Preparation method of microporous plastic catalytically degrading formaldehyde

A microporous plastic and catalytic degradation technology, applied in the field of formaldehyde purifiers, can solve problems such as affecting the efficiency of formaldehyde catalytic degraders, unable to catalyze degradation of formaldehyde, etc., and achieve the effects of avoiding secondary pollution, high specific surface area, and wide application fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

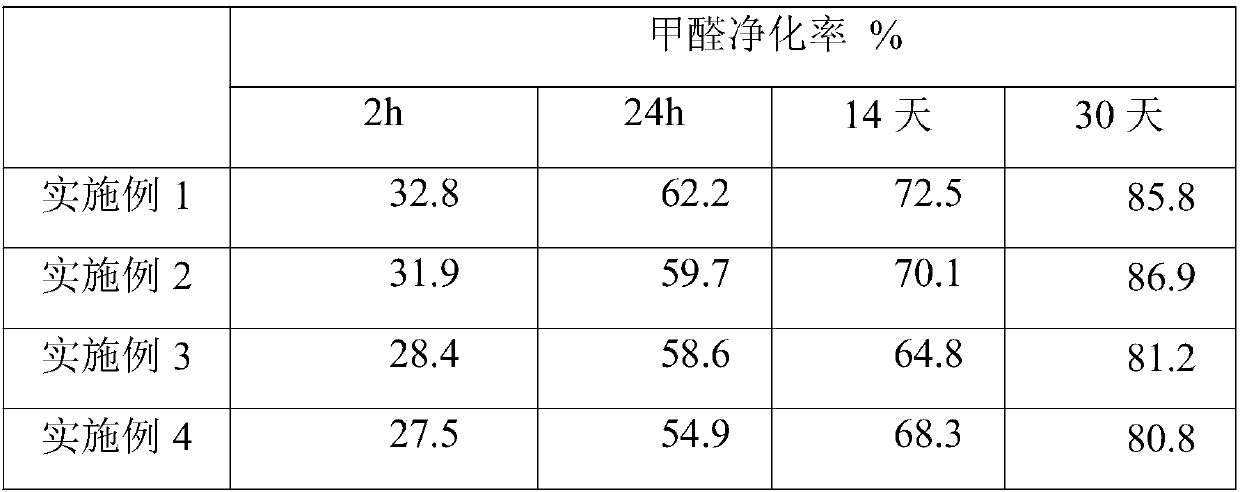

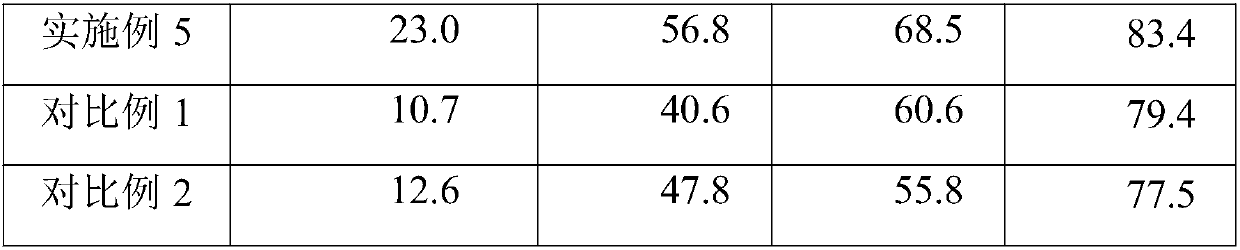

Examples

preparation example Construction

[0013] The present invention also provides a preparation method of the microporous plastic that catalyzes the degradation of formaldehyde, comprising the following steps:

[0014] (1) soaking the plant fibers in an alkaline solution for 5-24 hours to obtain porous plant fibers;

[0015] (2) After uniformly mixing the porous plant fiber, negative ion powder and organic titanate in a solvent, sonicate for 15-30 minutes, and then seal and react at 80-120°C for 3-6 hours to obtain the modified porous plant fiber;

[0016] (3) Add metal powder and modified porous plant fiber to phenolic resin and mix evenly to obtain a composite phenolic resin, then add a curing agent and an acidic solution to the composite phenolic resin, then pour it into a mold, solidify and shape, and obtain catalytic degradation Formaldehyde microporous plastic.

[0017] On the one hand, negative ion powder can release energy and provide energy for catalytic reactions. On the other hand, negative ion powder a...

Embodiment 1

[0025] A microporous plastic that catalyzes the degradation of formaldehyde, made of the following parts by weight: 5 parts by weight of tourmaline powder (with a particle diameter of 200nm), 5 parts by weight of cage core pottery white carbon powder (with a particle diameter of 200nm), ramie fiber 40 parts by weight, 72 parts by weight of sodium hydroxide solution (2M), 6 parts by weight of tetramethyl titanate, 16 parts by weight of phenolic resin, 3 parts by weight of aluminum powder (particle size is 100nm), 5 parts by weight of hydrochloric acid solution (3M) , 3 parts by weight of 1,15-pentadecanediamine, and 50 parts by weight of N,N-dimethylformamide.

[0026] (1) Soak ramie fiber in sodium hydroxide solution (2M) for 12h to obtain porous ramie fiber;

[0027] (2) After mixing porous ramie fiber, tourmaline powder (particle size 200nm), cage core ceramic white carbon powder (particle size 200nm) and tetramethyl titanate in N,N-dimethylformamide , sonicated for 30 minu...

Embodiment 2

[0030] A microporous plastic that catalyzes the degradation of formaldehyde, made of the following parts by weight: 10 parts by weight of tourmaline powder (with a particle size of 500nm), 2 parts by weight of seagull powder (with a particle size of 500nm), 35 parts by weight of cotton fiber, 75 parts by weight of sodium hydroxide solution (2M), 5 parts by weight of tetraisobutyl titanate, 18 parts by weight of phenolic resin, 1 part by weight of magnesium powder (particle size is 200nm), 12 parts by weight of hydrochloric acid solution (3M), 2- 4 parts by weight of methyl-1,5-pentanediamine, and 50 parts by weight of water.

[0031] (1) Soak cotton fiber in sodium hydroxide solution (2M) for 12h to obtain porous cotton fiber;

[0032] (2) After mixing porous cotton fiber, tourmaline powder (particle size 500nm), seagull stone powder (particle size 500nm) and tetraisobutyl titanate in water, ultrasonic for 30min, then sealed and reacted at 100°C for 5h , to obtain modified po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com