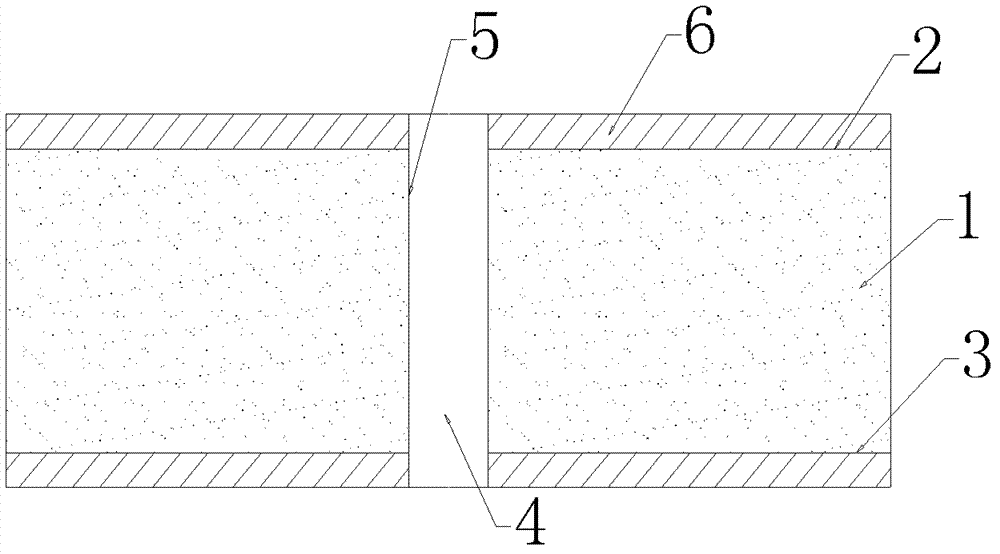

Method for manufacturing back contact crystalline silicon solar battery piece

ActiveCN102800741BIncrease parallel resistanceImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationEtchingBreakage rate

A method for manufacturing a back contact crystalline silicon solar cell sheet is provided. The method comprises: forming a via (4) on a semiconductor wafer (1); performing texturing and diffusion processes on surfaces (2, 3) of the semiconductor wafer; etching the diffused semiconductor wafer and performing the subsequent processes, thus obtaining the back contact crystalline silicon solar cell sheet, wherein the etching includes etching the backlight surface (3) and the edge of the light receiving surface (2) of the semiconductor wafer. In the method, the edge of the light receiving surface of the wafer and the emitter junction formed by diffusing on the backlight surface of the wafer are removed by etching at the same time. So there is not a short circuit conductive layer between the backlight surface and the conductive via of the solar cell sheet. Compared with the prior art, the method avoids the laser isolating process and then reduces the risk of leakage and the breakage rate of the cell sheet.

Owner:盐城阿特斯阳光能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com