Production technology for anti-reflection film of solar cell

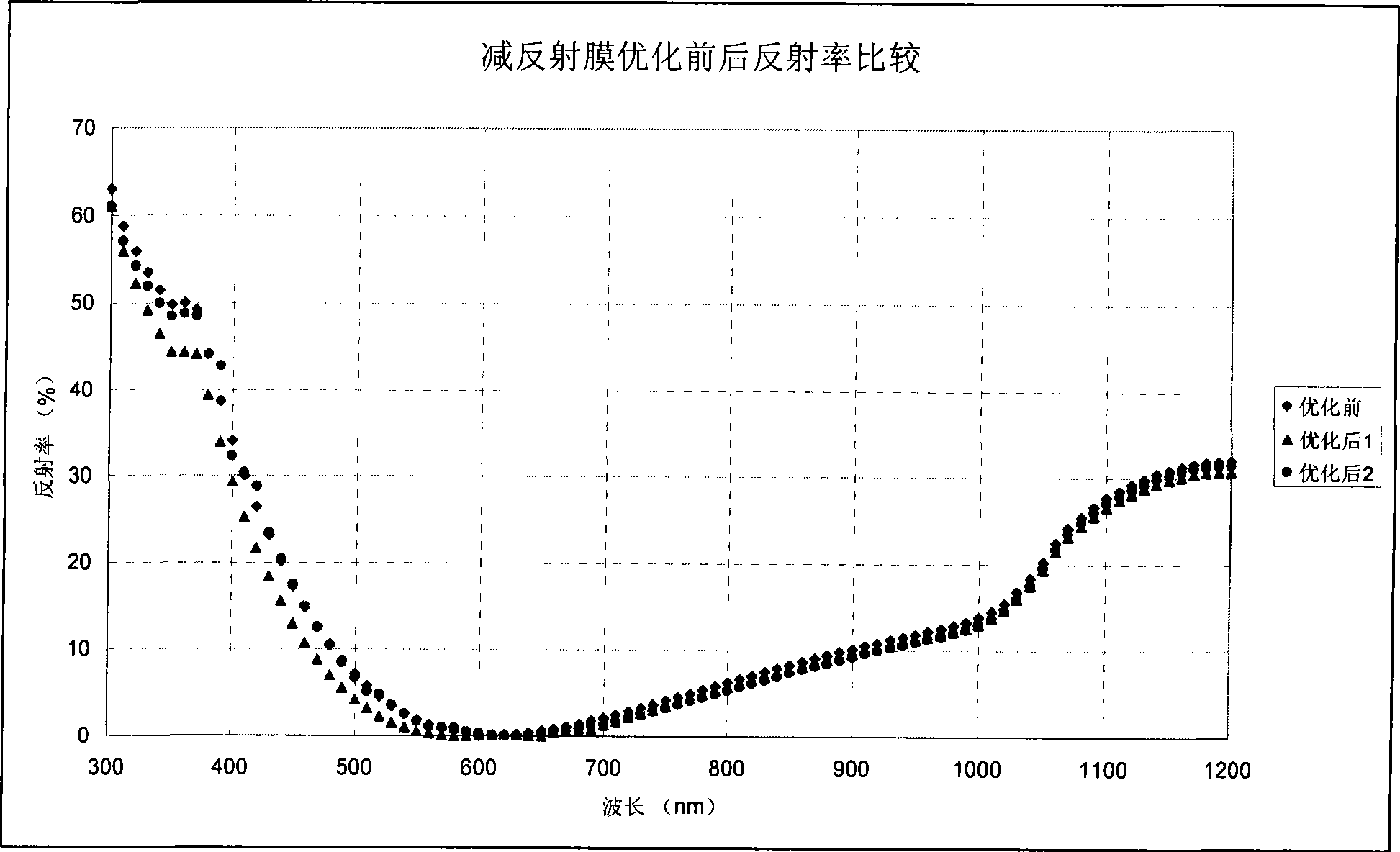

A production process and anti-reflection coating technology, applied in the manufacture of circuits, electrical components, final products, etc., can solve the problems of easy process fluctuations, burn-through, poor blocking ability of harmful impurities, etc., and achieve enhanced high-temperature penetration blocking effect, Effects of reduced radiation damage and wide process temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

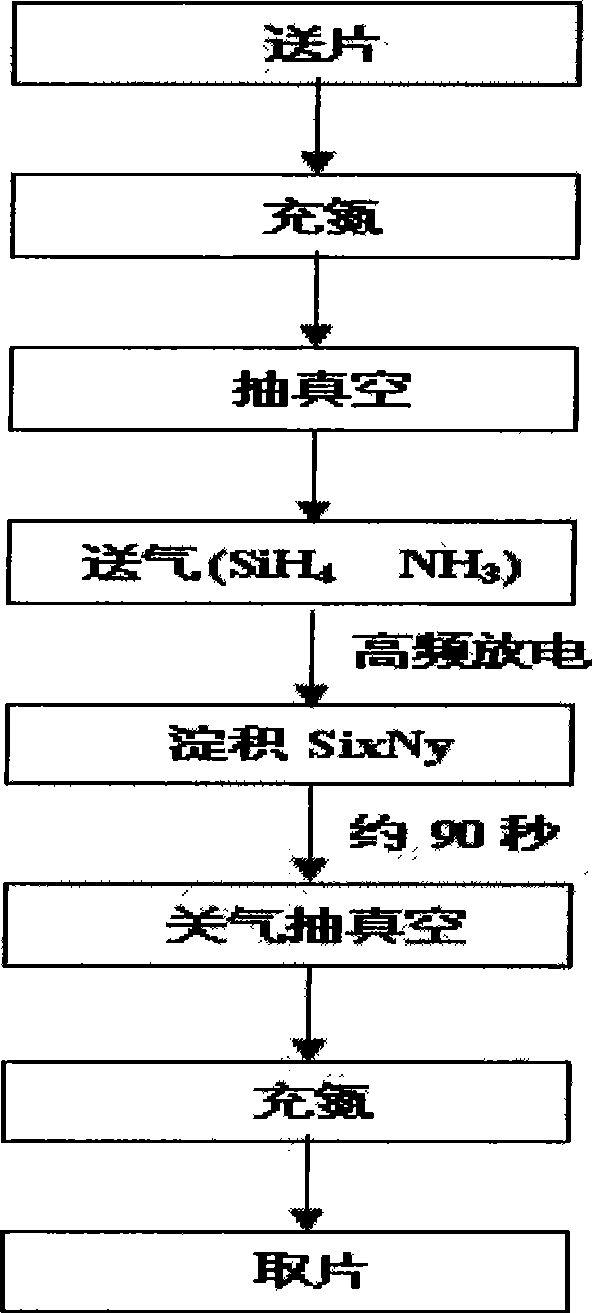

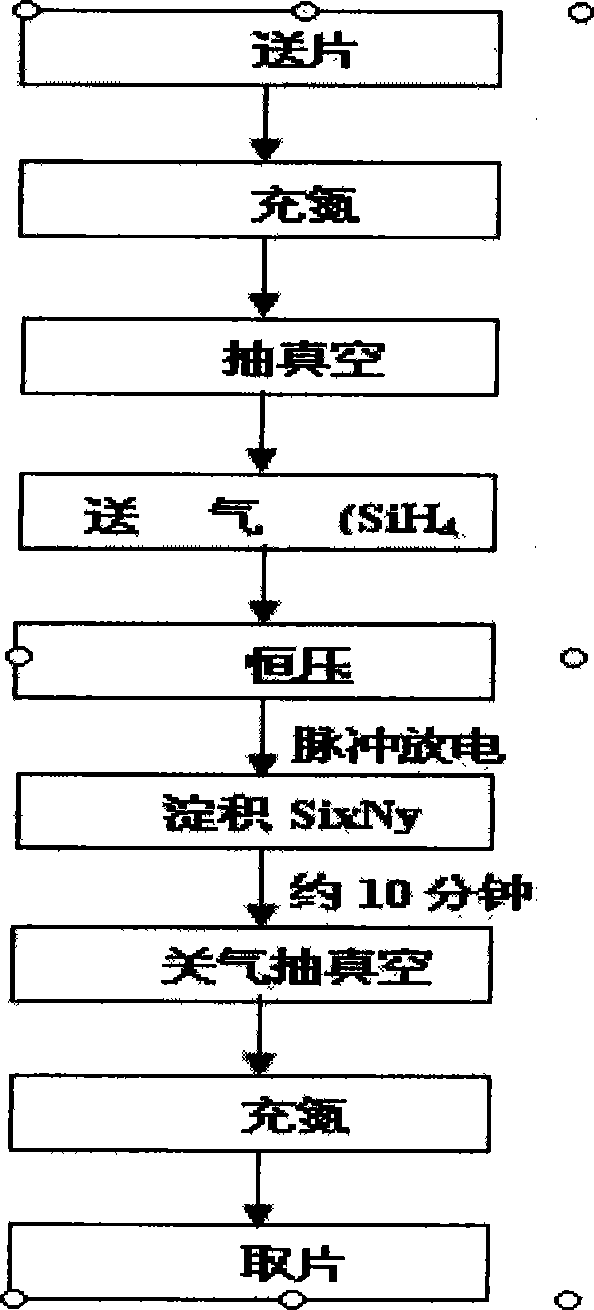

[0016] Such as figure 2 Shown, the concrete production technological process of the present invention is as follows:

[0017] 1. Clean single crystal silicon wafer: clean the silicon wafer that has been diffused to form a PN junction and has been cleaned by plasma edge removal and PSG (phosphosilicate glass) to keep the surface of the silicon wafer dry and free of water stains;

[0018] 2. Inserting the wafer: put the clean and dry silicon wafer N + The layer is vertically inserted into the carrier graphite boat (note that the whole boat must be filled, if it is insufficient, it must be replaced with a companion piece), and then sent into the reaction chamber at a speed of 600mm / min;

[0019] 3. Constant temperature: the boat is sent into the reaction chamber. The ambient temperature in the reaction chamber is 480°C. Due to the influence of the cold end effect, the temperature will drop by 60°C. In order to ensure that the film density in the entire reaction chamber is unifo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com