Solar cell photoanode based on three-dimensional tio2 nano-network material and preparation method thereof

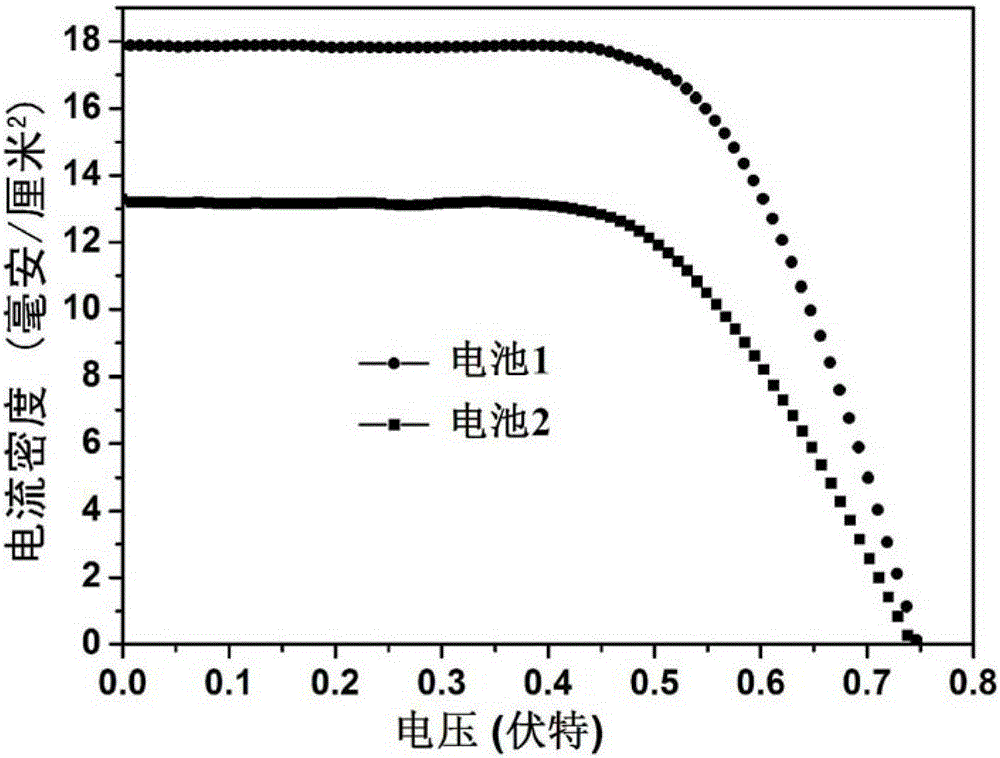

A technology of solar cells and mesh materials, applied in the field of dye-sensitized solar cells, can solve the problems of inconspicuous inter-particle bridging, reduce inter-particle bridging, and increase electron transmission resistance, so as to reduce the probability of electron recombination and increase Effects of trapping absorption ability and increasing photocurrent density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

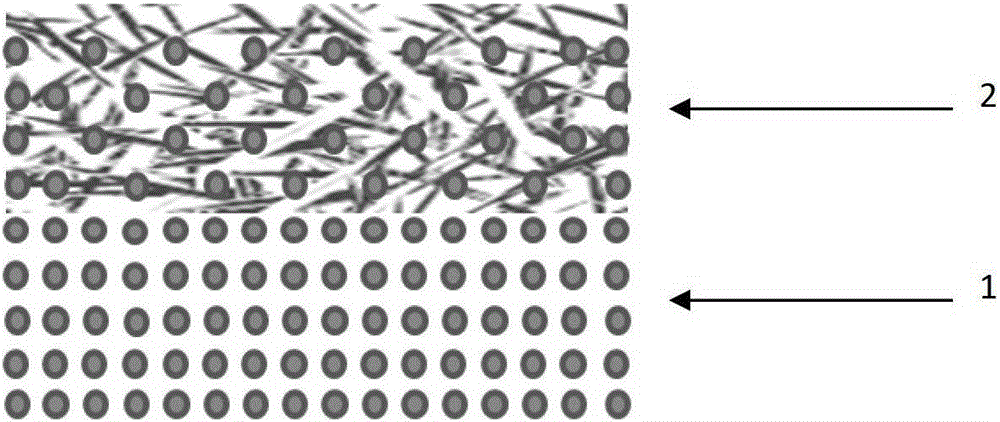

[0035] Embodiment 1: Based on three-dimensional TiO 2 The preparation of the photoanode structure of the dye-sensitized solar cell of the nano-network material, the specific process is as follows:

[0036] (1) Prepare two kinds of slurries, one is the slurry containing commercial titanium dioxide (P25, manufacturer Degussa), named slurry 1 (0.3g commercial titanium dioxide is added to 5mL ethanol and 1g terpineol mixed solution, ultrasonically stirred for 60 minutes to get). The other contains commercial titanium dioxide (P25, manufacturer Degussa) and three-dimensional TiO 2 The slurry prepared by mixing nano-mesh materials in a mass ratio of 1:1 is named slurry 2 (0.15g commercial titanium dioxide and 0.15g three-dimensional TiO 2 The nano-mesh material was added to a mixed solution of 5mL ethanol and 1g terpineol, and ultrasonically stirred for 60 minutes).

[0037] (2) Apply slurry 1 to fluorine-doped SnO by scraping method 2 (SnO 2 F) The surface of conductive glass ...

Embodiment 2

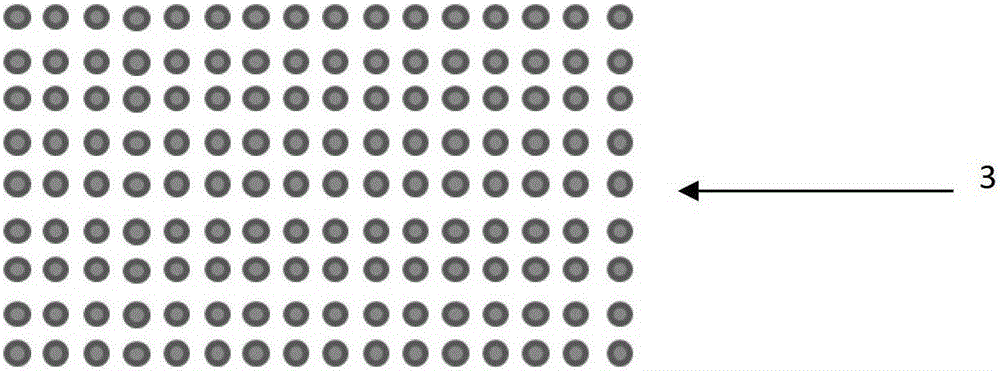

[0047] 3D TiO 2 Preparation of nanomesh materials:

[0048] (1) 0.1 g of commercial titanium dioxide (P25, manufacturer Degussa, about 30 nanometers) was added to 60 mL of sodium hydroxide solution with a concentration of 10 mol / L;

[0049] (2) After magnetic stirring for 5 minutes, transfer the mixed solution to a 100mL hydrothermal kettle

[0050] (3) Put the sealed hydrothermal kettle into the oven, heat the oven to 150°C, start timing, and count 90 minutes, turn off the oven, and cool down to room temperature naturally.

[0051] (4) Turn on the hydrothermal kettle, pour out the reactants and perform centrifugation at a speed of 10,000 rpm. Wash with dilute hydrochloric acid and deionized water with a concentration of 0.2 mol / L and then centrifuge, each repeated 3 times.

[0052] (5) Put the final centrifuged product into a vacuum oven at 60°C, dry it for 8 hours and take it out.

[0053] (6) Put the dried powder into a muffle furnace for sintering, the sintering temper...

Embodiment 3

[0055] 3D TiO 2 Preparation of nanomesh materials:

[0056] (1) Add 0.1g commercial titanium dioxide (P25, manufacturer Degussa) to 60mL sodium hydroxide solution with a concentration of 10mol / L

[0057] (2) After magnetic stirring for 20 minutes, transfer the mixed solution to a 100mL hydrothermal kettle

[0058] (3) Put the sealed hydrothermal kettle into the oven, heat the oven to 150°C, start timing, and count 120 minutes, turn off the oven, and cool down to room temperature naturally.

[0059] (4) Turn on the hydrothermal kettle, pour out the reactants and perform centrifugation at a speed of 15,000 rpm. Use dilute hydrochloric acid with a concentration of 0.2 mol / L and deionized water successively, wash-centrifuge, and repeat 3 times each.

[0060] (5) Put the final centrifuged product into a vacuum oven at 60°C, dry it for 10 hours and take it out.

[0061] (6) Put the dried powder into a muffle furnace for sintering, the sintering temperature is 450°C, the heating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com