Apparatus and method for extrusion moulding of supercutical-fluid micropore plastic

A technology of supercritical fluid and extrusion molding, which is applied in the field of continuous extrusion molding of microporous plastics. It can solve problems such as large pressure fluctuations, easy material accumulation, and small screw length and diameter, so as to improve gas utilization and conveying efficiency. , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

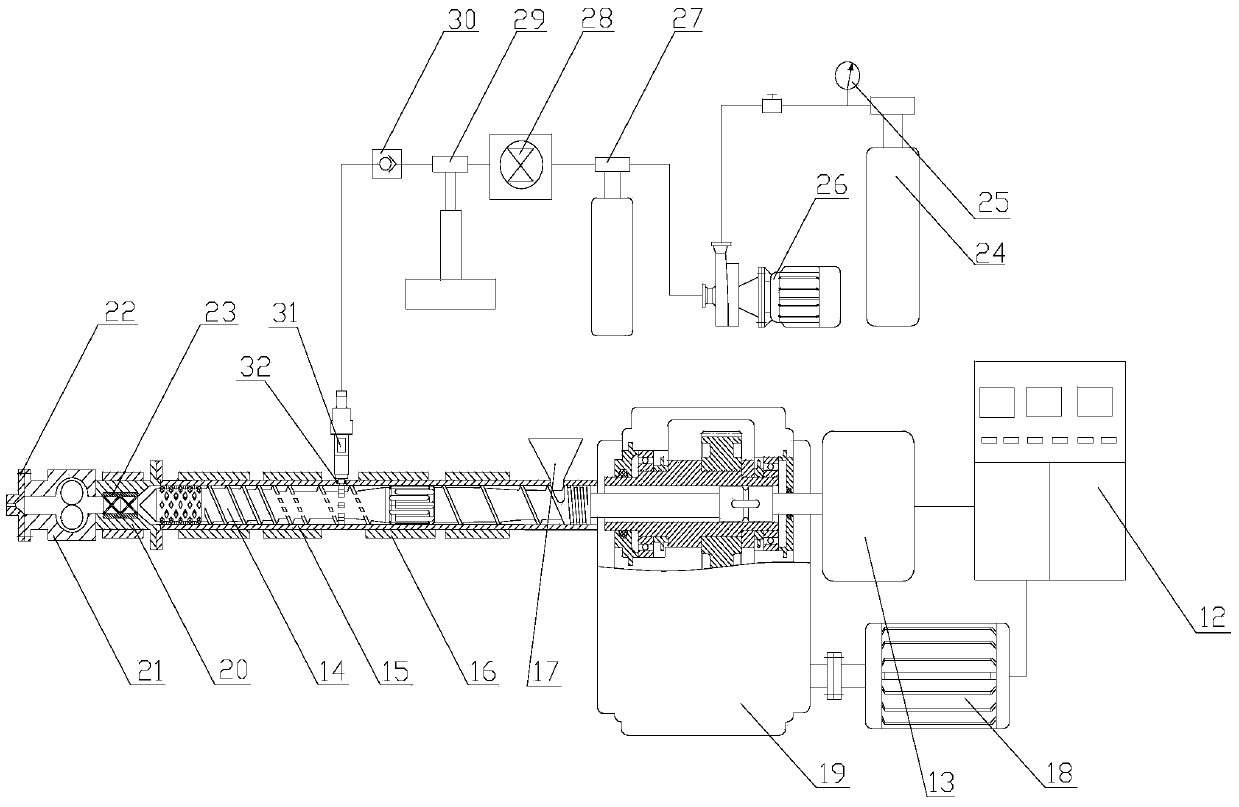

[0035] In this embodiment, a supercritical fluid microporous plastic extrusion molding device, such as figure 1 As shown, it includes an electric control box 12, a vibrator 13, a power unit, a plasticizing mixing unit, a supercritical fluid delivery unit and a molding unit, and the vibrator, the power unit, the plasticizing mixing unit and the molding unit are connected in sequence, and the plasticizing The mixing unit is provided with a supercritical fluid delivery unit, and the exciter, the power unit and the plasticizing mixing unit are respectively electrically connected to the control box.

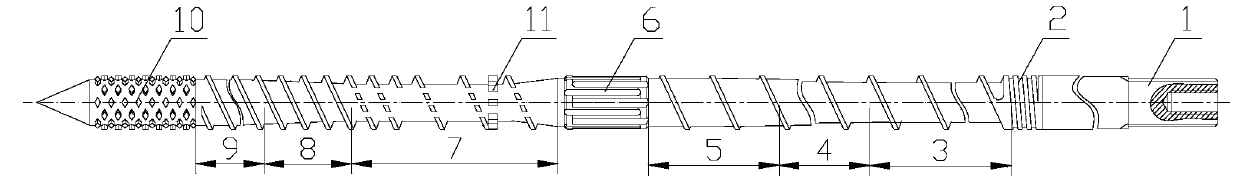

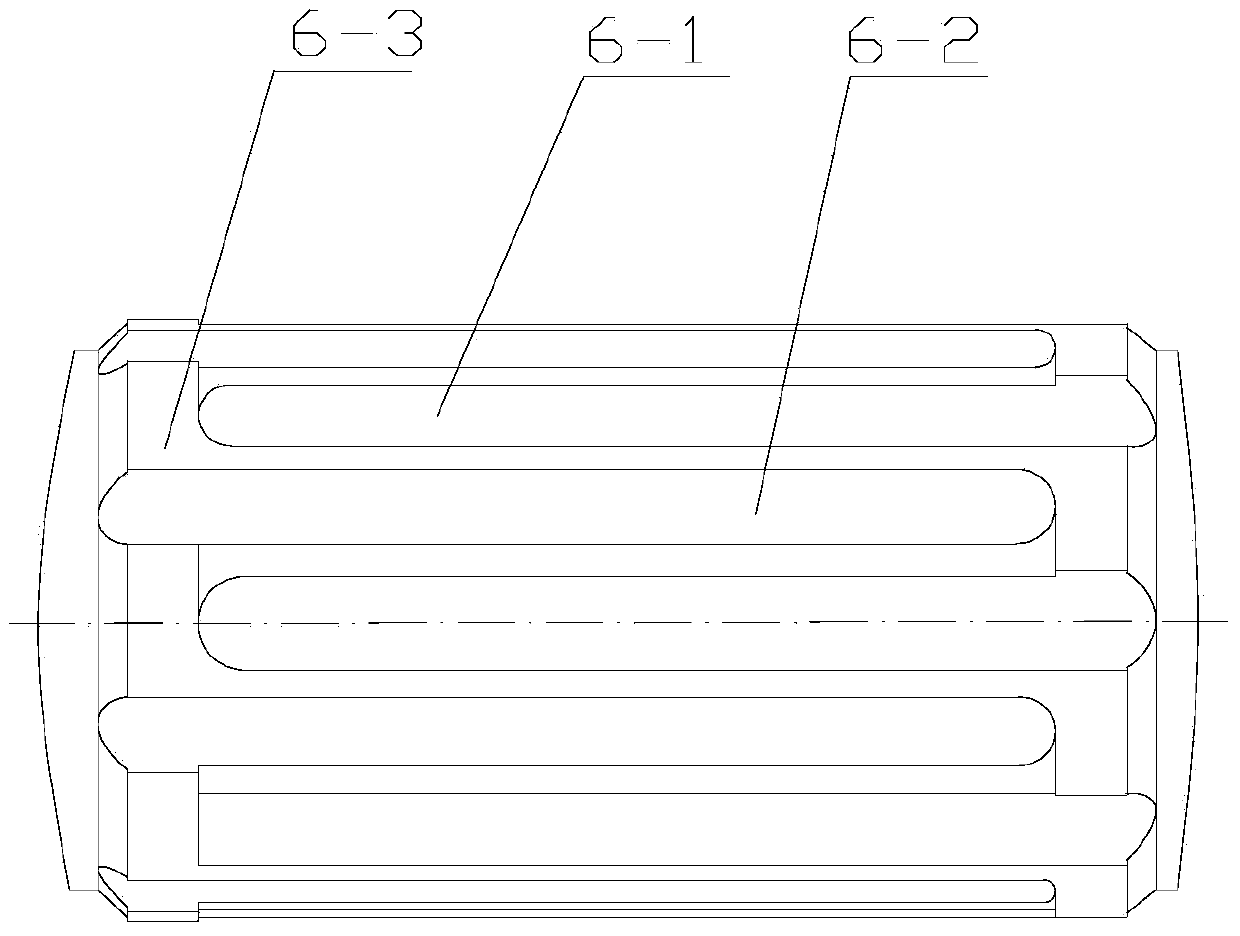

[0036] The plasticizing mixing unit includes a screw 14, a barrel 15, a heater 16 and a hopper 17. The screw is placed in the barrel, and the outer periphery of the barrel is equipped with a heater. The barrel at the feeding end of the screw is provided with a hopper. A supercritical fluid gas injection hole is provided, and the supercritical fluid gas injection hole is connected with...

Embodiment 2

[0050] This embodiment is a supercritical fluid microporous plastic extrusion molding device. Compared with Embodiment 1, the difference is that the molding unit is an extruder head, and the extruder head is fixedly connected with the barrel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com