Colored and opaque glass-ceramic(s), associated colorable and ceramable glass(es), and associated process(es)

A ceramization, glass technology, used in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as damage to the internal/electronic components of portable computing devices, user dissatisfaction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-40

[0106] Examples 1-40: Exemplary precursor glasses listed in Table I-A (most of which are tintable and ceramizable glass compositions) were prepared by introducing about 2200 g of suitable batch raw materials into platinum crucible to obtain a total of 2000 g after melting. The crucible is then placed in a furnace which is anywhere form about room temperature at about 1400°C. Use a melt cycle as follows:

[0107] 120 minutes to 1600°C; and

[0108] 1600°C, 30 minutes.

[0109] Table I-A

[0110]

[0111]

[0112] Table I-A continued

[0113]

[0114]

[0115] Table I-B

[0116]

[0117]

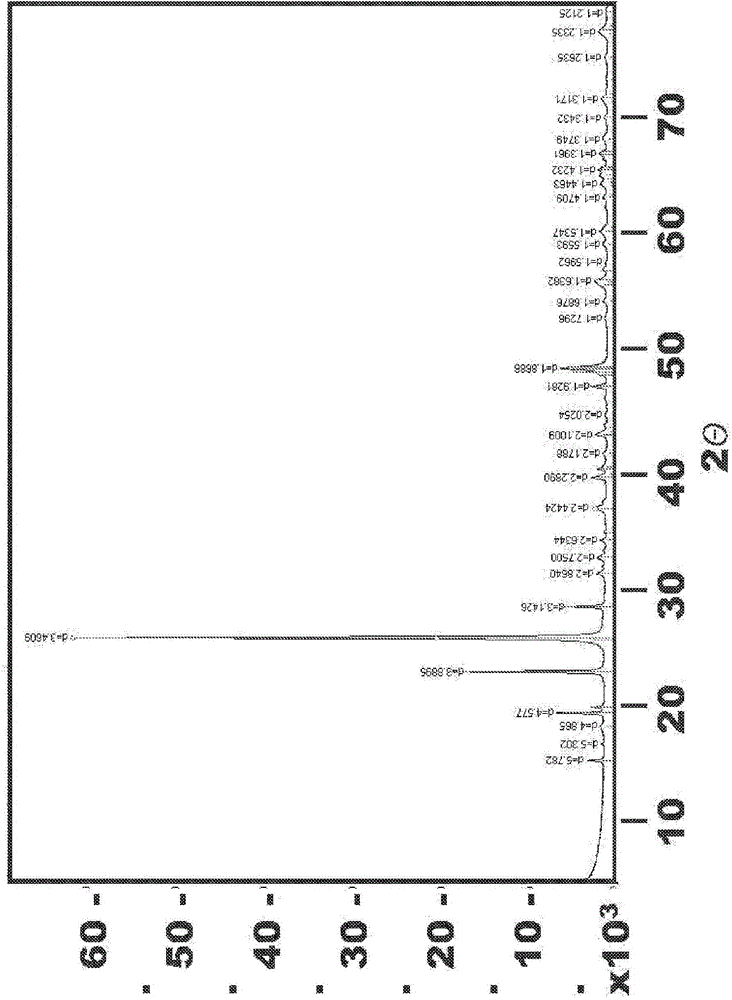

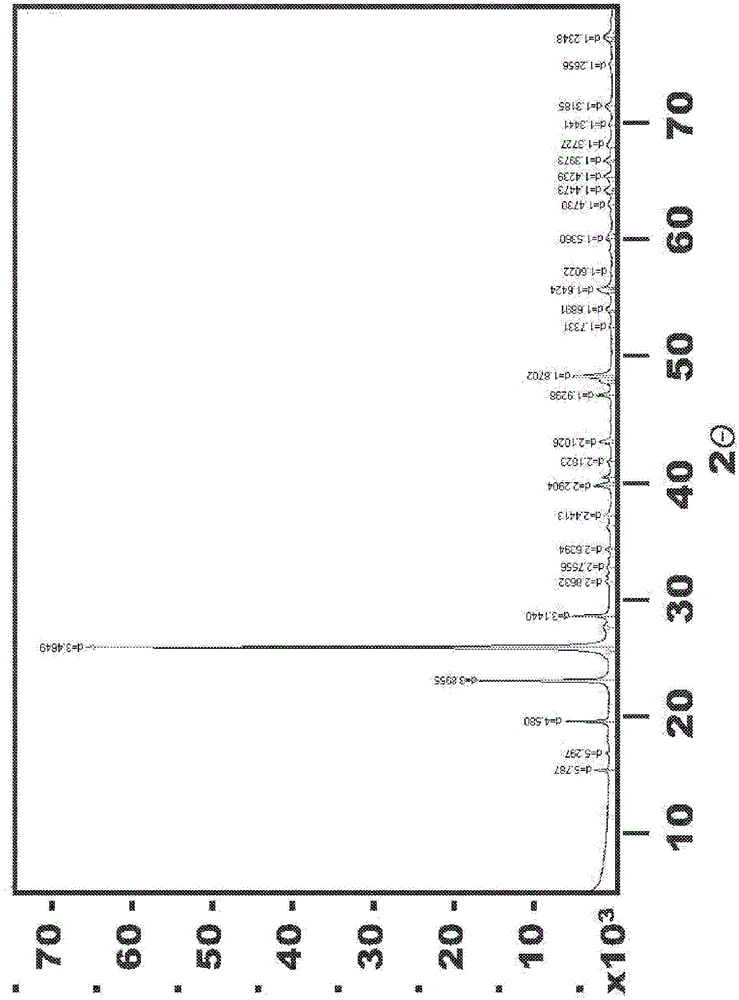

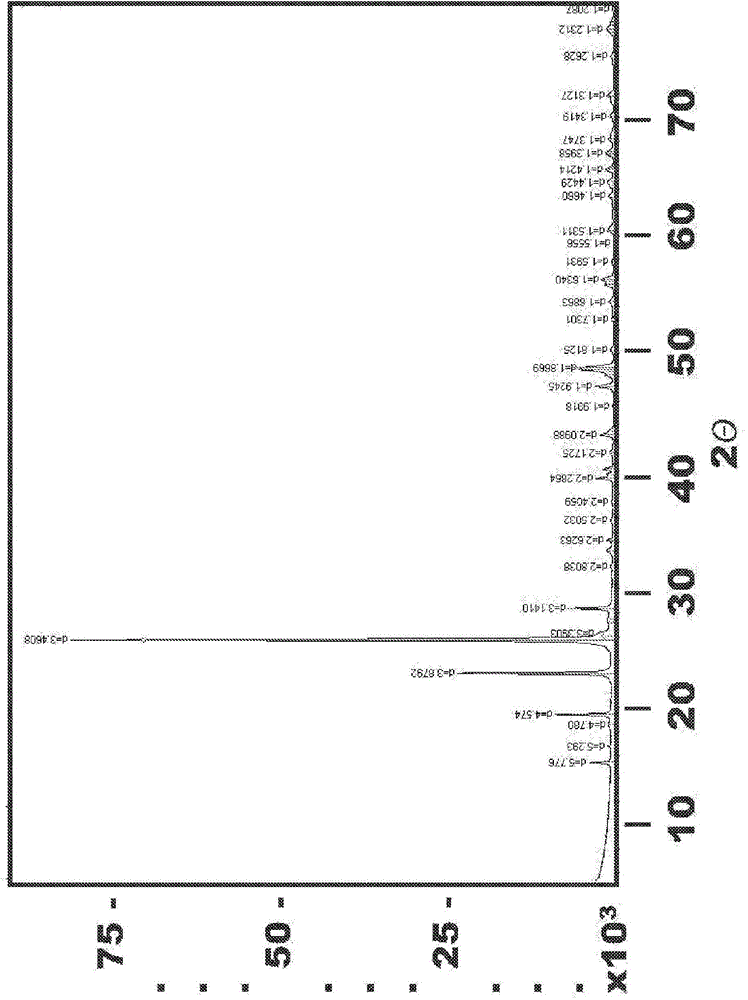

[0118] BS = β-spodumene ss, BQ = β-quartz ss, SP = spinel ss (iron spinel + gahnite), PB = brookite, RU = rutile,

[0119] MZP = magnesium zinc phosphate, IMT = iron manganese titanate, NA = not available, ND = not sure

[0120]

[0121]

[0122] BS = β-spodumene ss, BQ = β-quartz ss, SP = spinel ss (iron spinel + zinc spinel),

[0123] PB = brookite, RU = rutil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Knoop hardness | aaaaa | aaaaa |

| Knoop hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com