Method for preparing single crystal silicon velvet surface

A monocrystalline silicon wafer and silicon wool technology, which is applied in the field of preparing monocrystalline silicon wool, can solve the problems of silicon wafer mechanical performance degradation, component power reduction, large leakage current, etc., and achieve the effect of increasing parallel resistance and reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

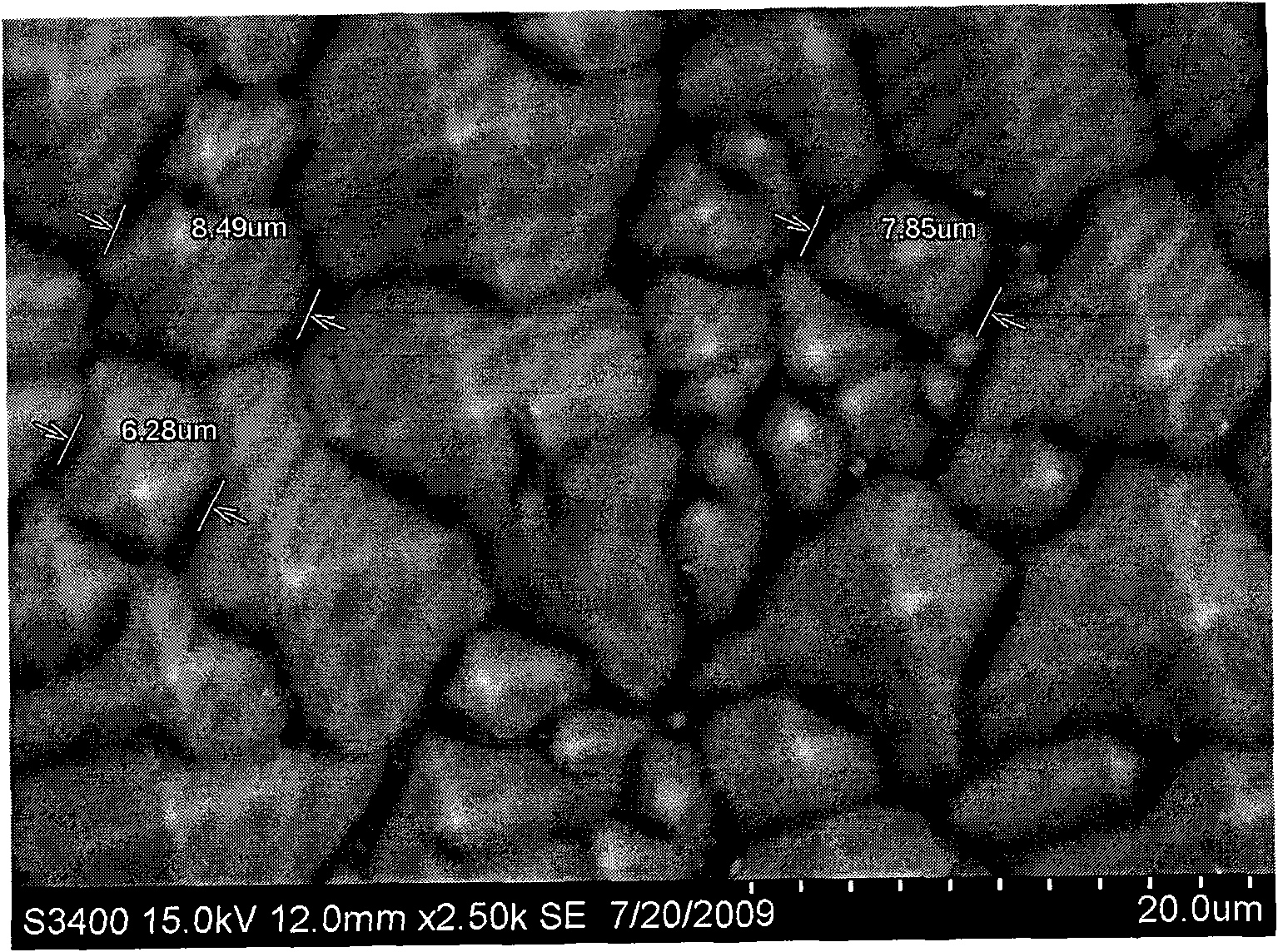

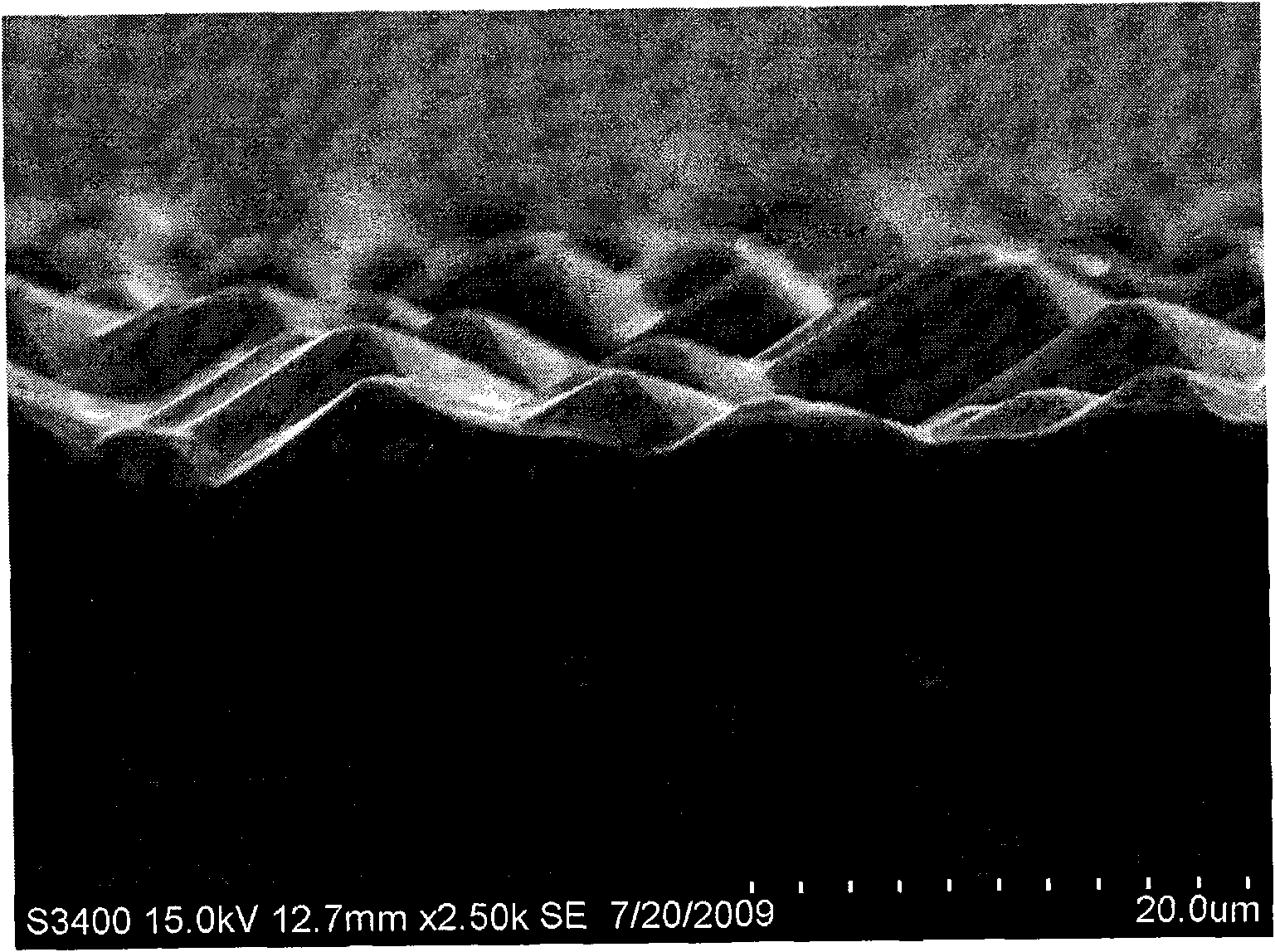

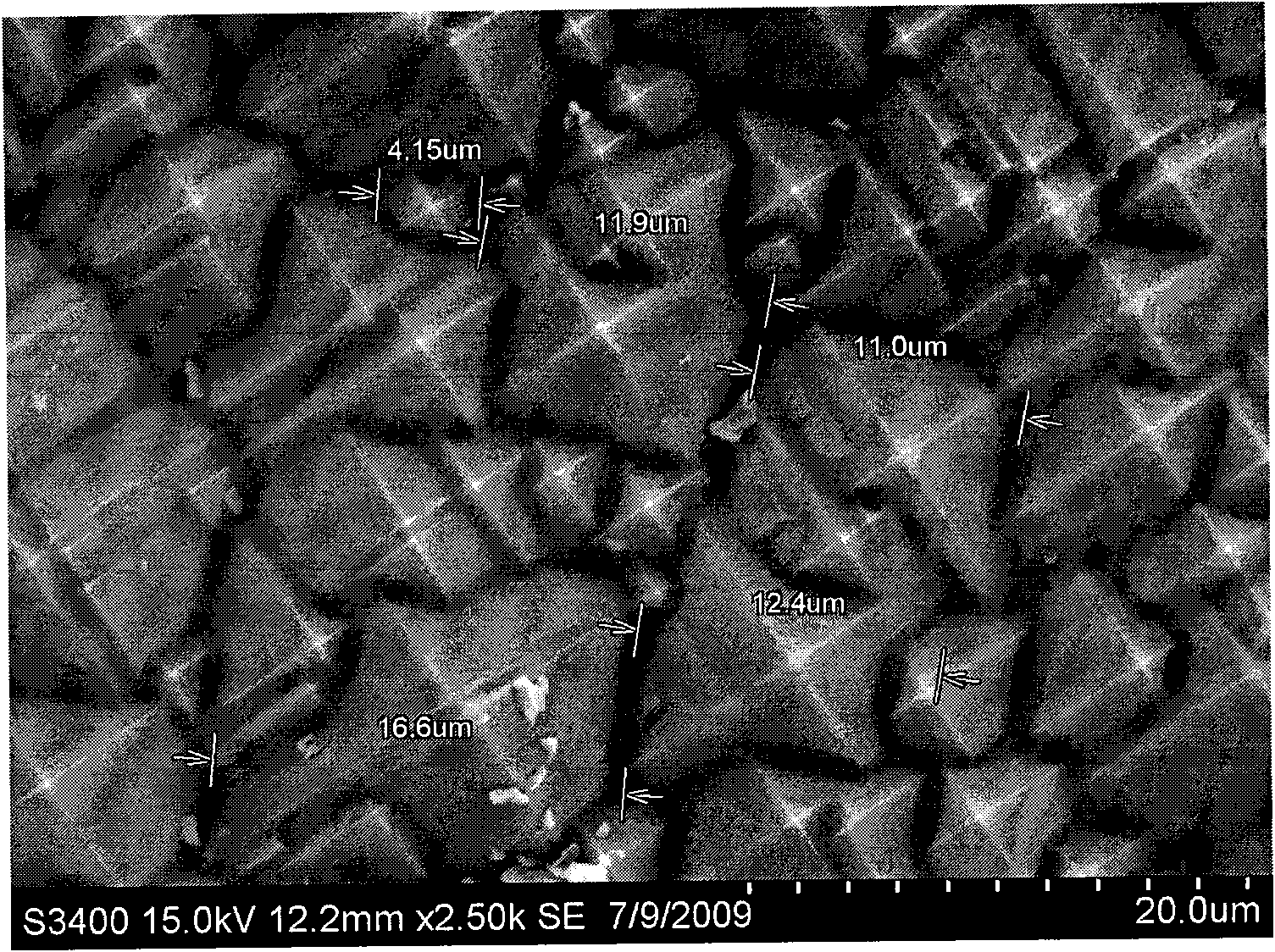

[0025] A method for preparing a monocrystalline silicon suede surface, the monocrystalline silicon chip with a thickness of 4.5 to 25 microns (eg 5 microns, 15 microns, 25 microns) is soaked and etched with an alkali etching solution, and then soaked and etched with an acid etching solution Make monocrystalline silicon suede; Described alkali etching solution is the mixed liquor of sodium hydroxide, sodium silicate, Virahol and water, and wherein the concentration scope of sodium hydroxide is 0.1 to 0.5 mol / liter (example 0.1 mol / liter , 0.3 mol / L, 0.5 mol / L), the concentration range of sodium silicate is 0.01 to 0.07 mol / L (eg 0.01 mol / L, 0.05 mol / L, 0.07 mol / L), the concentration range of isopropanol is 0.7 to 2.0 mol / liter (eg 0.7 mol / liter, 1.3 mol / liter, 2 mol / liter); the acid corrosion solution is a mixture of hydrofluoric acid, nitric acid and water, wherein the concentration of hydrofluoric acid ranges from 1 to 10 Mole / liter (example 1 mole / liter, 5 mole / liter, 10 mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com