Method for preparing macro-quantity hexagonal boron nitride powder through chemical vapor deposition

A chemical vapor deposition, hexagonal boron nitride technology, applied in chemical instruments and methods, inorganic chemistry, nitrogen compounds and other directions, can solve problems such as restricting the development process of boron nitride industrialization, difficulty and other problems, and achieve the promotion of industrialization process, The effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

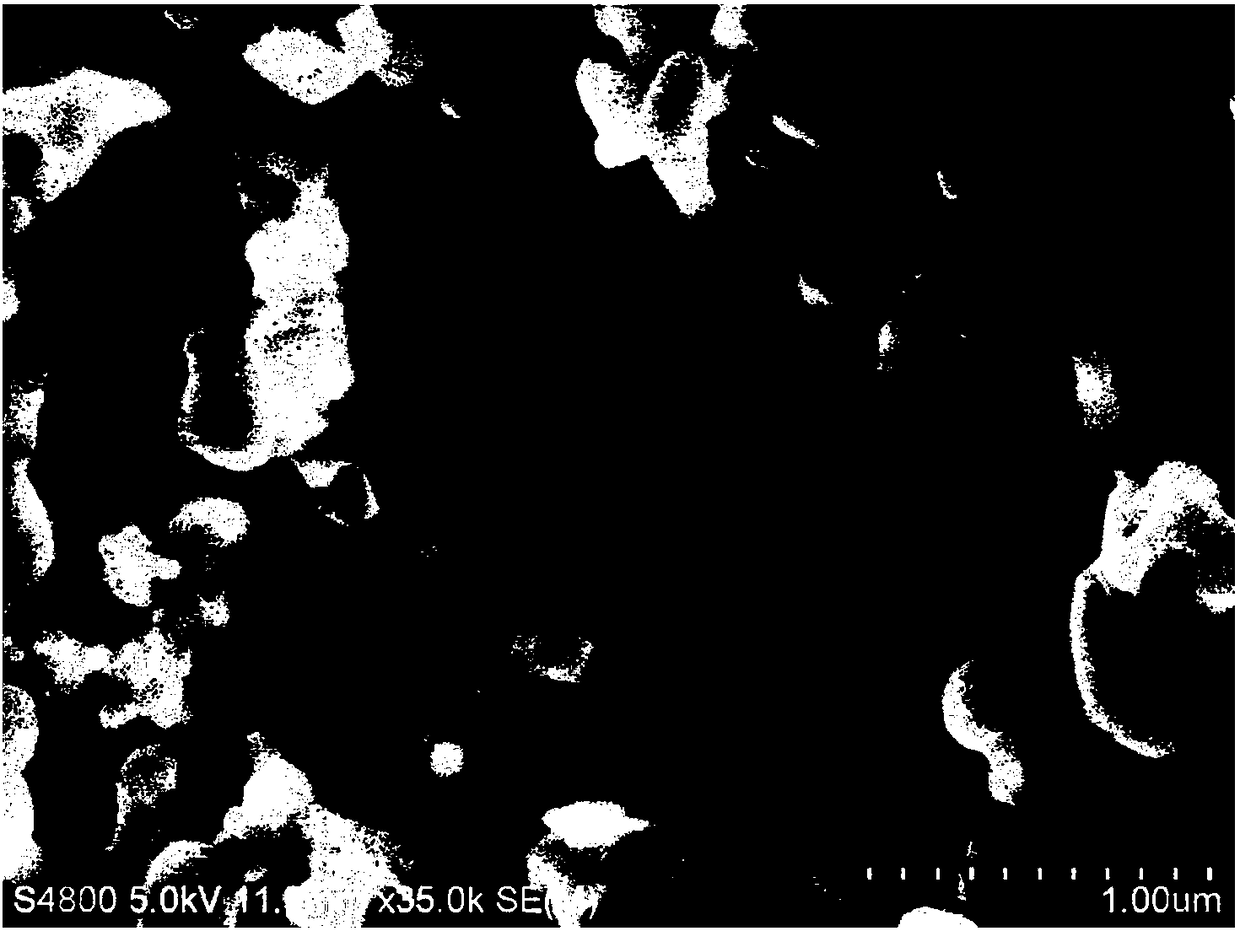

[0059] Example 1: Put B 2 O 3 And MgCl 2 Take 2g B with a molar ratio of 2:3 2 O 3 And 4.1g MgCl 2 Put it in an alumina crucible, then put it in a quartz tube furnace, and pass 200sccm of NH 3 , The temperature is raised to about 1000 ℃, and the NH is closed after the constant temperature reaction at about 1000 ℃ for 180 minutes 3 , Changed to 200sccm of Ar, lowered to room temperature in Ar atmosphere, and taken out to obtain a white macroscopic fluffy crude product. Then, the obtained product is soaked in 2mol / L dilute hydrochloric acid overnight, filtered, and dried to obtain macroscopic fluffy white porous hexagonal boron nitride powder with a purity of more than 99%. figure 1 This is a photograph of the crude product of hexagonal boron nitride prepared in this example. figure 2 This example is a photograph of the post-treated hexagonal boron nitride powder in this example. In this example, a yield of 95% can be obtained. image 3 In the SEM image of the hexagonal boron nitri...

Embodiment 2

[0060] Example 2: Put B 2 O 3 And MgCl 2 Take 2g B with a molar ratio of 2:3 2 O 3 And 4.1g MgCl 2 Put it in an alumina crucible, then put it in an alumina tube furnace, and pass 200sccm of NH 3 , The temperature is raised to about 1450℃, and the NH is turned off after a constant temperature reaction at about 1450℃ for 180 minutes 3 , Changed to 300sccm of Ar, lowered to room temperature in Ar atmosphere, and taken out to obtain a white macroscopic fluffy crude product. Then, the obtained product is soaked in 2mol / L dilute nitric acid overnight, filtered, and dried to obtain macroscopic fluffy white hexagonal boron nitride nanoplate powder with a purity of more than 99%. Image 6 In the SEM image of the hexagonal boron nitride obtained in this example, the high-crystalline boron nitride nanosheets can be seen stacked together. Figure 7 This is the TEM image of the hexagonal boron nitride obtained in this example. Figure 8 The XRD pattern of the hexagonal boron nitride nanosheets...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com