Photovoltaic device and preparation deice therefor

A technology of photovoltaic devices and photovoltaic cells, applied in photovoltaic power generation, semiconductor devices, electrical components, etc., can solve problems such as reduced conversion efficiency, leakage, and increase in parallel conductance, so as to increase parallel resistance, increase conversion efficiency, and prevent leakage problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

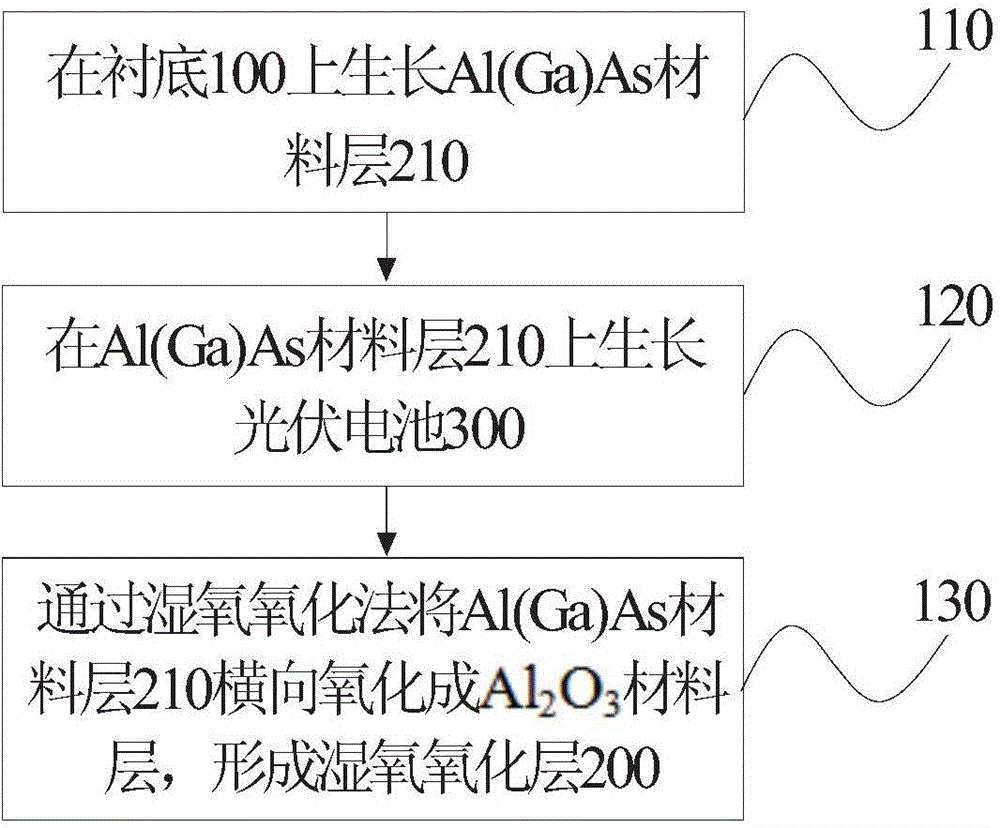

[0030] Steps for growing a single laser photovoltaic cell by metal-organic chemical vapor deposition or molecular beam epitaxy figure 1 ,Specific steps are as follows:

[0031] In step 110 , an Al(Ga)As material layer 210 is grown on the substrate 100 . Specifically, a semi-insulating GaAs substrate 100 is used as a substrate for homogeneous growth of GaAs materials, and its thickness is 200 μm to 500 μm; then the substrate 100 is placed in a growth chamber of metal organic chemical vapor deposition or molecular beam epitaxy, An Al(Ga)As material layer 210 with a thickness of 200nm-500nm is grown on the substrate 100 .

[0032] Wherein, the Al(Ga)As in the Al(Ga)As material layer is Ga 1-x al x As, where x is not less than 0.5.

[0033]In step 120 , a photovoltaic cell 300 is grown on the layer 210 of Al(Ga)As material.

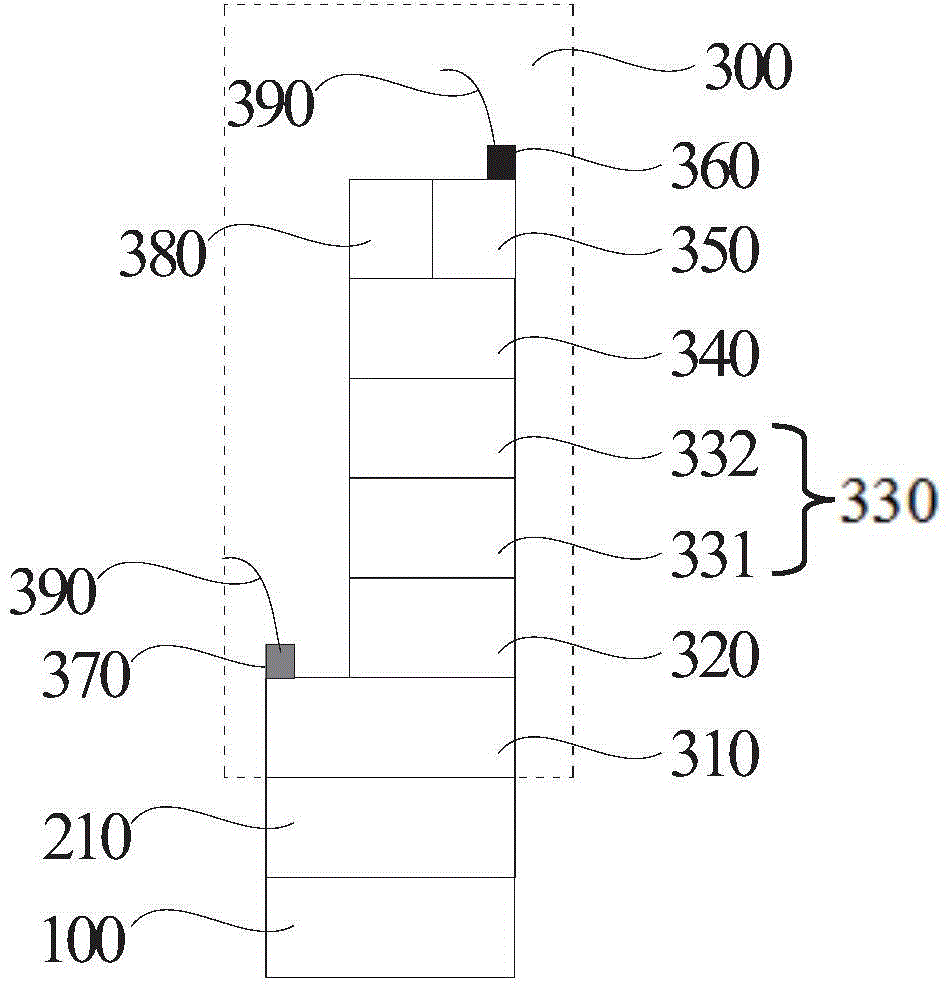

[0034] The specific method is as follows: on the Al(Ga)As material layer 210, N + type contact layer 310, N type back field layer 320, N type base regi...

Embodiment 2

[0045] The laser photovoltaic cell according to the embodiment of the present invention may also be a tandem laser photovoltaic cell, that is, the photovoltaic cell includes several sub-cells connected in series.

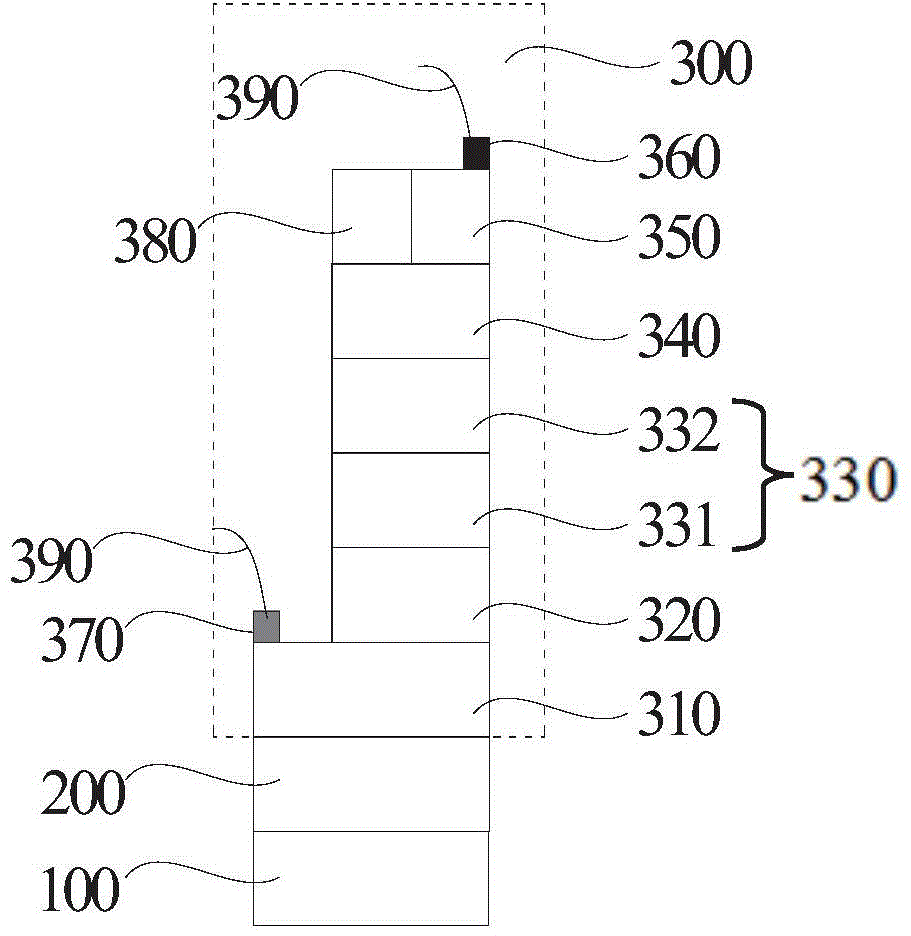

[0046] Figure 4 is a flowchart of a method for preparing a tandem laser photovoltaic cell according to an embodiment of the present invention, Figure 5 is a cross-sectional view of a tandem laser photovoltaic cell before wet oxygen oxidation according to an embodiment of the present invention, Image 6 is a cross-sectional view of a tandem laser photovoltaic cell after wet oxygen oxidation according to an embodiment of the present invention.

[0047] The preparation method of the tandem laser photovoltaic cell according to the embodiment of the present invention refers to Figure 4 Specifically, in the description of embodiment 2, the similarity with embodiment 1 is that steps 210, 220, and 240 are respectively similar to steps 110, 120, and 130, and the specifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com