Rapid light curing DLP 3D printing device

A printing equipment, light curing technology, applied in metal processing equipment, 3D object support structure, additive manufacturing, etc., can solve the problems of not being able to buy transparent ion exchange membranes, and oxygen ion exchange membranes are expensive, to avoid deformation, reduce Input costs, the effect of reducing input and use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

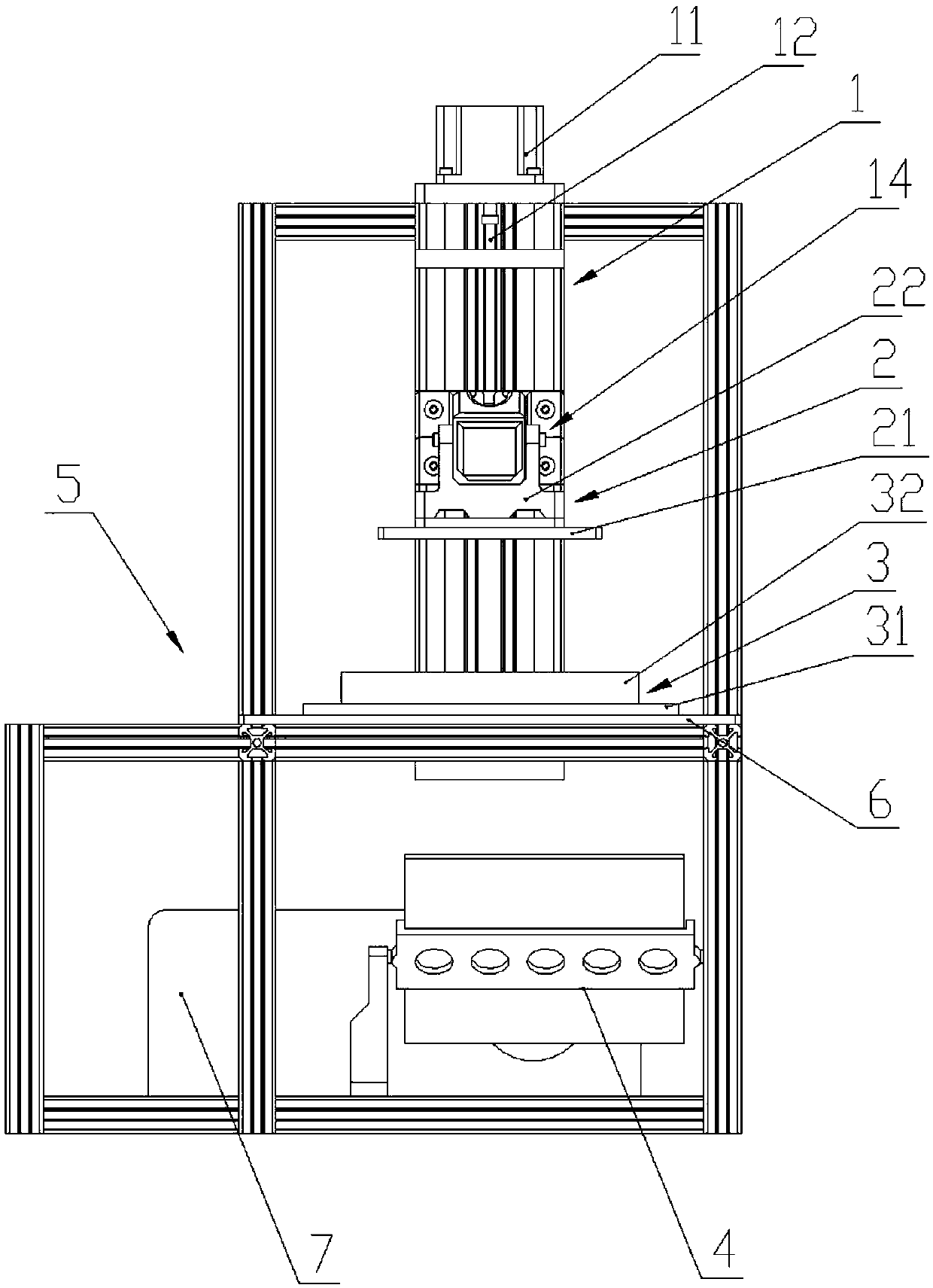

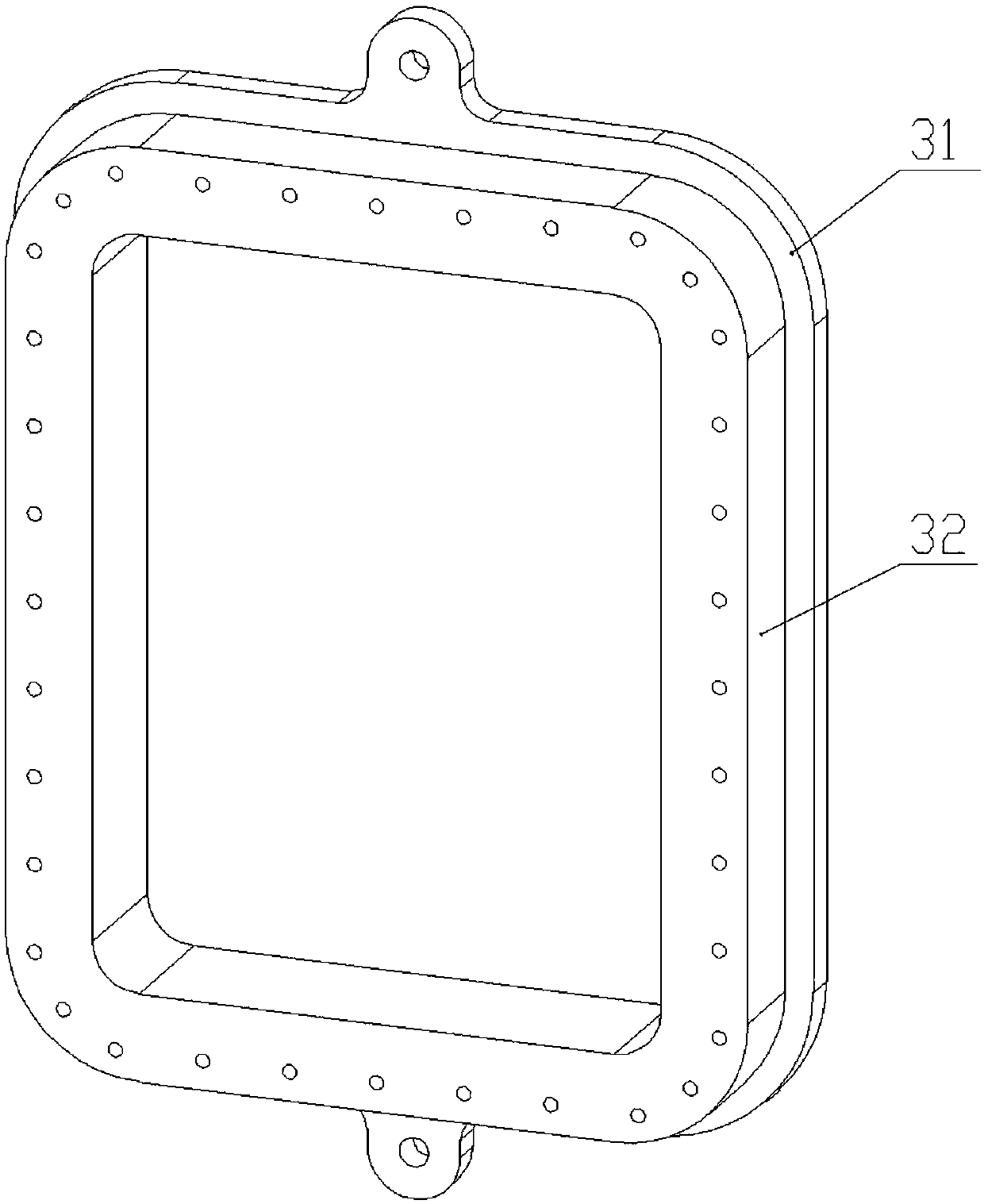

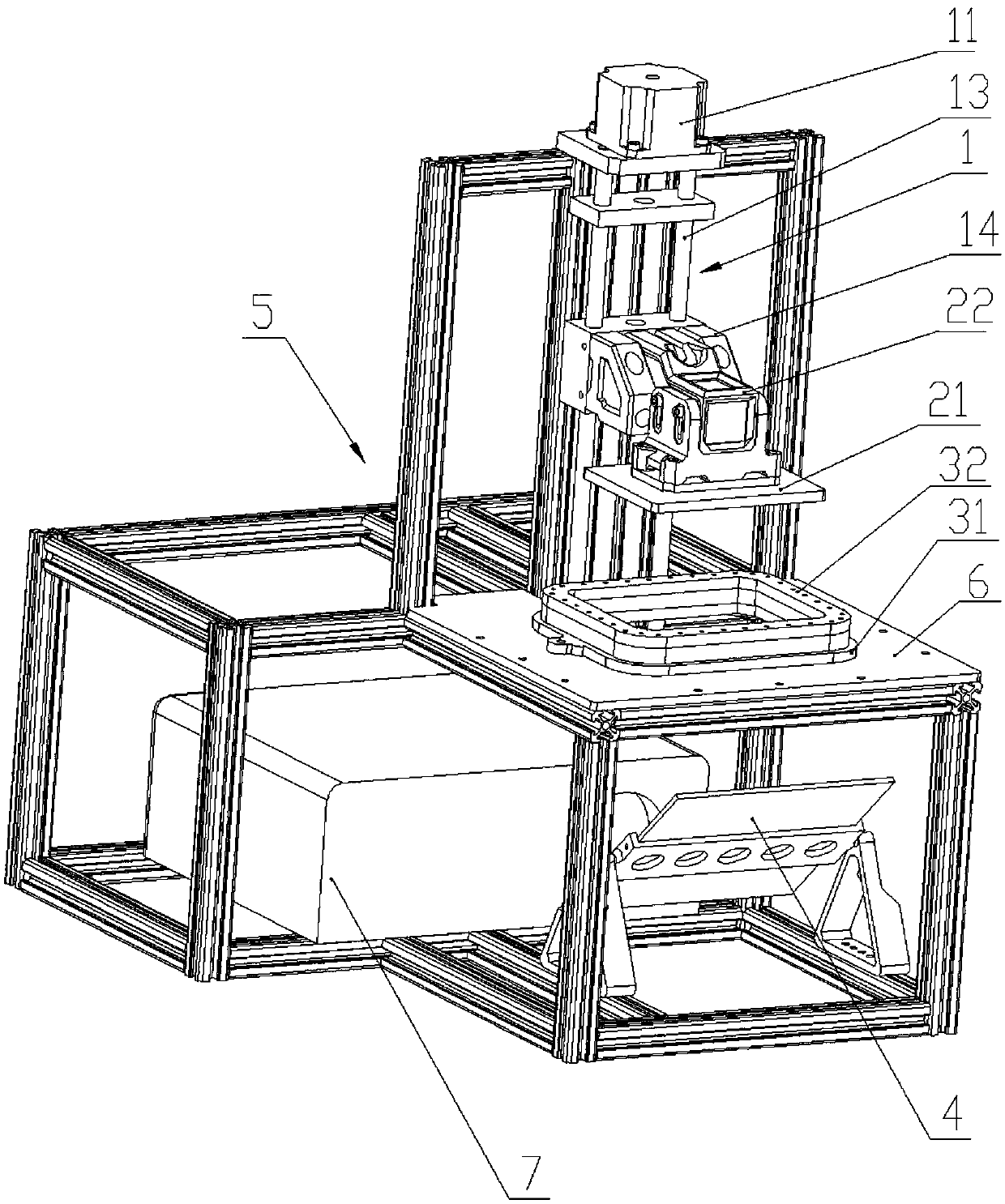

[0030] to combine figure 1 and image 3 It can be seen that the fast photocuring DLP 3D printing device disclosed in this embodiment includes a Z-axis motion module 1, a motion forming platform 2, a resin tank 3, a reflector 4, a frame 5, a resin tank support plate 6, and a light source 7.

[0031] The frame 5 of this embodiment is a frame-type structure assembled from European standard 2020 aluminum profiles. The European standard 2020 aluminum profiles have good straightness, which can ensure that the frame has good flatness, thereby ensuring that the Z-axis motion module The vertical flatness of the resin tank and the horizontal flatness of the resin tank ultimately ensure the quality of the printed body.

[0032] In addition, the 2020-rate profile has its own longitudinal groove, which facilitates the quick installation and fixing of the mirror and resin tank support plate on the frame.

[0033] The light source 7 and the reflective mirror 4 are all installed on the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com