A kind of two-dimensional transition metal chalcogenide film and its preparation method and application

A technology of transition metals and chalcogenides, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve problems such as the inability to achieve continuous growth of single-layer two-dimensional semiconductor nano-films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

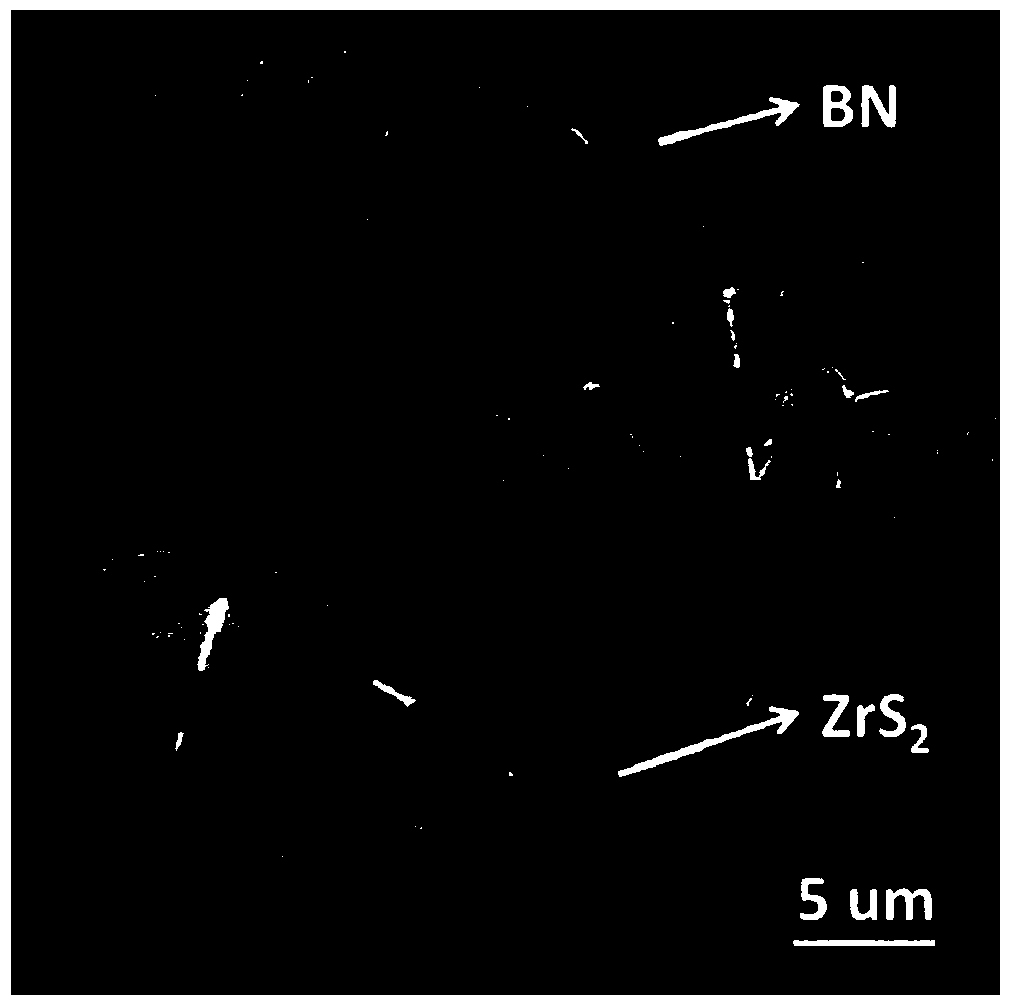

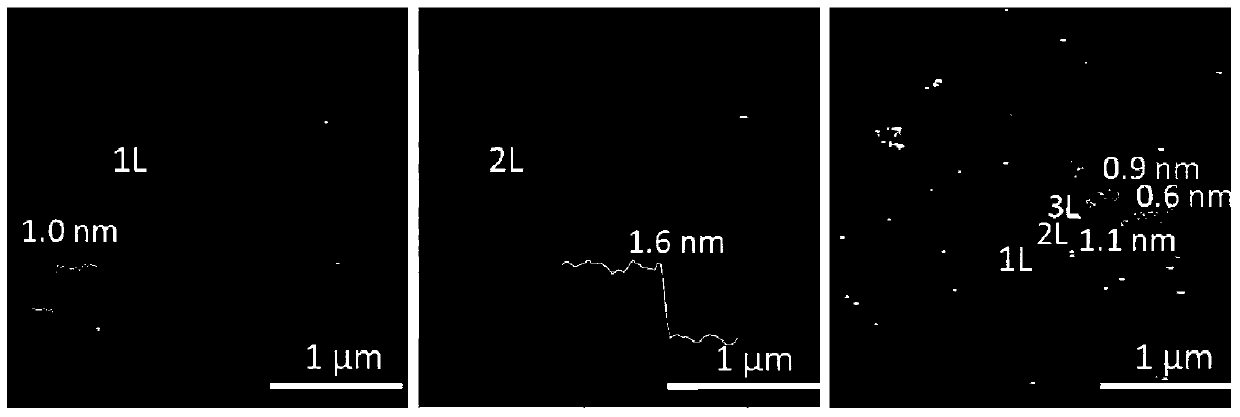

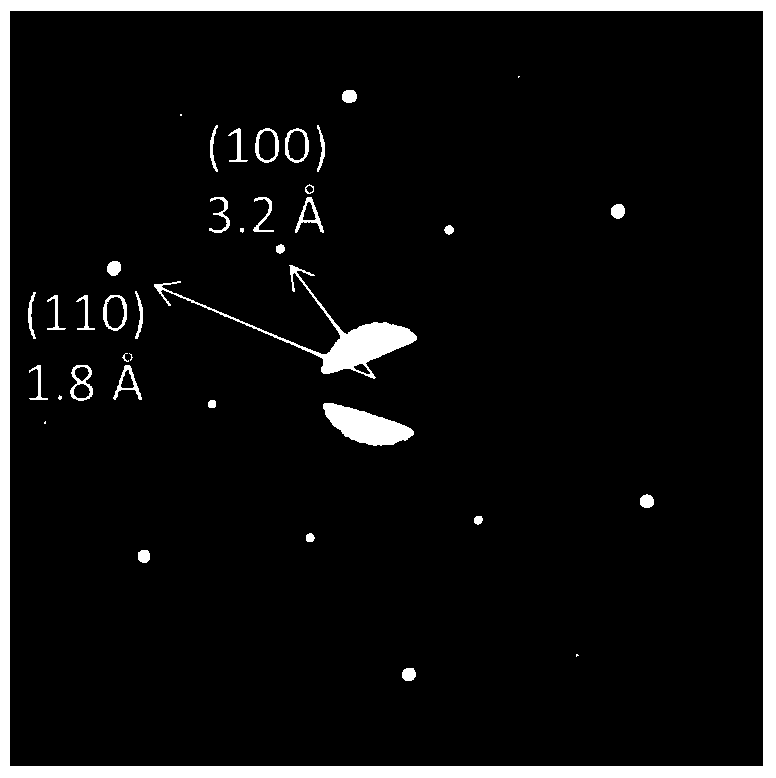

[0067] One adopts chemical vapor deposition device to prepare single-layer or few-layer ZrS 2 , ZrSe 2 , HfS 2 or HfSe 2 The chemical vapor deposition device is a device known in the art, and the chemical vapor deposition device used in this embodiment includes a tubular heating furnace, a heating belt and a quartz tube, wherein the quartz tube is 1.4 m long and 1 inch in diameter, and There are vacuum valves at both ends of the quartz tube, which are used to evacuate the inside of the quartz tube and send protective gas; the quartz tube should be longer than the tubular heating furnace, so that a part of the quartz tube is located outside the tubular furnace to prevent ZrCl 4 / HfCl 4 and S / Se, guaranteed ZrCl 4 / HfCl 4 and S / Se are not affected by the temperature in the heating furnace; the heating furnace is provided with an independent thermocouple in the quartz tube, which is used to heat the corresponding position in the quartz tube; the heating band is composed of t...

Embodiment 2

[0077] A two-dimensional ZrSe prepared by chemical vapor deposition 2 The method, described chemical vapor deposition device is identical with embodiment 1, and the difference of described method and embodiment 1 is:

[0078] The sources described in step (2) are selenium and zirconium chloride, and the heating and volatilization temperatures are 230°C and 170°C respectively, zirconium chloride is placed upstream of the airflow, and selenium is placed downstream of zirconium chloride, as described in step (4). The protective gas is hydrogen only, and the result is two-dimensional zirconium selenide.

[0079] The ZrSe that this embodiment obtains 2 Atomic force microscope picture as Figure 9 shown.

Embodiment 3

[0081] A two-dimensional HfS prepared by chemical vapor deposition device 2 The method, described chemical vapor deposition device is identical with embodiment 1, and the difference of described method and embodiment 1 is:

[0082] The sources in step (2) are sulfur and hafnium chloride, and the heating and volatilization temperatures are 130° C. and 170° C. respectively. The hafnium chloride is placed upstream of the gas flow, and the sulfur is placed downstream of the zirconium chloride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com