Low-density polypropylene foam with heat insulation performance and preparation method and application thereof

A low-density polypropylene and foam technology, applied in the field of low-density polypropylene foam and its preparation, can solve the problems of poor electromagnetic wave absorption capacity, weaken the thermal insulation performance of polypropylene foam products, etc., achieve excellent thermal insulation performance, promote fine The effect of reducing the cell structure and improving the extrusion foaming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

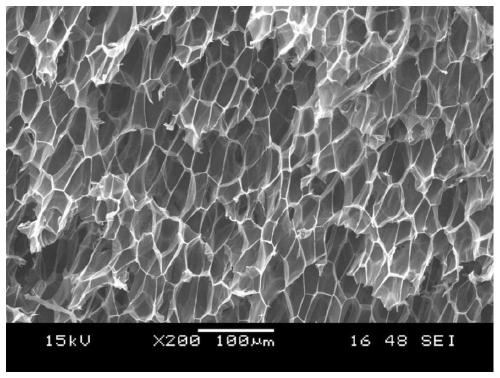

no. 1 example

[0044] Raw materials include: high melt strength PP produced by Borealis, the brand name is WB140HMS, and its density is 0.905g / cm 3 (@23°C), the melt index is 2.1g / 10min (@230°C / 2.16kg). The mesh number of PTFE solid powder is 100 mesh. The mesh number of flake graphite is 1000 mesh. Both supercritical carbon dioxide and nitrogen are 99.9% pure. The addition amount of above-mentioned each raw material is shown in table 1.

[0045] Table 1

[0046] components PP PTFE flake graphite supercritical carbon dioxide supercritical nitrogen Added amount / mass percentage margin 3.0 3.0 8.0 0.15

[0047] The above-mentioned raw materials in this example are used to prepare polytetrafluoroethylene and flake graphite coupled modified low-density polypropylene foam. In the preparation method, the twin-screw temperature is set at 180°C; the barrel temperature of the twin-screw extruder is changed from the Until the extrusion port is set to 60°C-175°C-190...

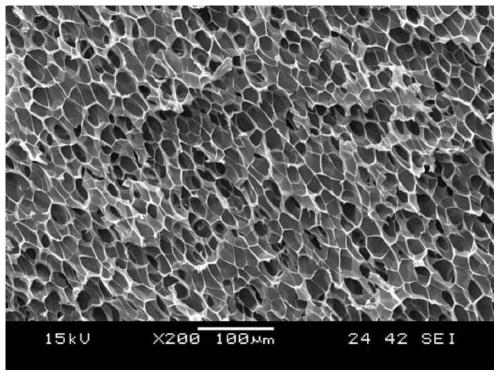

no. 2 example

[0050] Raw materials include: random copolymer polypropylene produced by Saudi Basic Industries Corporation (SABIC) with a density of 0.905 g / cm 3 (@23°C), the melt index is 1.7g / 10min (@230°C / 2.16kg). The mesh number of PTFE solid powder is 800 mesh. The mesh number of flake graphite is 5000 mesh. Both supercritical carbon dioxide and nitrogen are 99.9% pure. The addition amount of above-mentioned each raw material is shown in Table 2.

[0051] Table 2

[0052] components PP PTFE flake graphite supercritical carbon dioxide supercritical nitrogen Added amount / mass percentage margin 8.0 10 9.0 0.25

[0053] The above-mentioned raw materials in this example were used to prepare polytetrafluoroethylene and flake graphite coupled modified low-density polypropylene foam. In the preparation method, the twin-screw temperature was set at 200°C; the barrel temperature of the twin-screw extruder was changed from the Until the extrusion port is seq...

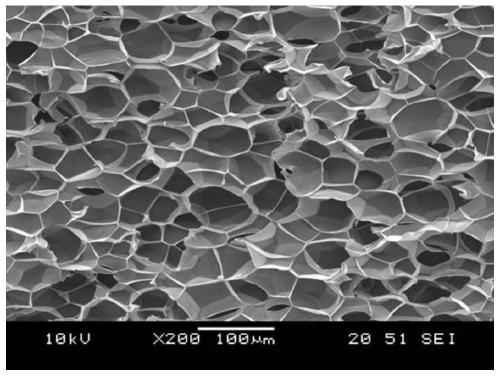

no. 3 example

[0056] Raw materials include: isotactic polypropylene produced by Japan Polypropylene Group, with a density of 0.905g / cm 3 (@23°C), the melt index is 5.0g / 10min (@230°C / 2.16kg). The mesh number of PTFE solid powder is 1500 mesh. The mesh number of flake graphite is 10000 mesh. Both supercritical carbon dioxide and nitrogen are 99.9% pure. The addition amount of above-mentioned each raw material is shown in Table 3.

[0057] table 3

[0058] components PP PTFE flake graphite supercritical carbon dioxide supercritical nitrogen Added amount / mass percentage margin 3.0 20.0 3.0 0.5

[0059] The above-mentioned raw materials in this example were used to prepare polytetrafluoroethylene and flake graphite coupling modified low-density polypropylene foam. In the preparation method, the twin-screw temperature was set at 220°C; the barrel temperature of the twin-screw extruder was changed from the hopper Until the extrusion port is set to 60°C-180°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com