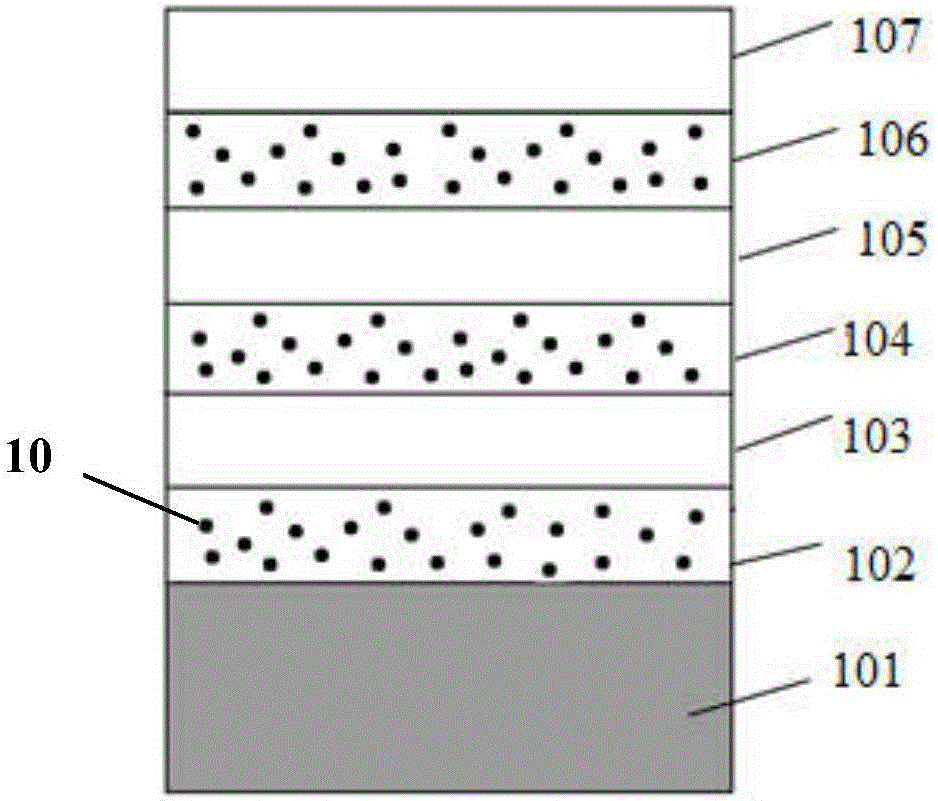

Tool provided with diamond/silicon carbide composite coating and preparation method thereof

A technology of diamond coating and composite coating, which is applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of poor fracture toughness, insufficient adhesion between diamond coating and tool substrate, and achieve The effect of resisting shear stress, reducing thermal stress and increasing bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing a tool with a diamond / silicon carbide composite coating, comprising the following steps:

[0041] (1) With the YG8 (WC-8% Co) cemented carbide end mill sold on the domestic market as the tool substrate, it is carried out sandblasting pretreatment, injection pressure 200kPa, silicon carbide sand particle size 300 orders, then respectively in acetone Ultrasonic cleaning the cemented carbide substrate with alcohol for 15 minutes to obtain the cleaned substrate;

[0042] Put the above matrix in H 2 SO 4 :H 2 o 2 = Immerse in a solution of 1:10 (volume ratio) for 1 minute, chemically etch cobalt, wash and dry, and then in the alcohol suspension containing diamond nanopowder, sonicate the surface of the tool substrate for 30 minutes to inoculate Diamond pre-nucleation, cleaning with alcohol after taking it out, and finally blowing dry with nitrogen to obtain the inoculated matrix;

[0043] (2) Put the cemented carbide substrate after the inoculatio...

Embodiment 2

[0048] A method for preparing a tool with a diamond / silicon carbide composite coating, comprising the following steps:

[0049] (1) With the YG6X (WC-6% Co) cemented carbide micro-drill bit sold on the domestic market as the tool substrate, it is carried out sandblasting pretreatment, injection pressure 200kPa, silicon carbide sand particle size 300 orders, then respectively in acetone and Ultrasonic cleaning of the cemented carbide substrate in alcohol for 15 minutes to obtain the cleaned substrate;

[0050] Place the above-mentioned cleaned substrate in an alcohol suspension containing diamond nanopowder, ultrasonicate the surface of the tool substrate for 30 minutes to inoculate the diamond pre-nucleation, take it out, wash it with alcohol, and dry it with nitrogen to obtain the inoculated diamond. matrix;

[0051] (2) Put the inoculated cemented carbide substrate into the vacuum chamber of the hot wire chemical vapor deposition equipment, and use the hot wire chemical vap...

Embodiment 3

[0055] A method for preparing a tool with a diamond / silicon carbide composite coating, comprising the following steps:

[0056] (1) Si sold on the domestic market 3 N 4 The milling blade is used as the tool substrate, and it is subjected to sandblasting pretreatment, the injection pressure is 200kPa, the silicon carbide sand particle size is 300 mesh, and then the cemented carbide substrate is ultrasonically cleaned in acetone and alcohol for 15 minutes to obtain the cleaned substrate;

[0057] Put the above-mentioned cleaned substrate in the diamond suspension and ultrasonically for 20 minutes, take it out, wash it with alcohol, and dry it with nitrogen to obtain the substrate after inoculation treatment;

[0058] (2) Put the inoculated cemented carbide substrate into the vacuum chamber of the hot wire chemical vapor deposition equipment, and use the hot wire chemical vapor deposition method to deposit the silicon carbide / diamond composite coating. Introduce hydrogen into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com