Method for treating sludge and sewage by using modified red mud and modified steel slag

A modification and red mud technology, applied in the treatment of sewage or sludge, and the field of wastewater, can solve the problems of difficult sludge treatment and low utilization rate, and achieve the effect of efficient co-processing and efficient recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

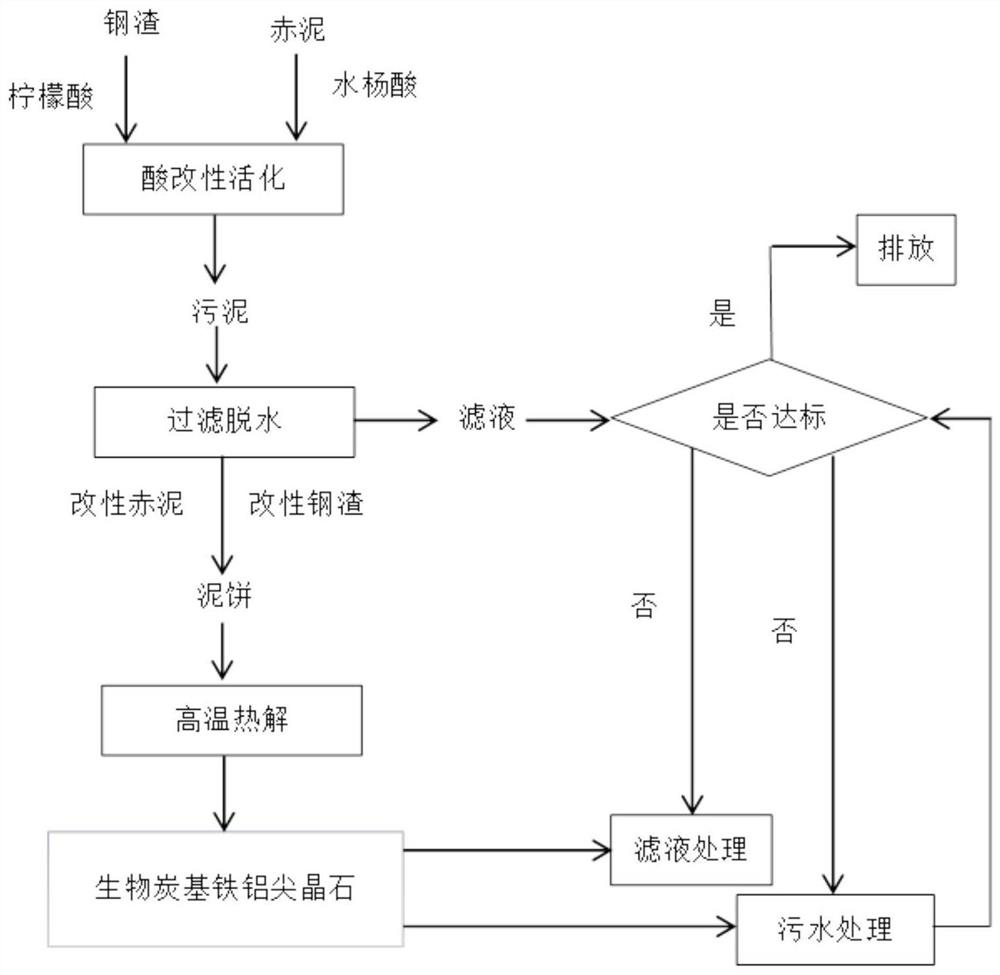

[0050] This embodiment provides a method of using red mud and steel slag to condition sludge and prepare biochar-based iron-aluminum spinel to treat sewage, such as figure 1 As shown, the method specifically includes the following steps:

[0051] S1. Add 500 g of red mud to 1 L of salicylic acid solution with a concentration of 0.034 mol / L, and soak for 8 hours. Dry the soaked red mud at 60-80°C; take 500g of steel slag and add it to 1L of citric acid solution with a concentration of 0.034mol / L, and soak for 8 hours. Dry the soaked red mud at 60-80°C;

[0052] S2. The dried modified red mud and modified steel slag are sent to a ball mill at a mass ratio of 2:1 for mixed grinding, and the mixed grinding time is 1 hour. The mixed and ground sample was sieved through a 100-mesh sieve, and the treated mixed and ground sample was recorded as #1 mixed and ground sample. Add the above-mentioned mixed grinding sample #1 to the sludge with a moisture content of 95%, and the mass rat...

Embodiment 2

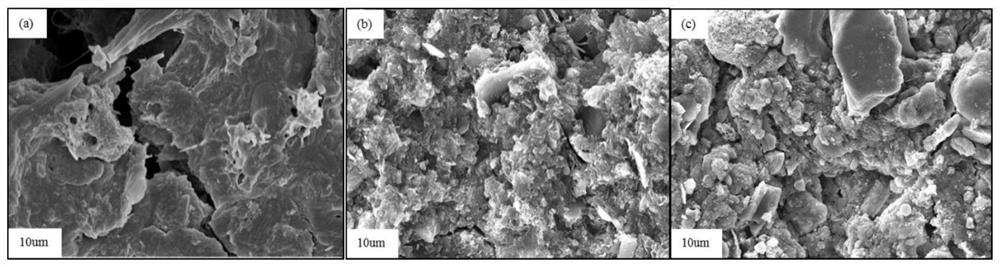

[0056] Steps S1-S2 of this example are the same as those in Example 1, except that the mass ratio of modified red mud and modified steel slag in step S2 is 1:1, and the obtained mixed grinding sample is recorded as #2 mixed grinding sample, The moisture content of the mud cake after dehydration was detected to be 53.17%. Scanning electron microscope was used to analyze the microscopic morphology of the sludge dewatered cake conditioned by #2 mixed grinding sample. The obtained SEM image is as follows figure 2 (c) shown. figure 2 The middle picture (a) is the untreated raw sludge, which was obtained by figure 2 It can be seen that figure 2 After the sludge in (b) and 2(c) is conditioned by modified red mud and modified steel slag, the floc structure of the original sludge is destroyed, forming a large particle structure, and some irregular block structures appear. Acting as a skeleton structure during the dehydration process, which is conducive to the removal of water; ...

Embodiment 3

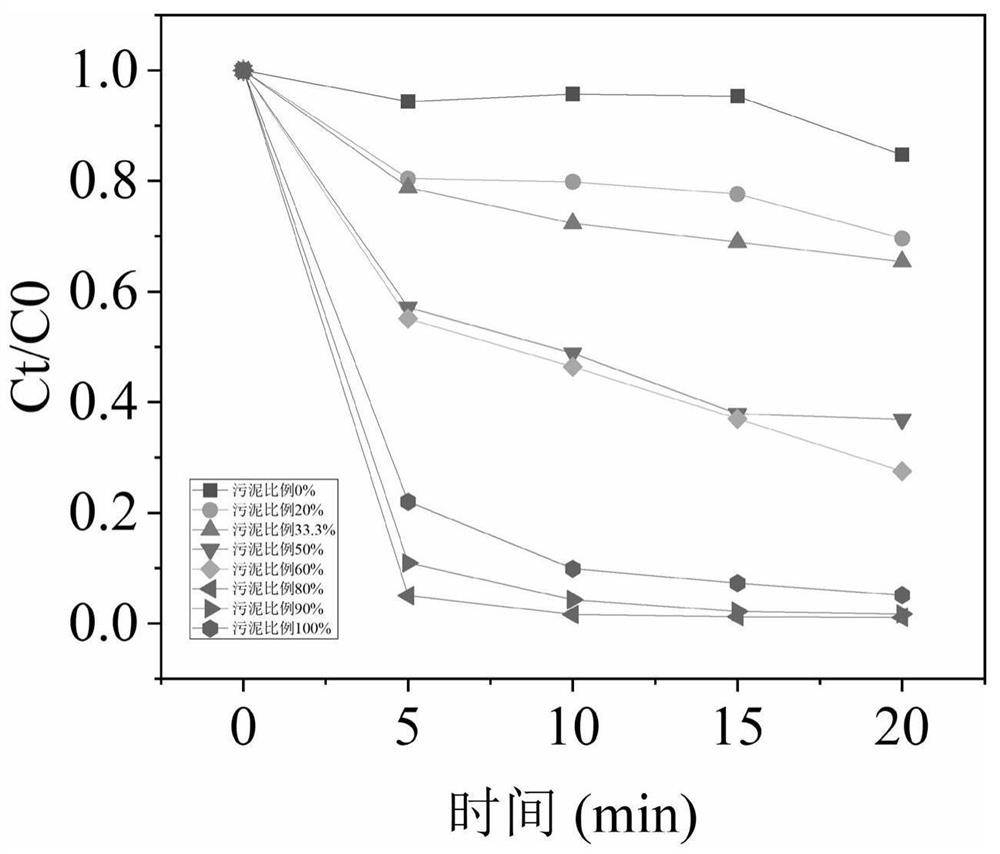

[0060] The steps of this example are the same as those of Example 2, except that the percentage of the dry weight of the sludge to the mass of the mixture system in step S3 is 90%. The removal rate of pollutants such as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com