Compositely laminated ferroelectric-organic hybrid solar cell, and preparation method thereof

A solar cell and composite lamination technology, which is applied in organic semiconductor devices, circuits, photovoltaic power generation, etc., can solve the problems of low carrier mobility, poor battery durability, high volume resistance, etc., to inhibit recombination and improve battery performance. Efficiency, Enhanced Stability Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

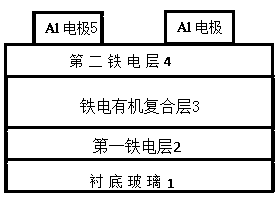

[0040] Such as Figures 1 to 4 It is an embodiment of a nano-inorganic ferroelectric-organic hybrid solar cell and its preparation method, including a bottom-up substrate glass 1, a first ferroelectric layer 2, a ferroelectric-organic composite layer 3, and a second ferroelectric Layer 4 and electrode 5, ferroelectric-organic composite layer 3 is a composite layer of ferroelectric layer and active layer, ferroelectric-organic composite layer 3 is formed by ferroelectric inorganic nano-material BTO and active layer organic polymer material P3HT:PCBM (P3HT:PCBM): composed of BTO sol layer.

[0041] Wherein, the substrate glass 1 is ITO conductive glass, the square resistance of the ITO conductive glass is 20Ω / □, the coverage area is 1.5cm×1.5cm, and the effective coverage area covered by the surface of the ITO conductive glass is 1.0cm×1.5cm; The operating temperature of the substrate glass 1 is 25-200°C.

[0042] In addition, the electrode 5 is a vapor-deposited Al electrode....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com