Split type crucible for crystal growth of silicon carbide

A technology of crystal growth and silicon carbide, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of temperature gradient change, temperature gradient instability, seed crystal sublimation damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

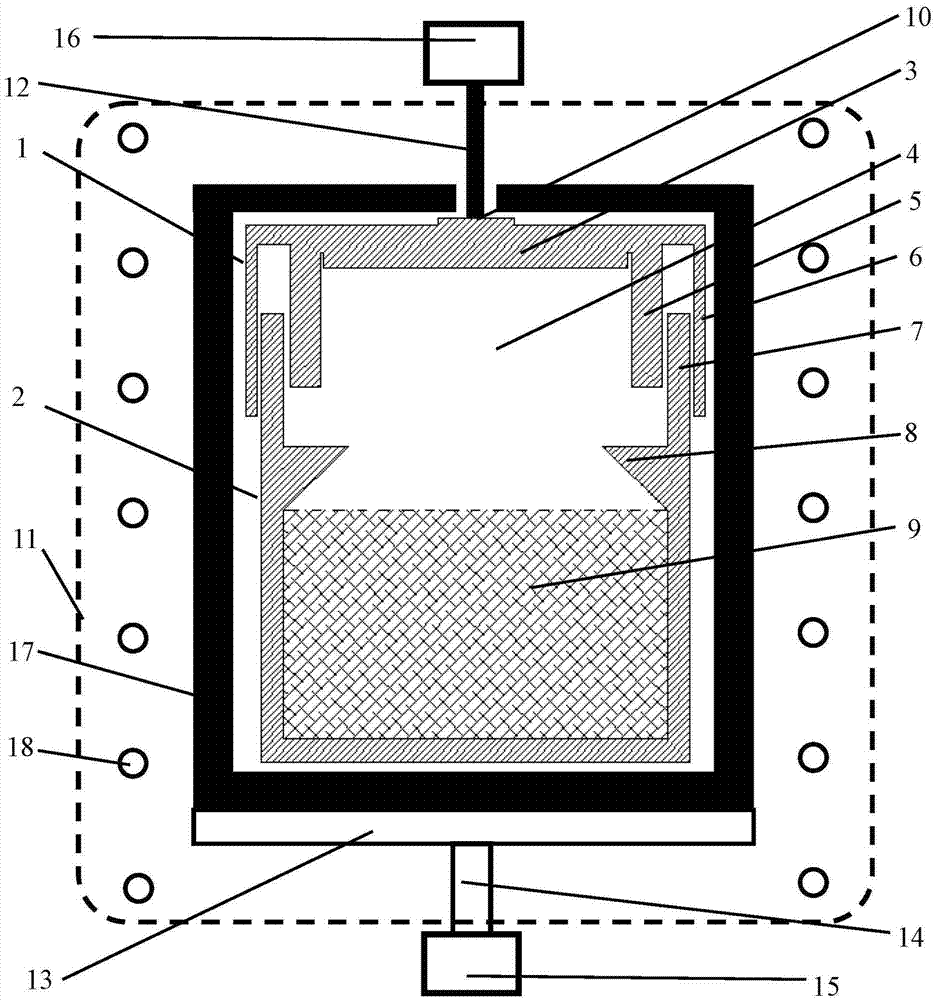

[0081] Using high-purity graphite material (purity>99.9%) to prepare such as figure 1 In the SiC crystal growth crucible with the structure shown, the gap between the adjacent surfaces of the growth chamber 5 , the outer cylinder 6 and the guide cylinder 7 is 0.5 mm. The specific structure is as described above. The crucible with this structure can control the rise and fall of the growth chamber 1 during the crystal growth process, control the position of the seed crystal in the crystal seeding stage in the early growth stage, adjust the distance between the crystal growth surface and the raw material during the growth process, and grow high-quality SiC crystals.

Embodiment 2

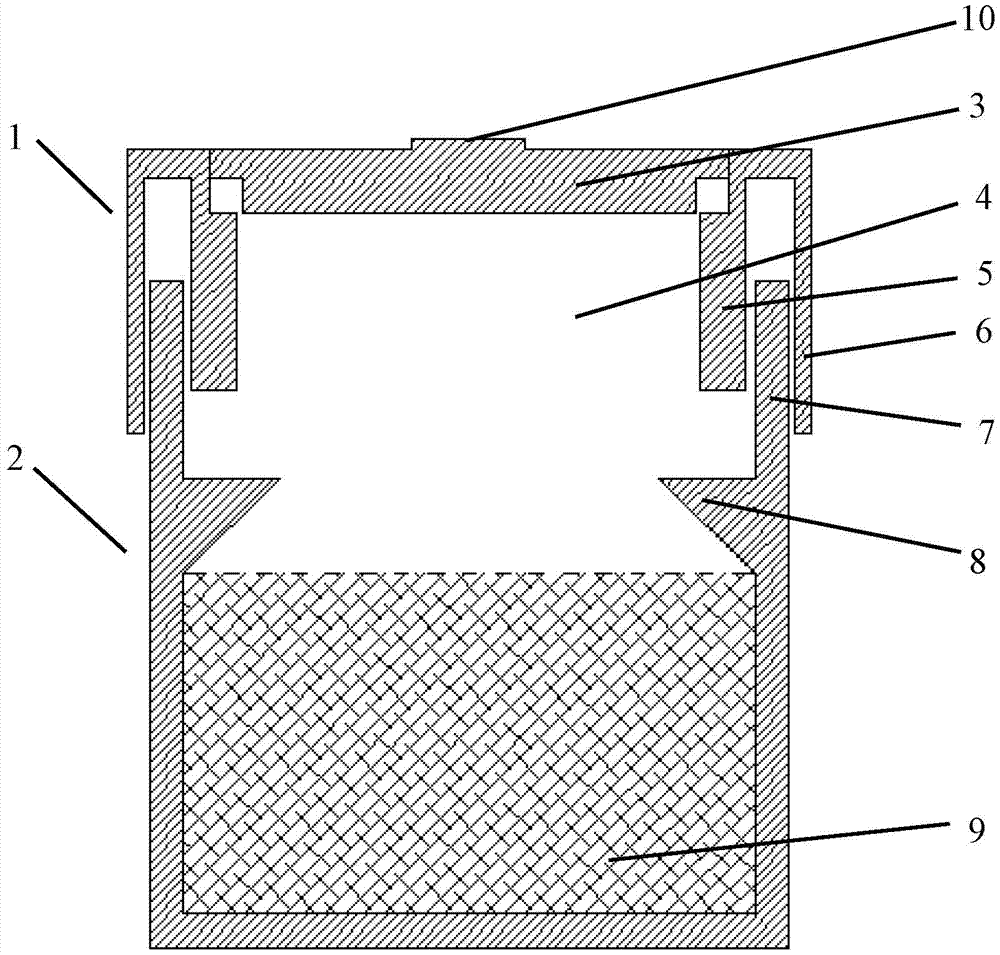

[0083] Using high-purity graphite material (purity>99.9%) to prepare such as figure 2 The crucible for SiC crystal growth with the structure shown, wherein the growth chamber 1 includes a seed crystal holder 3, a growth chamber 4, a growth chamber cylinder 5, and a growth chamber cylinder 6; Sheng raw materials9.

[0084] In this embodiment, there is a cavity structure between the top of the tube 5 in the growth chamber and the seed crystal holder 3, which is a space for the crystallization of redundant gas phase components; at the same time, to realize this design, the growth chamber 1 is composed of a plurality of different components.

[0085] When the growth cavity 1 and the raw material cavity 2 are combined, the growth cavity 1 is set on the guide cylinder 7, and the gap between the two adjacent surfaces is 0.1mm, and the two can slide and rotate relatively freely.

[0086] The top of the growth chamber 1 is provided with a connecting portion connected with correspondi...

Embodiment 3

[0089] Using tantalum (elemental metal) (purity>99.9%) to prepare as figure 1 For the crucible for SiC crystal growth with the structure shown, please refer to the previous description for the specific structure. The gap between the adjacent surfaces of the growth chamber cylinder 5, the outer cylinder 6 and the guide cylinder 7 is 1 mm. The use of tantalum crucibles can prevent the C element in the graphite crucible from becoming part of the C source for SiC crystal growth, which is more conducive to the control of gas phase components, and can also control the rise and fall of the growth chamber 1 during the crystal growth process, and crystal seeding in the early growth stage The stage controls the position of the seed crystal, adjusts the distance between the crystal growth surface and the raw material during the growth process, and finally grows a high-quality SiC crystal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com