Reflective Articles Comprising A Micro-Cellular Structure And Having Improved Reflectivity

A technology of reflectivity and pore structure, which can be applied to home appliances, other home appliances, applications, etc., and can solve the problem that purple pump LEDs do not show optical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

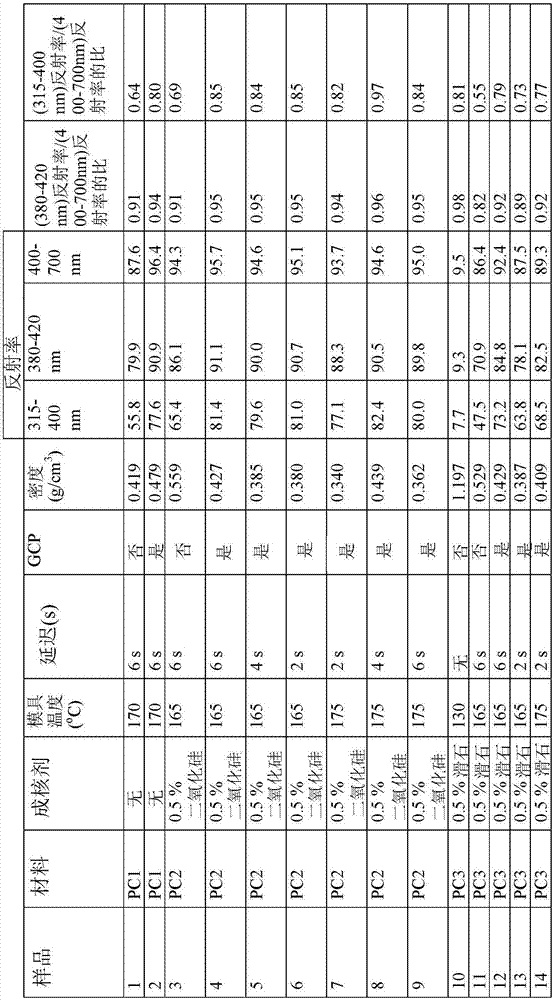

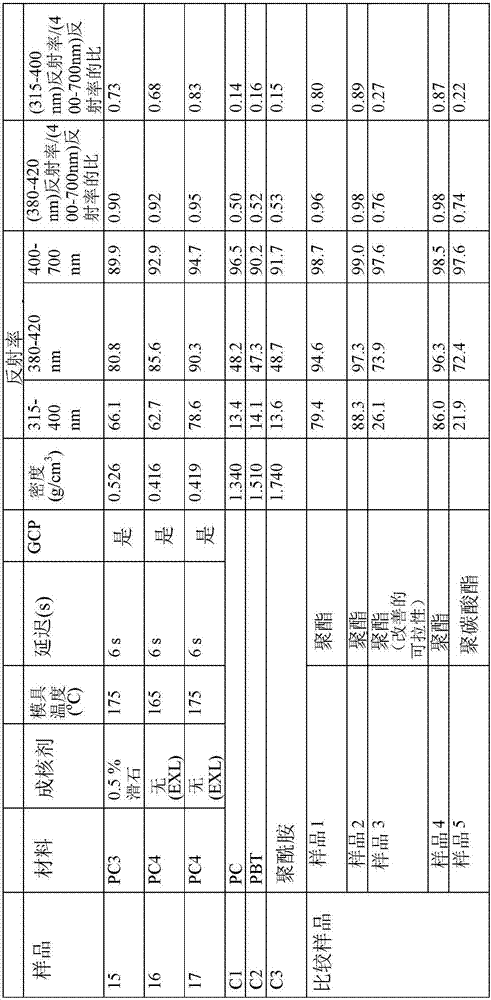

[0090] As explained herein, the foam cell structure exhibits improved reflectivity at specific wavelengths such as the 315-420 nm range; the reflectance in the 380-420 nm range is of particular interest. Without being bound by any particular theory, generally the smaller the pore size, the higher the reflectivity.

[0091] Exemplary foam / microcellular structures can be obtained by forming cells equipped with pore forming technology (e.g. MuCell TM Technology) and injection molding machine with heating and cooling capabilities to obtain PC by injection molding. For the examples given herein, nitrogen was used as the "bubbling" gas, although other gases are known to those skilled in the art.

[0092] For these exemplary materials, the MuCell unit injected nitrogen gas under high pressure (350 bar) into molten polycarbonate (PC) (with a weight average molecular weight of about 70 kilodaltons, based on polystyrene), which was injected into the heated mold. Gas backpressure can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com