Lead-tin hybrid perovskite thin film, and preparation method and application therefor

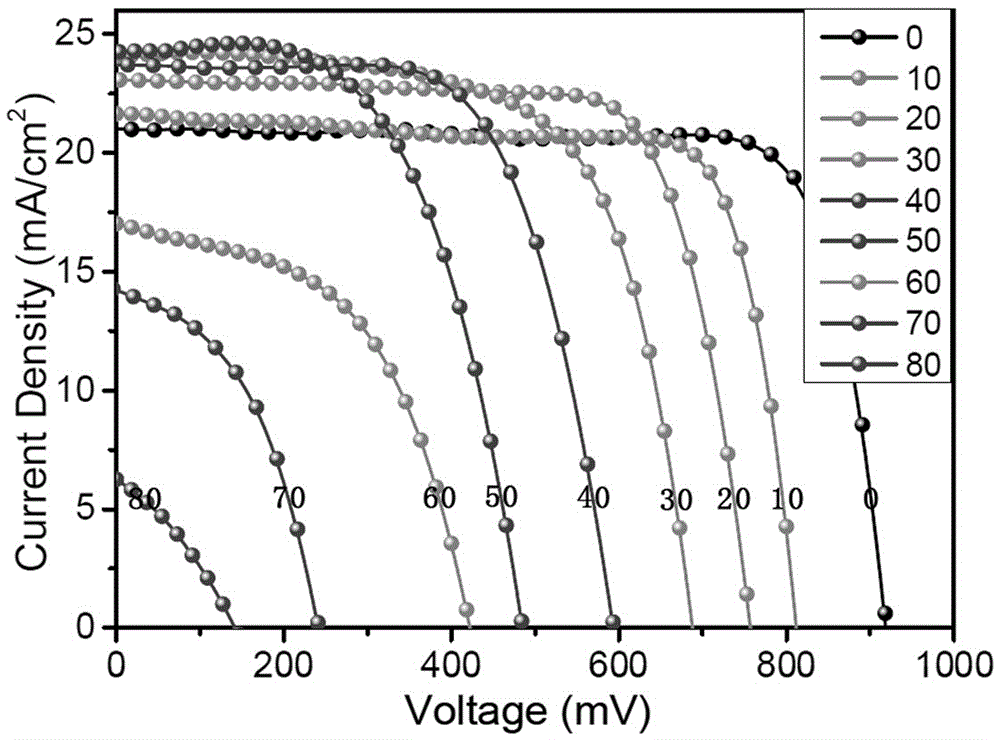

A perovskite and thin film technology, applied in the field of solar cells, can solve the problems of perovskite thin films that are difficult to achieve high coverage, adverse effects on photovoltaic performance, leakage and compound increase, etc., to improve photoelectric conversion efficiency and improve coverage Degree and quality, effect of content reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

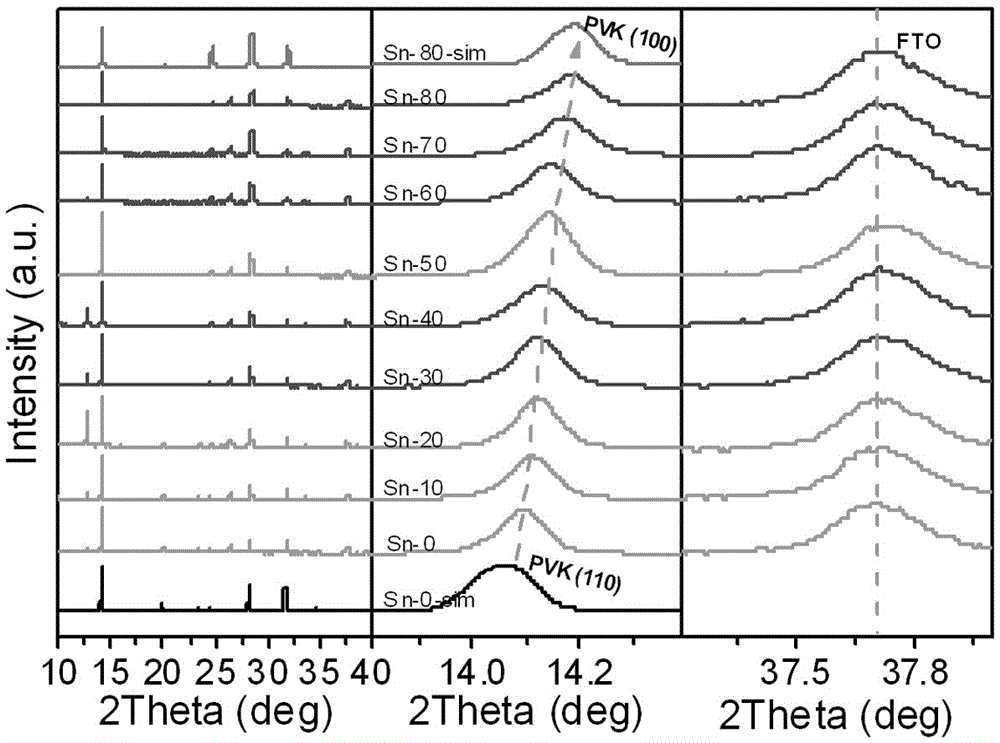

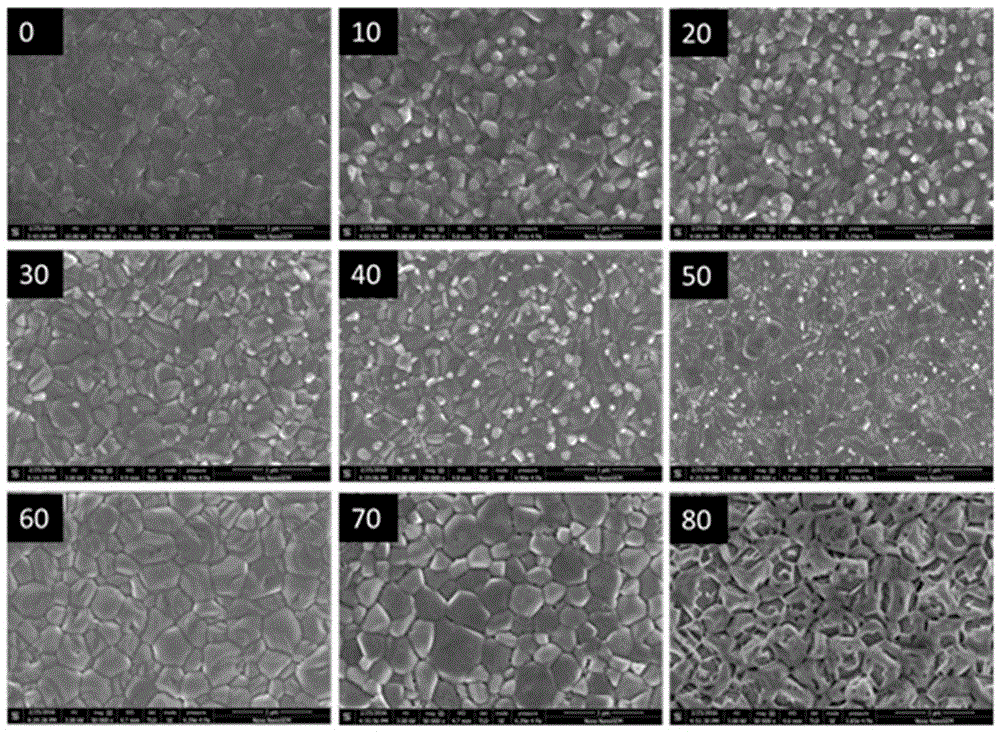

[0026] The preparation method of the lead-tin mixed perovskite film provided by the present invention specifically comprises the following steps:

[0027] a. Weigh PbRE 2 Powder and SnRE 2 Powder; wherein, RE is Cl, Br or I.

[0028] b. Measure dimethylformamide and dimethyl sulfoxide, and mix them to form a mixed solvent, and then divide the formed mixed solvent into two parts.

[0029] c. The weighed PbRE 2 The powder is dissolved in one part of the mixed solvent to form PbRE 2 (DMF+DMSO) solution; the weighed SnRE 2 The powder is dissolved in another mixed solvent to form SnRE 2(DMF+DMSO) solution. When dissolving, the temperature of the solution is controlled between 60°C and 70°C.

[0030] d. Measure PbRE 2 (DMF+DMSO) solution and SnRE 2 (DMF+DMSO) solution, and make the two mix and stir evenly to form a precursor solution, that is: form (PbRE 2 +SnRE 2 ) (DMF+DMSO) solution.

[0031] e. Spin-coat the precursor solution in step d on the substrate at a rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com