A method for preparing amorphous silicon carbide ceramics-diamond composite coating

A silicon carbide ceramic and composite coating technology, applied in metal material coating process, coating, gaseous chemical plating and other directions, can solve the problems of increased time cost, complex process, long preparation process, etc., and achieve friction and wear performance. Improved, high quality, reduced surface roughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

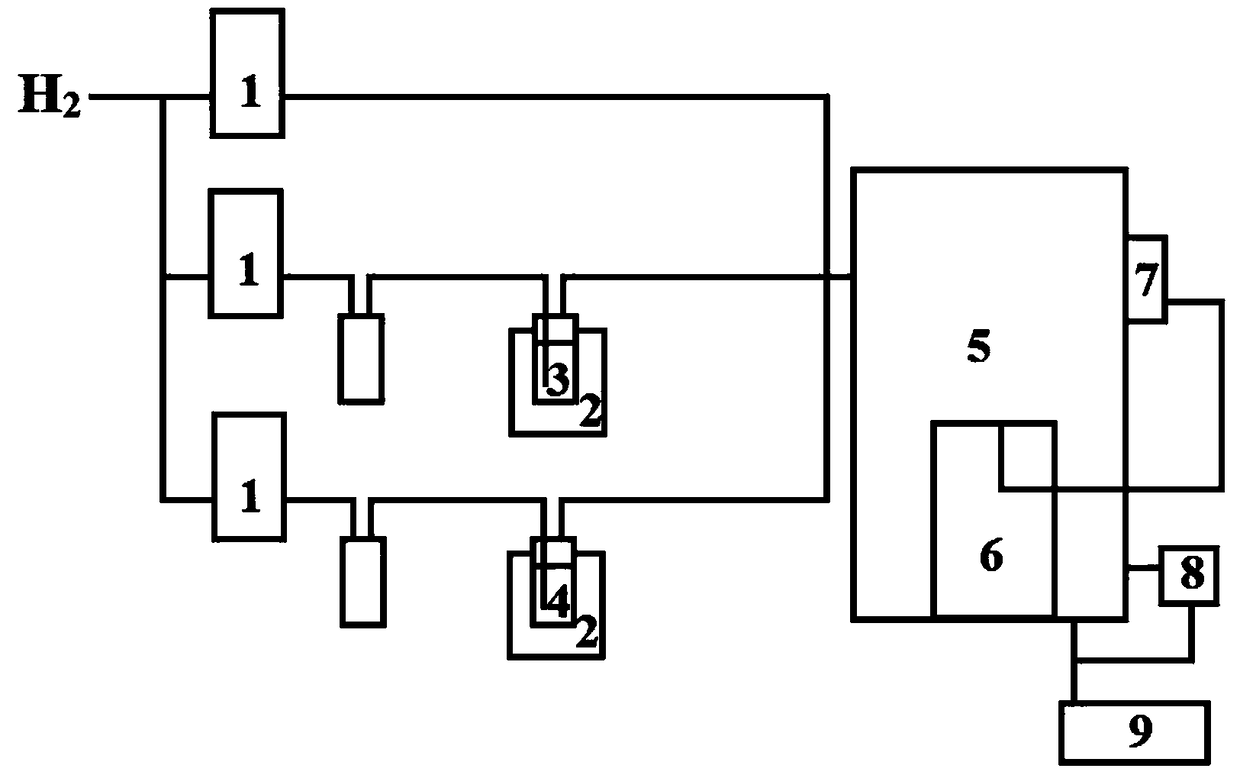

[0030] The preparation method of amorphous silicon carbide ceramics-diamond composite coating of the present invention comprises the steps:

[0031] In the first step, the silicon source is placed in a sealed silicon source bubbling bottle 3, and the silicon source bubbling bottle 3 is placed in the thermostat 2, and the silicon source is bubbled and evaporated by carrying hydrogen gas, and the hydrogen gas with the silicon source vapor After fully mixing with the hydrogen in the hydrogen gas path, it enters the vacuum chamber 5, and deposits an amorphous silicon carbide ceramic film on the surface of the hard alloy substrate by cracking the macromolecular organosilane precursor;

[0032] In the second step, the carbon source is placed in the carbon source bubbling bottle 4, the carbon source bubbling bottle is placed in the thermostat 2, the silicon source gas circuit is closed, the carbon source gas circuit is opened, and the carbon source is bubbled by carrying hydrogen gas ...

Embodiment 1

[0034] The substrate is a YG6 cemented carbide flat piece, with an external dimension of 13mm×13mm×3mm. The substrate is soaked in Murakami solution and ultrasonically etched for 15 minutes to roughen the surface of the substrate. The Murakami solution consists of potassium hydroxide (KOH), iron Potassium cyanide (K 3 (Fe(CN) 6 )) and water (H 2 O), its mass proportion is KOH: K 3 (Fe(CN) 6 ):H 2 O=1:1:10. Then the substrate is soaked in Caro mixed acid solution and etched for 1min to remove the bonded cobalt phase on the surface of the substrate, wherein the composition of Caro mixed acid solution is concentrated sulfuric acid (H 2 SO 4 ) and (H 2 o 2 ), and its volume ratio is H 2 SO 4 :H 2 o 2 =1:10. Then immerse the pretreated cemented carbide substrate in deionized water for ultrasonic cleaning and drying, and place it on the rotary lifting table in the vacuum chamber of the chemical vapor deposition device to deposit the amorphous silicon carbide ceramic-dia...

Embodiment 2

[0044] The substrate is a YG6 cemented carbide turning blade with an external dimension of 13mm×13mm×5mm. The substrate is soaked in Murakami solution and ultrasonically corroded for 15 minutes to roughen the surface of the substrate. The components of Murakami solution are potassium hydroxide (KOH), iron Potassium cyanide (K 3 (Fe(CN) 6 )) and water (H 2 O), its mass proportion is KOH: K 3 (Fe(CN) 6 ):H 2 O=1:1:10. Then the substrate is soaked in Caro mixed acid solution and etched for 1min to remove the bonded cobalt phase on the surface of the substrate, wherein the composition of Caro mixed acid solution is concentrated sulfuric acid (H 2 SO 4 ) and (H 2 o 2 ), and its volume ratio is H 2 SO 4 :H 2 o 2 =1:10. Then immerse the pretreated cemented carbide substrate in deionized water for ultrasonic cleaning and drying, and place it on the rotary lifting table in the vacuum chamber of the chemical vapor deposition device to deposit the amorphous silicon carbide c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com