Novel single-row tube bank for cooling air

A new type of air cooling technology, applied in tubular components, lighting and heating equipment, heat exchange equipment, etc., can solve the problems of increased system cleaning times, high raw material cost, large base pipe cross-section, etc., to ensure thermal conductivity, reduce Enhanced heat exchange efficiency and antifreeze capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

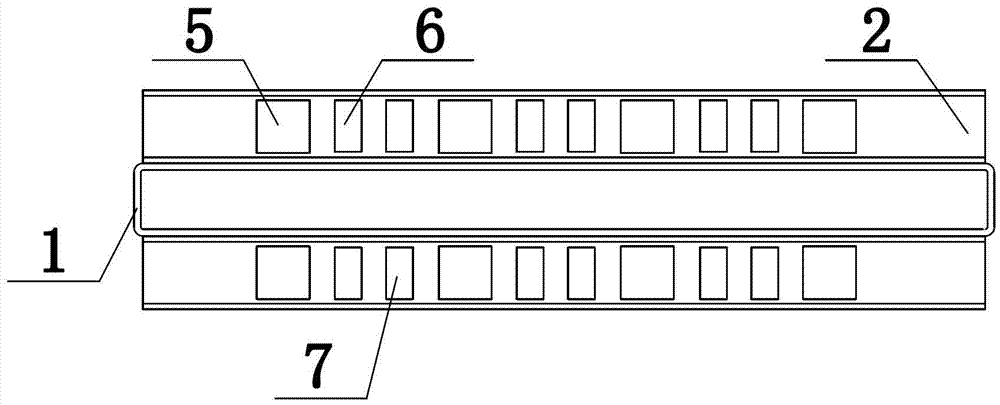

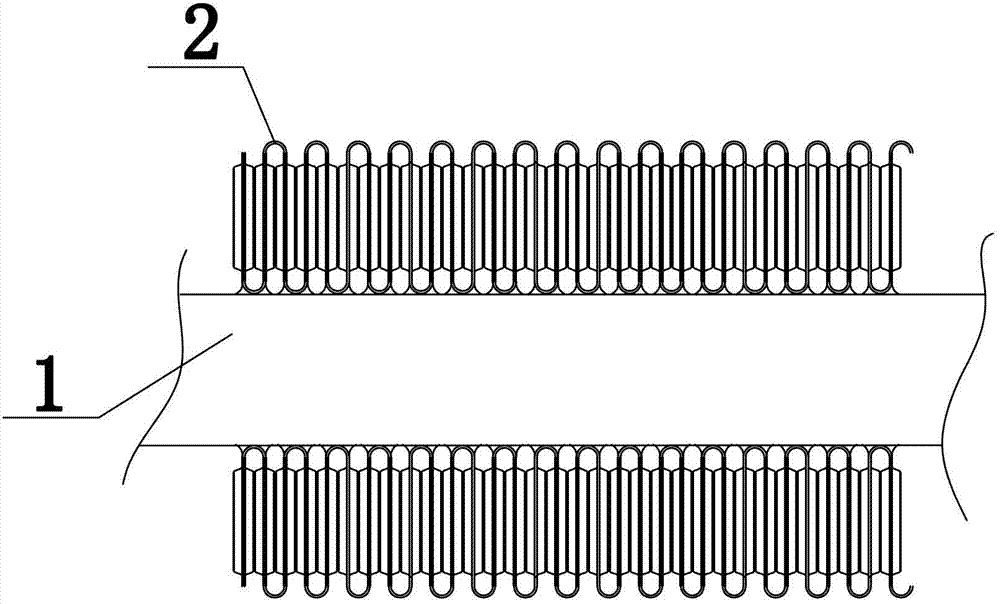

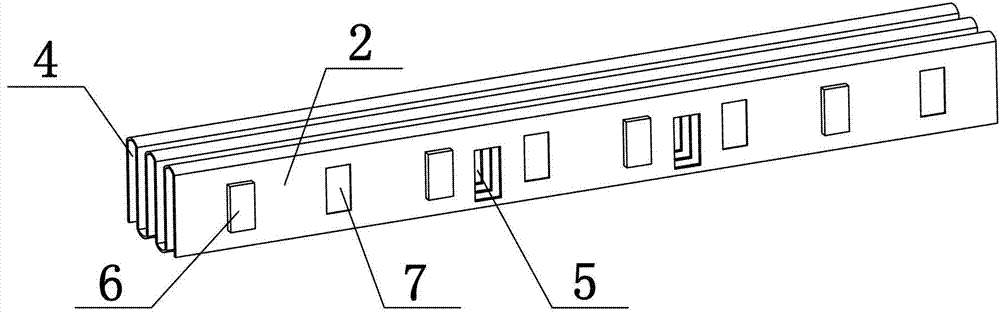

[0029] Embodiment 1 of the present invention: as figure 1 , figure 2 As shown, a new type of single-row tube bundle for air cooling, including a base tube 1 and fins 2, the base tube 1 is a rectangular flat tube with chamfers, the fins 2 are arranged on the upper and lower surfaces of the base tube 1, the base tube 1 The fins 2 are welded together by integral brazing, the fins 2 are serpentine, and the fins 2 are provided with spoiler holes 5 .

[0030] The number of spoiler holes 5 on the fin 2 is an even number, and the spoiler holes 5 are evenly distributed on the fin 2 .

[0031] The shape of the spoiler hole 5 is rectangular.

[0032] The fins 2 are also provided with protrusions 6 and grooves 7 , and the protrusions 6 and grooves 7 are alternately distributed on the fins 2 .

[0033] Such as Figure 5 As shown, the spoiler hole 5 is provided with a spoiler 3 having the same shape as the spoiler hole.

[0034] Such as Figure 7 As shown, the angle α between the spo...

Embodiment 2

[0040] Embodiment 2 of the present invention: as figure 1 , figure 2 As shown, a new type of single-row tube bundle for air cooling, including a base tube 1 and fins 2, the base tube 1 is a rectangular flat tube with chamfers, the fins 2 are arranged on the upper and lower surfaces of the base tube 1, the base tube 1 The fins 2 are welded together by integral brazing, the fins 2 are serpentine, and the fins 2 are provided with spoiler holes 5 .

[0041] The number of spoiler holes 5 on the fin 2 is an even number, and the spoiler holes 5 are evenly distributed on the fin 2 .

[0042] Such as Figure 6 As shown, the shape of the spoiler hole 5 is a triangle.

[0043] The fins 2 are also provided with protrusions 6 and grooves 7 , and the protrusions 6 and grooves 7 are alternately distributed on the fins 2 .

[0044] A spoiler 3 having the same shape as the spoiler hole is provided on the spoiler hole 5 .

[0045] Such as Figure 7 As shown, the angle α between the spoil...

Embodiment 3

[0051] Embodiment 3 of the present invention: as figure 1 , figure 2 As shown, a new type of single-row tube bundle for air cooling, including a base tube 1 and fins 2, the base tube 1 is a rectangular flat tube with chamfers, the fins 2 are arranged on the upper and lower surfaces of the base tube 1, the base tube 1 The fins 2 are welded together by integral brazing, the fins 2 are serpentine, and the fins 2 are provided with spoiler holes 5 .

[0052] The number of spoiler holes 5 on the fins 2 is an even number.

[0053] The shape of the spoiler hole 5 is rectangular.

[0054] The fins 2 are also provided with protrusions 6 and grooves 7 , and the protrusions 6 and grooves 7 are alternately distributed on the fins 2 .

[0055] Such as Figure 5 As shown, the spoiler hole 5 is provided with a spoiler 3 having the same shape as the spoiler hole.

[0056] Such as Figure 7 As shown, the angle α between the spoiler 3 and the fin 2 is 30°.

[0057] The material of the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com