Polymer solar battery with inverted structure and manufacturing method thereof

A technology of structural polymers and solar cells, which is applied in the field of solar cells, can solve the problems of increasing the cost of battery preparation and the corrosion of self-assembled monolayers, and achieve the goal of realizing commercial large-area production, accelerating the process of industrialization, and increasing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

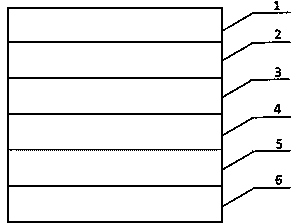

[0023] An inverted structure polymer solar cell, as shown in the accompanying drawings, consists of a glass substrate 1, a tin-doped indium oxide transparent conductive film 2, an electron transport layer 3, an interface modification layer 4, an organic active layer 5 and MoO 3 / Ag composite electrode 6 constitutes a laminated structure in turn, in which the electron transport layer 3 is an aluminum-doped zinc oxide film, the interface modification layer 4 is a polyvinylpyrrolidone film, and the organic active layer 5 is a poly(3-hexylthiophene-fullerene derivative) Film; the doping amount of the aluminum-doped zinc oxide film is 1.0 at%, and the film thickness is 20nm; the thickness of the polyvinylpyrrolidone film is 9 nm; the thickness of the poly3-hexylthiophene-fullerene derivative film is 180nm , the mass ratio of poly-3-hexylthiophene to fullerene derivative film in poly-3-hexylthiophene-fullerene derivative film is 1:0.8; MoO 3 / Ag composite electrode MoO 3 The thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com