Process for producing roll of microporous plastic film

A technology of microporous plastics and manufacturing methods, which is applied in thin material processing, winding strips, electrolytic capacitors, etc., can solve the problems of wrinkles and breakage, difficult handling, etc., and achieve the effect of high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

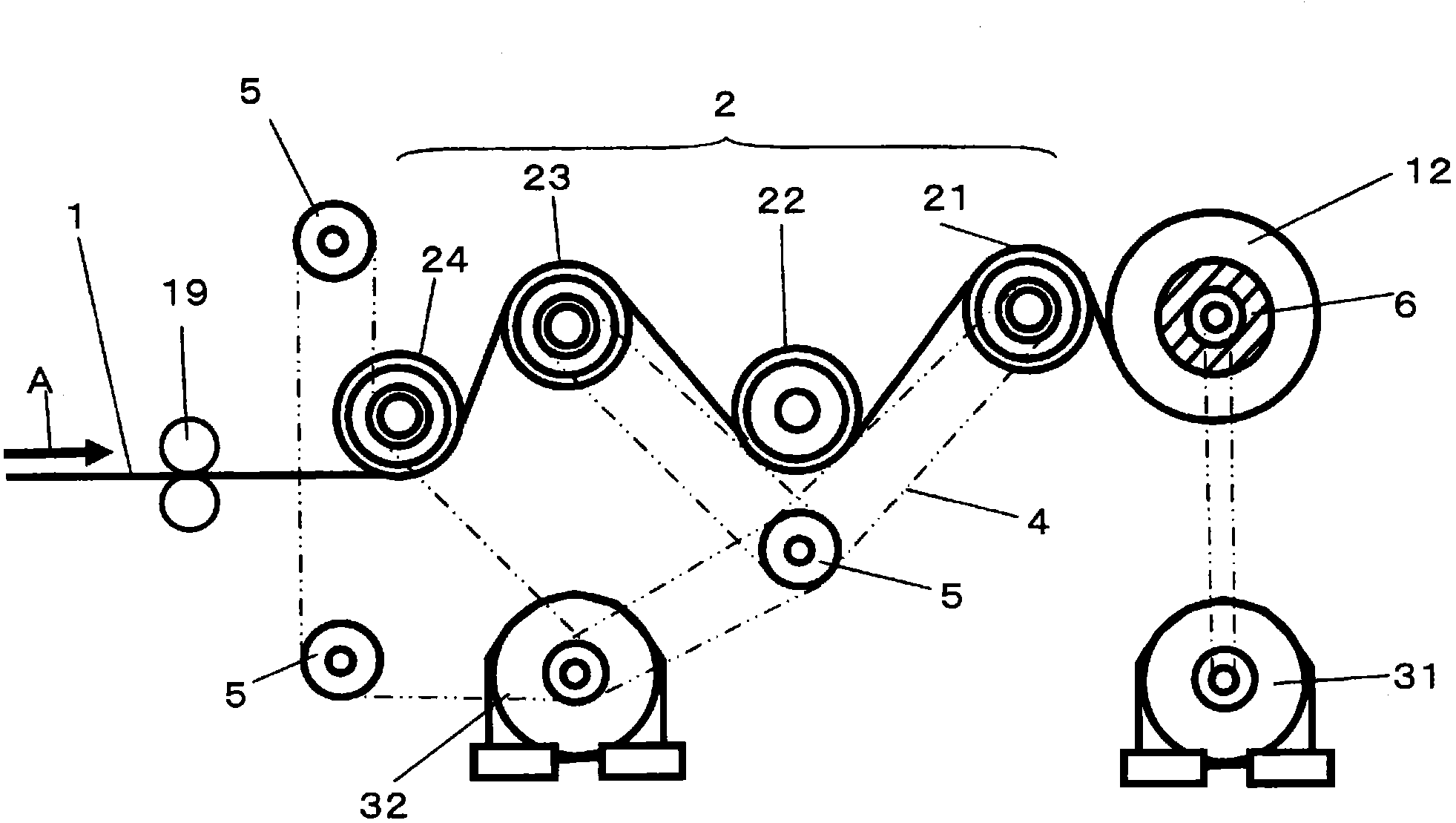

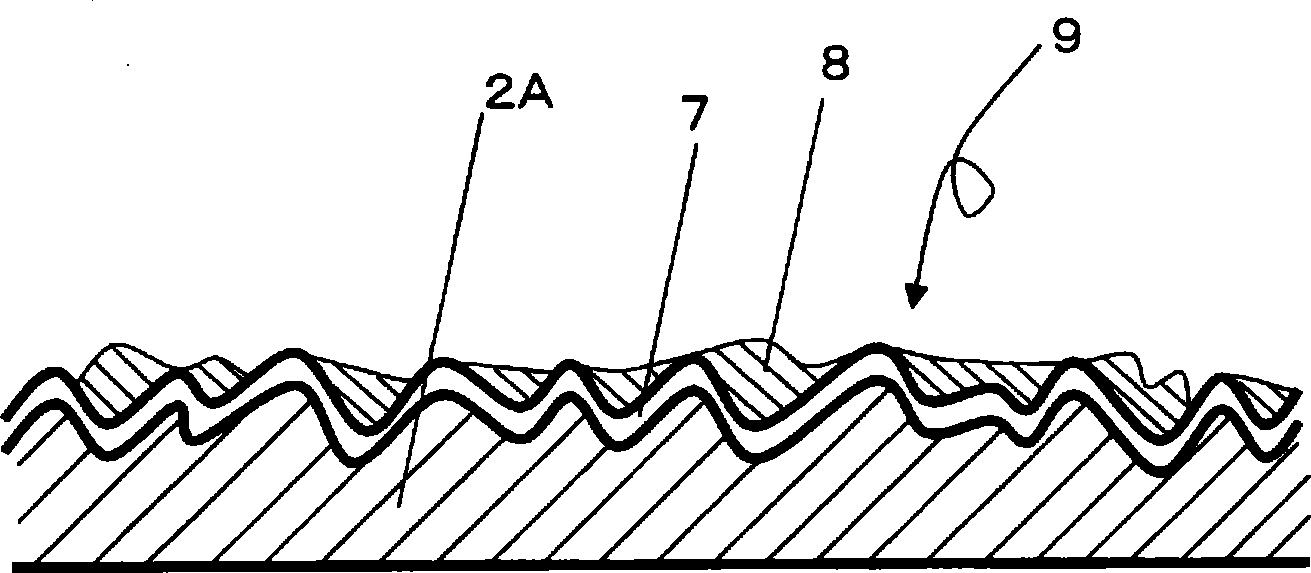

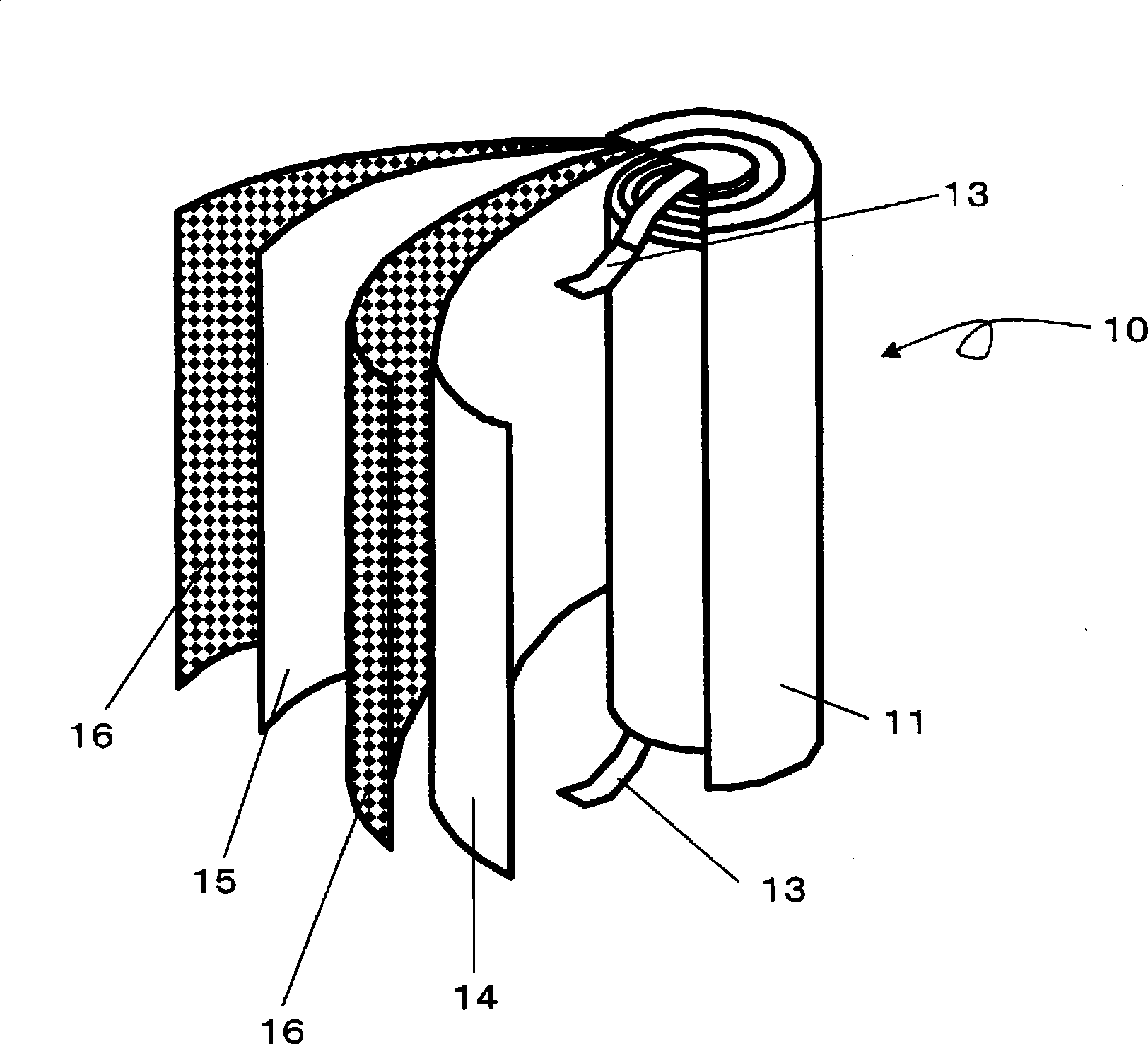

[0104] Controlling the crystalline structure of polypropylene, utilizing figure 1Such conveying rollers 2 are formed by a biaxial stretching process. Figure 4 The polypropylene microporous plastic film 1 with such a through-hole was conveyed and wound up continuously on the core 6 to manufacture the microporous plastic film roll 12 . The Gurley air resistance value of the polypropylene microporous membrane is 500 seconds / 100ml, the porosity is 70%, the average pore diameter is 100nm, and the buffer rate is 17%. The film 1 has a width of 600 mm and a thickness of 60 μm. The thickness was measured by a light emitting and receiving type laser sensor, and the porosity was obtained by Equation 6 based on the measured thickness.

[0105] Here, air permeability is based on JISP8117 (2001), and can be represented by the Gurley air resistance value (second / 100ml). The Gurley air resistance value is the passage time of the microporous membrane under the condition of pressing 100ml o...

Embodiment 2

[0122] A film 1 having a thickness of 20 μm was wound up under the same conditions as in Example 1 to manufacture a microporous plastic film roll 12 . The porosity of this film was the same as that of Example 1, and the Gurley air permeability resistance value was 100 seconds / 100 ml due to the thinner thickness.

Embodiment 3

[0124] With respect to Example 2, in order to make the friction coefficients of the four parts of the conveying rollers 21 to 24 in contact with the film 1 be 0.5 or less, on the surfaces of these rollers, figure 2 In that form, a composite film of polytetrafluoroethylene (PTFE) and metal is formed. Regarding the surface roughness of the roll surface, ten-point average roughness was measured under the same conditions as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com