Tungsten mesh toughened hafnium carbonitride-based metal ceramic and preparation method thereof

A hafnium carbonitride matrix, carbonitriding technology, applied in the field of tungsten mesh toughened hafnium carbonitride-based cermets and its preparation, can solve the problem of low fracture toughness, achieve short preparation cycle and easy preparation process , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

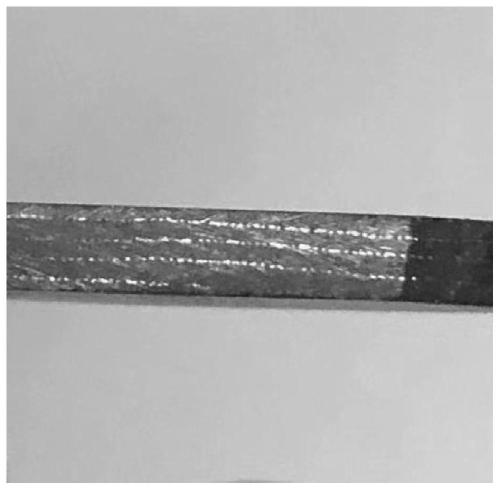

[0042]Mix HfC powder, HfN powder, carbon powder, and carbon nitride powder, and then ball mill it on a planetary ball mill for 10 hours. ℃ in a drying oven for 8 hours, and the mixed powder was obtained after sieving. The purity of each raw material powder is greater than 99.9%, and the average particle size of the powder is 1um. In the mixed powder, the mass ratio of HfC powder to HfN powder is 3:2; and the mass fraction of carbon powder in the mixed powder is 5%. The mass fraction of carbon nitride in the mixed powder is 5%.

[0043] Select a 100-mesh tungsten mesh with a purity greater than 99.9%. After 30 minutes of ultrasonic cleaning with ethanol, it is dried and taken out, and cut into the diameter of the abrasive tool. Then the mixed powder and tungsten mesh are evenly and alternately placed in the graphite mold, arranged in 5 layers, the thickness of the sintered body is 10mm, and the discharge plasma sintering is carried out. The vacuum degree in the furnace is less...

Embodiment 2

[0045] Mix HfC powder, HfN powder, carbon powder, and carbon nitride powder, and then ball mill it on a planetary ball mill for 12 hours. Dry in a drying oven at ℃ for 10 hours, and obtain mixed powder after sieving, wherein the purity of each raw material powder is greater than 99.9%, and the average particle size of the powder is 1um. In the mixed powder, the mass ratio of HfC powder to HfN powder is 2:1; while the mass fraction of carbon powder in the mixed powder is 4%, and the mass fraction of carbon nitride in the mixed powder is 4%.

[0046] Select 80-mesh tungsten mesh with a purity greater than 99.9%. After 20 minutes of ultrasonic cleaning with ethanol, it is dried and taken out, and cut into the diameter of the abrasive tool. Then place the mixed powder and tungsten mesh evenly and alternately in the graphite mold, a total of four layers of tungsten mesh, the thickness of the sintered body is 8mm, and conduct spark plasma sintering. To 2100°C, keep warm for 15 minu...

Embodiment 3

[0048] Mix HfC powder, HfN powder, carbon powder, and carbon nitride powder, and then ball mill it on a planetary ball mill for 12 hours. The ball milling medium is ethanol solution, the speed is 200r / min, the ratio of ball to material is 9:1, and then placed at 70°C Dry it in a drying oven for 10 hours, and obtain the mixed powder after sieving. The purity of each raw material powder is greater than 99.9%, and the average particle size of the powder is 1um. In the mixed powder, the mass ratio of HfC powder to HfN powder is 3:1; and the mass fraction of carbon powder in the mixed powder is 3%, The mass fraction of carbon nitride in the mixed powder is 4%.

[0049] Select 120-mesh tungsten mesh with a purity greater than 99.9%, and dry it after ultrasonic treatment with ethanol. Cut to the size of the abrasive tool diameter, then place the mixed powder and tungsten mesh evenly and alternately in the graphite mold, a total of six layers of tungsten mesh, the thickness of the si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com