Organic solar cell comprising an intermediate layer with asymmetrical transport properties

An intermediate layer, asymmetric technology, applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve problems such as there is no known solution to improve parallel resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

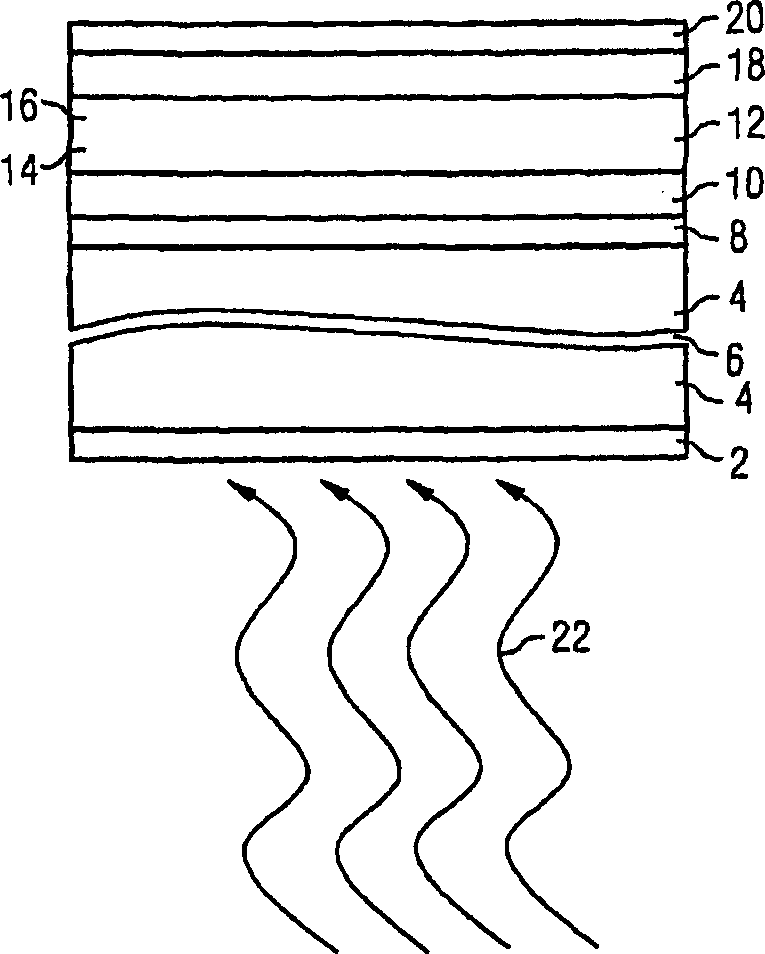

[0023] figure 1 A cross section of a solar cell according to an embodiment of the present invention is shown. The solar cell is seated on a carrier material or substrate 4 . The substrate 4 can be made of glass, plastic, crystal and other materials. The substrate 4 is shown with a burst line 6 to show that the thickness of the substrate 4 is not critical to the invention and is variable. The substrate serves only to provide the solar cell with a corresponding mechanical stability and, if necessary, to provide surface protection. The side of the substrate facing the incident light is coated with an anti-reflection layer 2 to avoid loss due to reflection.

[0024] The first layer 8 on the substrate is the electrode of the solar cell. It is not important whether the electrode is a cathode or an anode.

[0025] It is assumed here, without limitation, that light enters the solar cell shown through the substrate 4 from below. Therefore, the first electrode 8 should consist of,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com