A preparation method of large-scale core-shell structure quantum dots

A core-shell structure and quantum dot technology, which is applied in the field of luminescent quantum dot materials, can solve the problem that the particle size and yield of quantum dots are difficult to maintain at a high level, and achieve the effect of continuous growth and avoidance of influence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

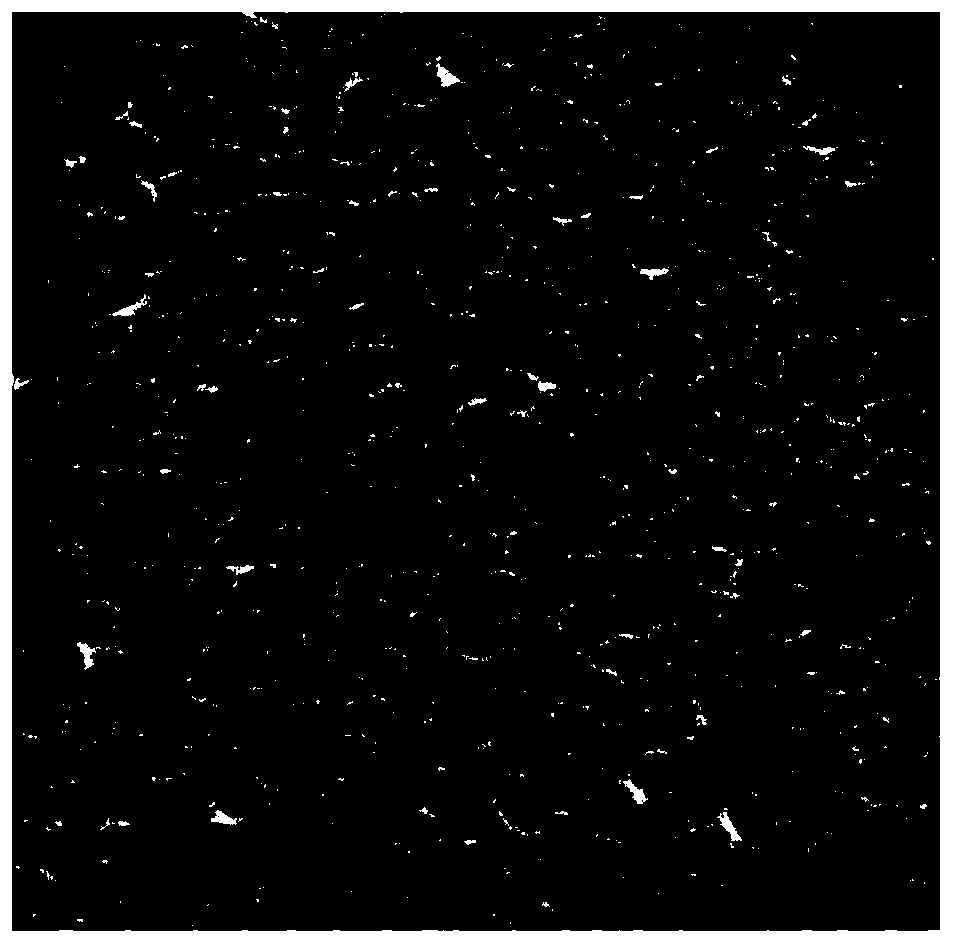

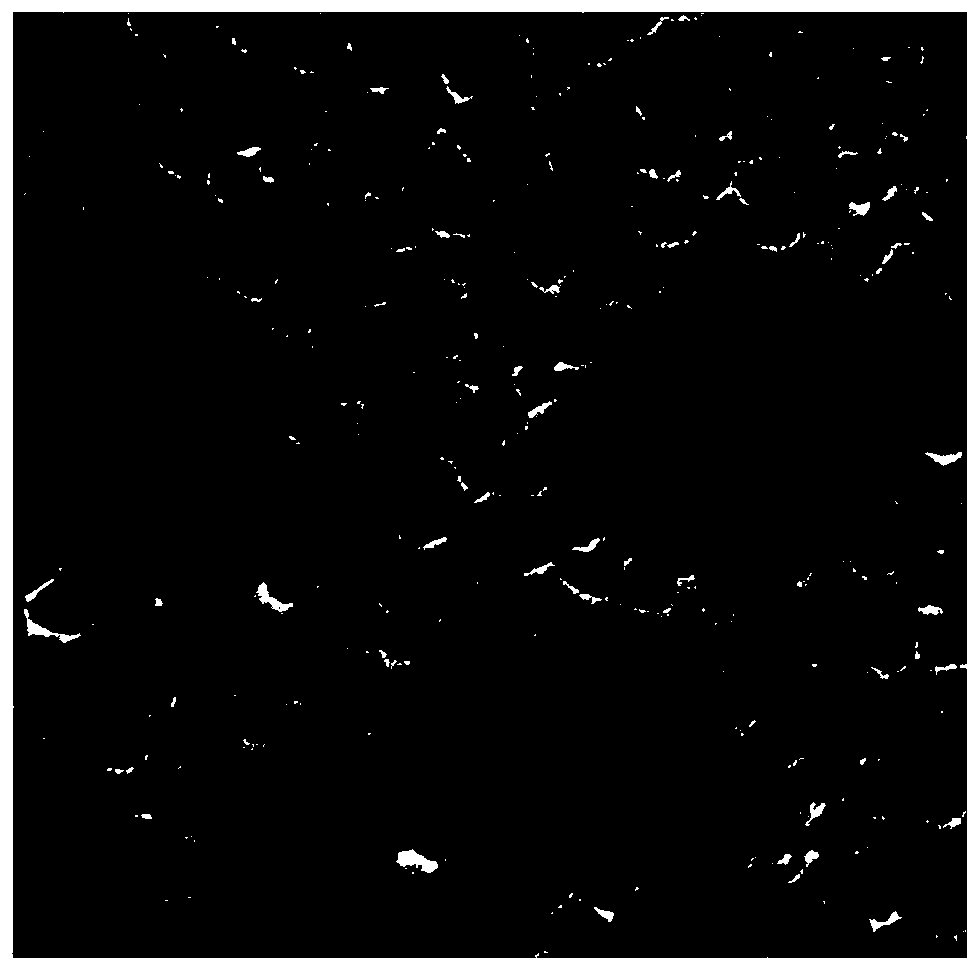

Image

Examples

preparation example Construction

[0026] The invention provides a method for preparing quantum dots with a large-scale core-shell structure, comprising the following steps:

[0027] Under a protective atmosphere, the dispersion liquid of the shell layer source is added dropwise to the core body dispersion liquid by dropping at intervals, and the core-shell structure quantum dots are obtained through in-situ growth.

[0028] In the present invention, the protective atmosphere is preferably nitrogen, and the present invention has no special requirements on the specific way of providing the protective atmosphere, and a method well known to those skilled in the art can be used.

[0029] In the present invention, the dropwise addition of the dispersion liquid of the same kind of shell source is continuous dripping. When replacing the dispersion liquid of different seed shell sources, a certain time interval is required so that the previous shell source can fully grow. In the present invention, the interval time is ...

Embodiment 1

[0068] Take 6×10 -7 mmol, CdSe quantum dots with a particle size of 2.7nm were added to the mixed dispersion of 6mL octadecene and 6mL oleylamine, and the temperature was raised to 300°C at a rate of 8°C / min under nitrogen protection, and oil was added dropwise to the nucleus dispersion. Octadecene dispersion of cadmium oleate and sulfur powder, the total volume is 30mL, the concentration of cadmium oleate in the dispersion is 0.08mmol / mL, the molar ratio of cadmium in cadmium oleate to sulfur powder is 1:1, zinc oleate Calculated by zinc ions; the dropping rate is 6mL / h, after the dropping reaction is completed, CdSe / CdS core-shell structure quantum dots are obtained, and the number of shell layers is 7 layers; grow in situ for 15min, then drop zinc oleate and oleic acid into the dispersion The mixture of cadmium and octaalkylmercaptan is 60mL, the concentrations of zinc oleate and cadmium oleate are both 0.1mmol / mL, the ratio of zinc oleate and cadmium oleate is 1:1, and the...

Embodiment 2

[0070] Take 5×10 -7 mmol, CdSe quantum dots with a particle size of 3.1nm, added to the mixed dispersion of 6mL octadecene and 3g octadecylamine, heated to 280°C at a rate of 10°C / min under the protection of nitrogen, and dropped into the nucleus dispersion Octadecene dispersion of zinc oleate and sulfur powder, the total volume is 15mL, the concentration of cadmium oleate in the dispersion is 0.1mmol / mL, the molar ratio of cadmium in oleate cadmium to sulfur powder is 1:1, oleic acid Zinc is calculated as zinc ion; the dropping rate is 6mL / h, after the dropping reaction is completed, CdSe / ZnS core-shell structure quantum dots are obtained, and the number of shell layers is 4 layers; the in-situ growth is 10min; then zinc oleate, oil The mixture of cadmium oleate and cadmium oleate is 80mL, the concentrations of zinc oleate and cadmium oleate are both 0.1mmol / mL, the ratio of zinc oleate and cadmium oleate is 1:1, and oleic acid cadmium is oleic acid 1.2 times the molar sum o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com