Graphene device capable of achieving continuous growth

A technology of graphene and quartz chambers, which is applied in the field of continuous growth graphene devices, can solve the problems of no cooling device, the inability to remove the furnace body, and the inability to realize rapid cooling of graphene materials, etc., achieving short length, compact structure, and solution Effect of Rapid Cooling Problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

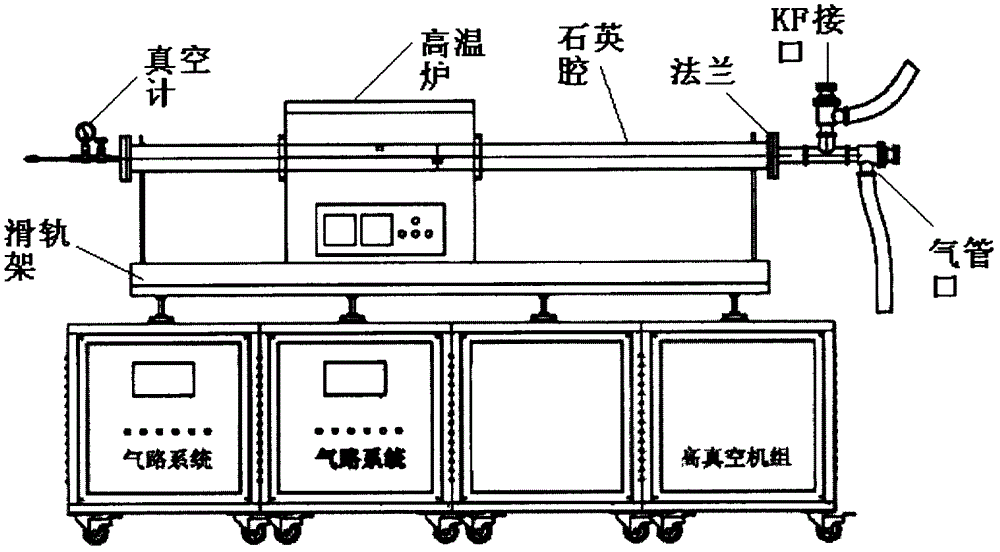

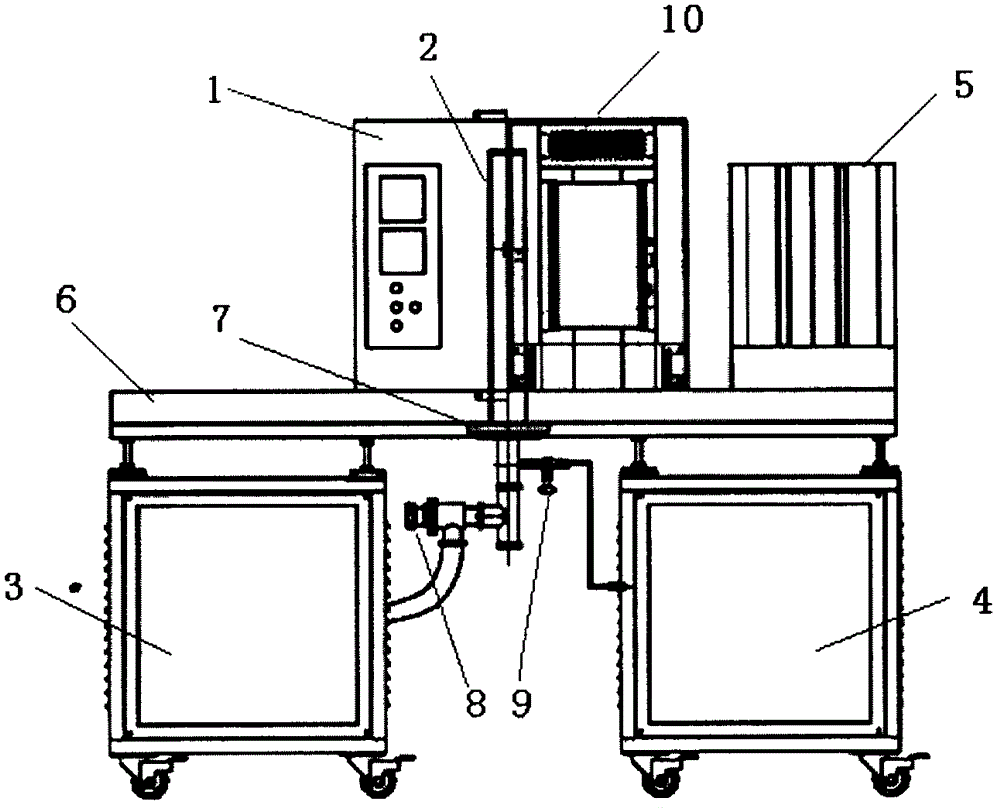

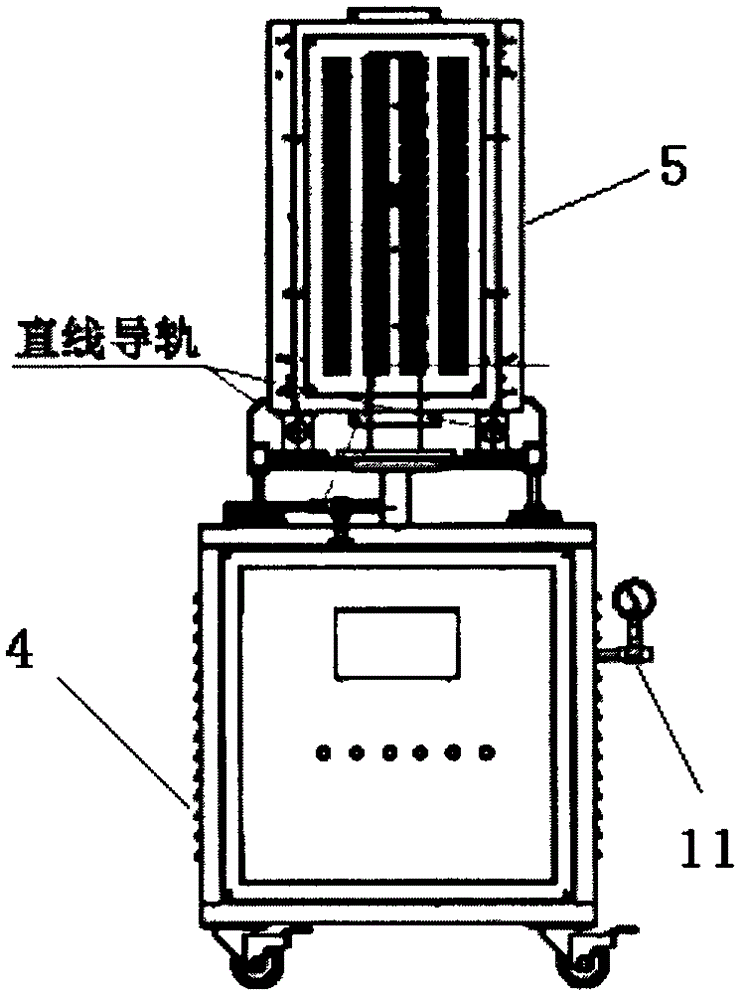

[0015] see figure 2 and image 3 The specific embodiment of the present invention adopts the following technical solutions: it includes a high-temperature furnace 1, a quartz cavity 2, a high vacuum unit 3, a gas path system 4, a liquid nitrogen cooling box 5 and a slide rail frame 6, and the quartz cavity 2 is vertical Fixed on the middle end of the slide rail frame 6; the high temperature furnace 1 and the liquid nitrogen cooling box 5 are respectively installed on the left and right ends of the slide rail frame 6; the high temperature furnace 1 adopts a vertical structure that can be opened in half. When working and using, after the feeding of the furnace tube is completed, the high-temperature furnace 1 moves to the furnace tube through the linear guide rail; the locking flange 7 vacuumizes and cleans the furnace cavity, and at the same time the gas system 4 starts to mix gas; to be cleaned After the furnace chamber is finished, lock the KF baffle valve 8, open the gas i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com