Experimental facility for dissolving supercritical CO2 in polymer melt under condition of interface updating

A technology for updating conditions and experimental devices, used in measuring devices, instruments, scientific instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

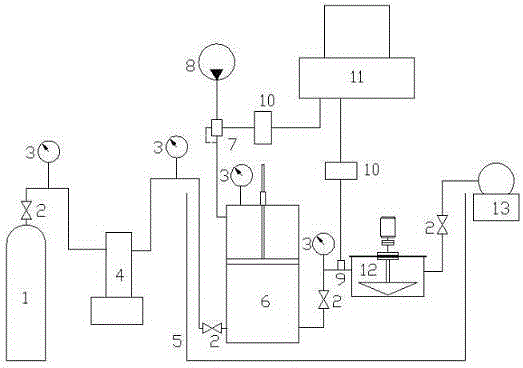

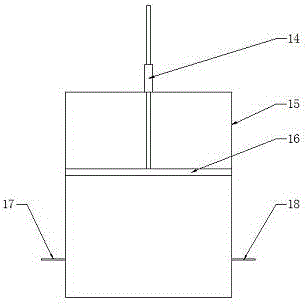

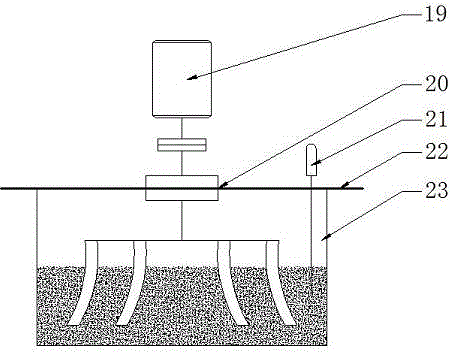

[0024] Supercritical CO under the interface renewal condition of the present invention 2 The schematic diagram of the overall structure of the dissolution experimental device in the polymer melt is shown in figure 1 As shown, its structure includes gas cylinder (1), pressure reducing valve (2), pressure digital display gauge (3), booster pump (4), oil bath heating container (5), pressure chamber 1 (6), overflow Flow valve (7), oil pump (8), pressure sensor (9), A / D converter (10), control system (11), pressure chamber 2 (12), magnetic stirring device (19), vacuum pump (13) , the upper part of the pressure chamber 1 (6) is connected with the gas cylinder (1) and the booster pump (4), and there is a pressure reducing valve (2) and a pressure digital display meter (3) between the gas cylinder and the booster pump, CO 2 The gas cylinder (1) is connected to the pressure chamber 1 (6), and the upper end of the pressure chamber 1 (6) is connected with a constant oil pressure to cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com