Low-density polypropylene bead foam as well as preparation method and application thereof

A technology of low-density polypropylene and beads, which is applied in the field of extruding and foaming low-density polypropylene bead foam, can solve problems such as poor product uniformity, low production efficiency, and unstable process, and achieve improved foaming effect and high Effect of porosity and uniform appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

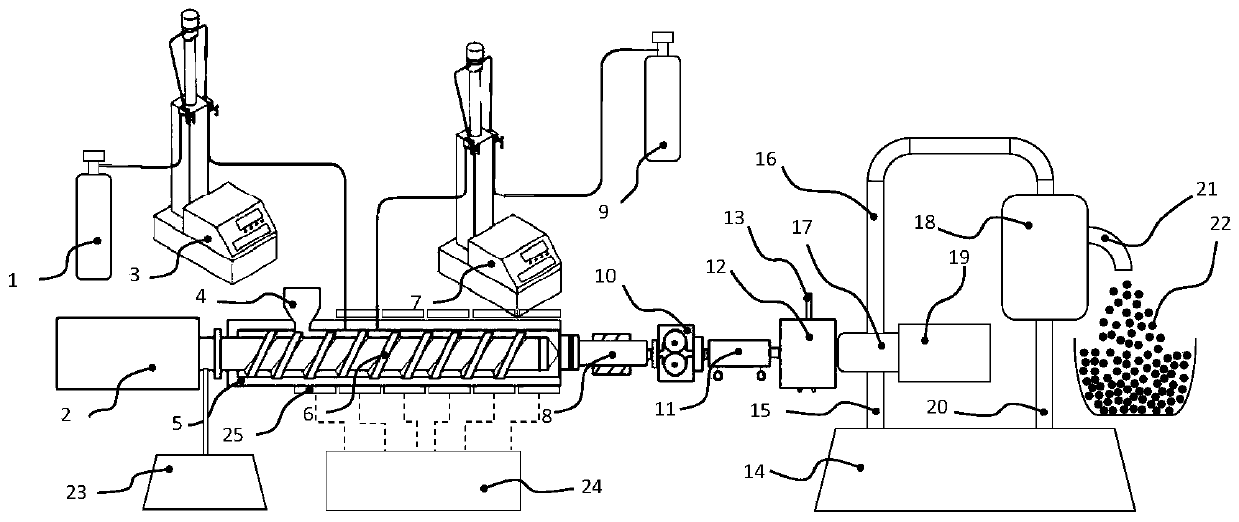

Embodiment 1

[0040] Based on the prior application of the present invention (CN 109228003A), the present invention further improves the preparation raw materials of bead foam, and obtains bead foam with better performance. In this embodiment, a feasible processing method is provided. as attached figure 1 As shown, the device for preparing PP bead foam by extrusion foaming used in Examples 2 to 4 below includes an extrusion mixing unit, a supercritical fluid injection unit, a static mixing unit, a gear pump, a melt cooler, an extrusion It is composed of die head, underwater pelletizing system, etc. Among them, the extrusion mixing unit, static mixing unit 8, gear pump 10, melt cooler 11, extrusion die head 12, underwater pelletizing system, etc. are connected in series in sequence, and the supercritical fluid injection unit is connected with the extrusion unit through pipelines. The air injection holes on the barrel of the mixing unit are connected together.

[0041] The main body of the...

Embodiment 2

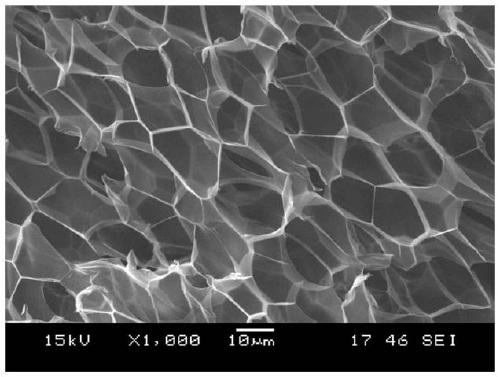

[0049] The raw material is high melt strength PP produced by Borealis, the brand name is WB140HMS, and its density is 0.905g / cm 3 (@23°C), the melt index is 2.1g / 10min (@230°C / 2.16kg); the mesh of UHMWPE solid powder is 100 mesh, and the addition amount is 5.0% by weight; the added nano-carbon material is multi-walled carbon Nanotube, its addition amount is 0.25% weight fraction; Supercritical fluid I is the carbon dioxide of purity 99.9%, supercritical fluid II is the nitrogen of purity 99.5%; The injection amount of carbon dioxide is 4.5% weight fraction, and the injection amount of nitrogen is 0.3 % weight fraction.

[0050] The twin-screw temperature is set at 180°C; the barrel temperature of the twin-screw extruder is 60°C–160°C–180°C–200°C–200°C–200°C–190°C–190°C–190°C from the hopper to the extrusion port –180°C–175°C–175°C, the screw speed is 25 rpm; the temperature of the static mixer is set to 150°C; the control pressure of the gear pump is set to 10.5MPa, and the t...

Embodiment 3

[0053] The raw material is random copolymerized polypropylene produced by Saudi Basic Industries Corporation (SABIC), and its density is 0.905g / cm 3 (@23°C), the melt index is 1.7g / 10min (@230°C / 2.16kg); the mesh number of UHMWPE solid powder is 1000 mesh, and the addition amount is 15% by weight; the added nano-carbon material is graphene, Its addition is 0.5% by weight; supercritical fluid I is carbon dioxide with a purity of 99.9%, and supercritical fluid II is nitrogen with a purity of 99.5%; the injection amount of carbon dioxide is 8% by weight, and the injection amount of nitrogen is 0.25% by weight .

[0054] The twin-screw temperature is set at 200°C; the barrel temperature of the twin-screw extruder is 60°C–160°C–180°C–200°C–200°C–200°C–200°C–200°C–200°C from the hopper to the extrusion port –190°C–180°C–180°C, the screw speed is 50 rpm; the temperature of the static mixer is set to 155°C; the control pressure of the gear pump is set to 14MPa, and the temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com