Frost crack resisting drainage pipeline and manufacturing method thereof

A drainage pipe and anti-freeze cracking technology, which is applied in the direction of general water supply saving, pipes, rigid pipes, etc., can solve the problems of drainage pipes being easily cracked by freezing, and achieve the effects of simple assembly and manufacturing operations, reduced maintenance, and improved product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

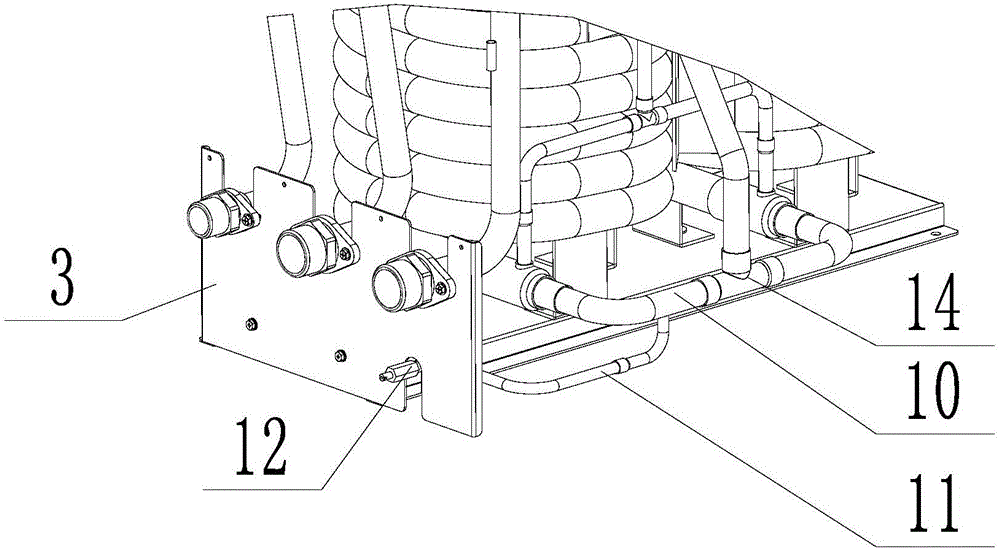

[0025] Such as figure 1 As shown, the drain pipe 1 of the water heater is installed on the water pipe bracket 3 of the water heater 2 . In the figure, a flow divider 14, a water inlet pipe 10, a drain pipe 11, a drain valve 12, and a water pipe bracket 3 are included.

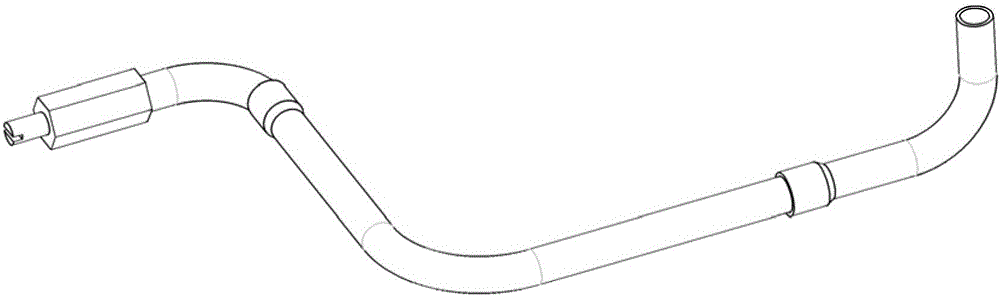

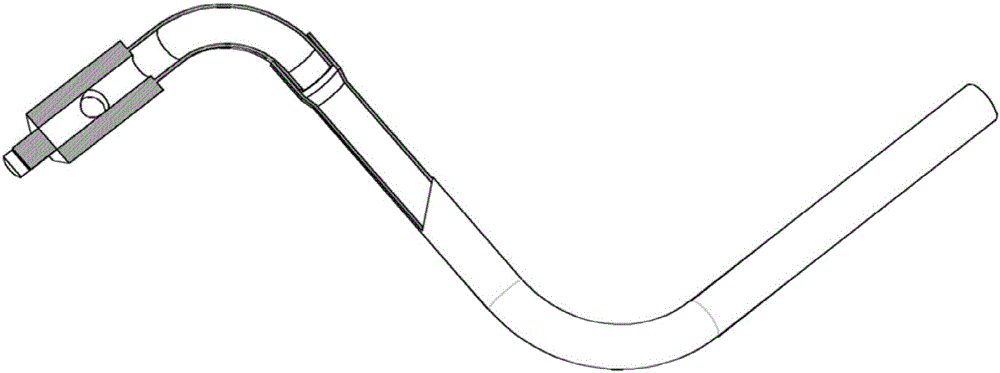

[0026] The appearance and cross-sectional diagram of the existing drainage pipe are as follows: figure 2 with image 3 shown in .

[0027] Figure 4 A schematic cross-sectional view of the antifreeze crack drainage pipe provided by the embodiment of the present invention is shown. Wherein, the antifreeze crack drainage pipeline 1 includes a drainage pipe 11 and a drainage valve 12 . combine figure 1 As shown, it can be seen that the entire d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com