Preparing method for ablation-resistant high-ortho phenolic fibers

A high-ortho-position, boron-phenolic technology, which is applied in the fields of fiber chemical characteristics, melt spinning, chemical post-treatment of synthetic polymer artificial filaments, etc., can solve the problems of long-term application in special fields, lack of ablation resistance, and fiber mechanical properties Poor problems, achieve high O/P) value, fast curing rate, improved mechanical properties and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Mix phenol (100g) and formaldehyde (68.9g) according to the molar ratio of 1:0.8, then add 1g of titanium citrate catalyst, boil for 2.9h; add diluted concentrated sulfuric acid (concentrated sulfuric acid is 0.1ml), continue the reaction for 50min; reduce pressure Dehydration for 0.5h, the temperature of the resin reaches 90°C; add 1g of boric acid for modification reaction, and boil at constant temperature for 2 hours; dehydration under reduced pressure, when the resin temperature rises to 100°C, the material is discharged to obtain a molecular weight of 26000Da, O / P (o High ortho boric acid phenolic resin with a para-position ratio) value of 4.5 and a viscosity of 24.5cP at 140°C;

[0027] The resin was melt-spun at 120°C, and the nascent fibers were put into the prepared solidification solution (aqueous solution with a mass fraction of formaldehyde of 8% and a mass fraction of hydrochloric acid of 12%), and the temperature was gradually raised from room temperature (...

Embodiment 2

[0031] Mix phenol (100g) and formaldehyde (73.3g) according to the molar ratio of 1:0.85, then add 2g of titanium citrate catalyst, boil for 2h; add dilute concentrated sulfuric acid (concentrated sulfuric acid is 0.3ml), continue the reaction for 30min; dehydration under reduced pressure 3h, the temperature of the resin reaches 97°C; add 10g of boric acid for modification reaction, boil at constant temperature for 2 hours; dehydrate under reduced pressure, when the resin temperature rises to 130°C, the material is discharged to obtain a molecular weight of 5000Da, O / P (ortho-para High ortho boric acid phenolic resin with a ratio of 7.8 and a viscosity of 9.5cP at 140°C;

[0032] The resin was melt-spun at 160°C, and the nascent fiber was put into the prepared solidification solution (formaldehyde mass fraction 6%, hydrochloric acid mass fraction 12% aqueous solution), and the temperature was gradually raised from room temperature (6°C every 2 minutes) to 95°C, constant temper...

Embodiment 3

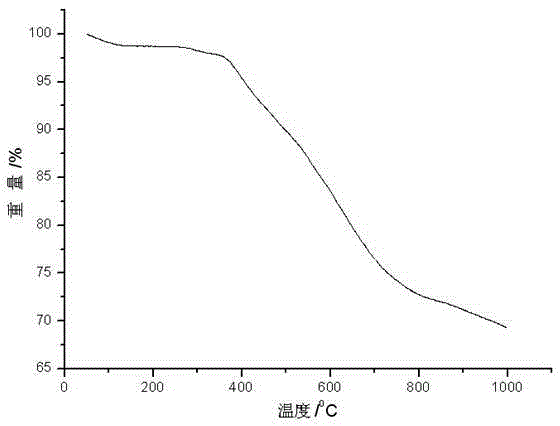

[0036] The high-ortho-boron phenolic fiber and phenolic resin obtained in embodiment 2 are compounded according to a mass ratio of 4:6 to obtain a high-ortho-boron phenolic fiber / phenolic resin composite material, and the thermal conductivity of the composite material is 0.39W / m*K, The linear ablation rate is -0.010mm / s, the mass ablation rate of oxyacetylene flame is 0.0213g / s, and the density is 1.31g / cm 3 , 1000 ℃ under nitrogen atmosphere, the carbon residue is 75%, and the limiting oxygen index is 40. The results show that the composite material has good interfacial bonding, excellent ablation resistance, better heat insulation, heat resistance and flame retardancy than phenolic resin, and the synergistic effect is obvious.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com