A kind of method that utilizes organic macromolecule material as catalyst to prepare ito nanowire

A technology of organic macromolecules and nanowires, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, it can solve the problems of poor morphology control quality, harsh control process, and high catalyst cost, and achieve good results. Light transmission performance, good performance stability, and the effect of reducing experimental costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

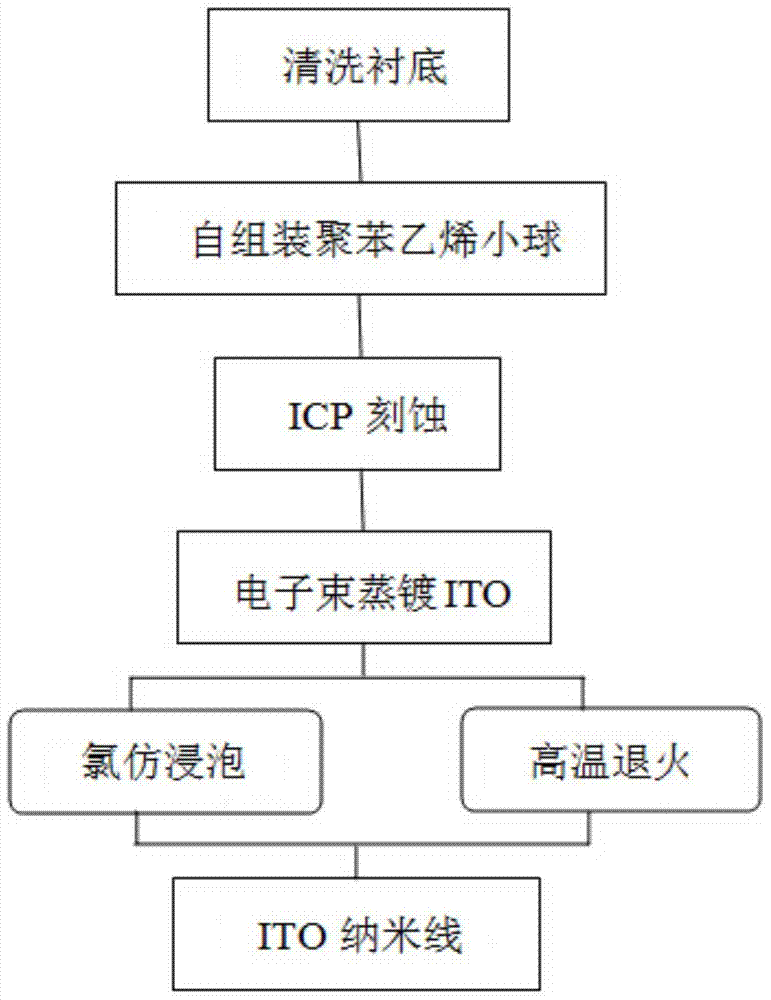

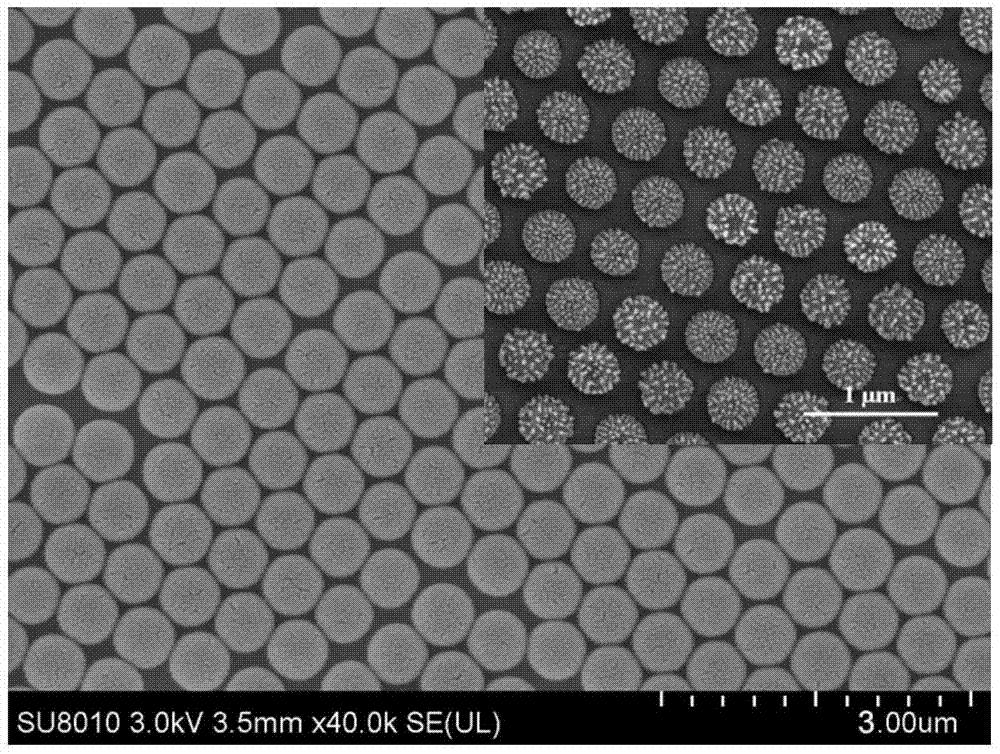

[0036] see figure 1 Shown, a kind of method utilizing organic macromolecular material of the present invention to prepare ITO nanowire by catalysis comprises the following steps: a GaN epitaxial wafer with a diameter of 2 inches is put into acetone and ethanol (99.7%) solvent respectively and ultrasonically cleaned at room temperature 10 minutes, then rinsed with deionized water and blown dry with nitrogen. A single-layer polystyrene pellet with a diameter of 500 nm was self-assembled and deposited on a cleaned GaN epitaxial wafer. The deposition area covered the entire substrate. The surface of the sample was observed with a field emission scanning electron microscope (SEM), and the following results were obtained: figure 2 The results shown. Carry out ICP etching with oxygen afterwards 200 seconds, carry out SEM observation again, obtain as follows figure 2 In the results shown in the middle inset, it can be seen that the surface of the polystyrene spheres is modified an...

Embodiment 2

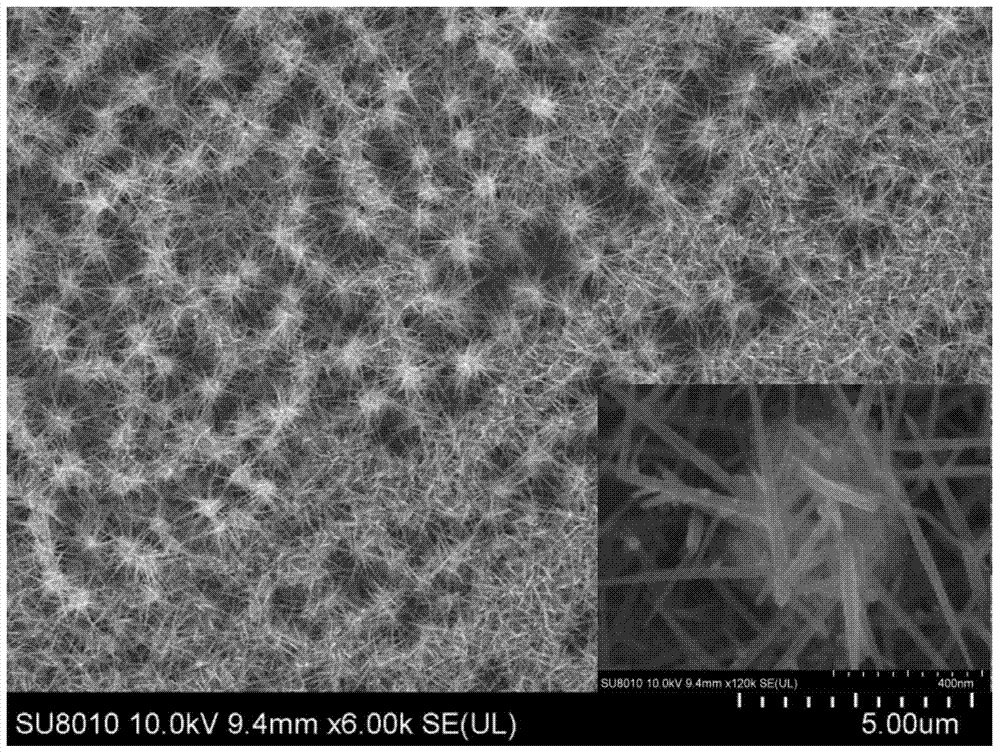

[0040]Complete the ITO evaporation of the GaN epitaxial wafer according to the steps in the implementation case 1, and then put it into the annealing furnace (rapid alloy furnace, model: RTP-3, heating rate 100°C / s, cooling rate 80°C / s) for annealing The temperature is 600°C, the flow rate of nitrogen gas is adjusted to 25ml / min, and annealing is carried out for 10 minutes. After cooling, the substrate is taken out and observed by a field emission scanning electron microscope. The following can be obtained: Figure 5 The results shown. It can be seen that the morphology of ITO nanowires remains the same after high-temperature annealing, and has good electrical conductivity and light transmission properties.

Embodiment 3

[0042] see figure 1 Shown, a kind of method utilizing organic macromolecular material of the present invention to prepare ITO nanowire by catalysis comprises the following steps: a GaN epitaxial wafer with a diameter of 2 inches is put into acetone and ethanol (99.7%) solvent respectively and ultrasonically cleaned at room temperature 10 minutes, then rinsed with deionized water and blown dry with nitrogen. A single-layer polystyrene sphere with a diameter of 500 nm is self-assembled and deposited on a cleaned GaN epitaxial wafer, and the deposition area covers the entire substrate. Afterwards, ICP etching was performed with oxygen for 200 seconds to modify the surface of the polystyrene beads, and to increase the distance between the beads.

[0043] Put the GaN epitaxial wafer with polystyrene balls attached on the sample holder of the electron beam evaporation equipment, and the side with polystyrene balls is facing the ITO target. After loading the ITO target (In:Sn=90:10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com