Hercynite synthesis method

A technology of iron-aluminum spinel and synthesis method, applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve the problems of reduced thermal efficiency, unstable system, etc., and achieves low cost, simple preparation process, and high yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Prepare iron-aluminum spinel according to the following steps:

[0018] ① Mix 0.01 mol ferric nitrate, 0.02 mol aluminum nitrate, 0.05 mol urea, 0.015 mol diethylamine hydrochloride, and heat to 100°C to form a liquid;

[0019] ②Continue to heat the liquid mentioned in step ① to 200°C to burn the liquid, which will produce a large amount of smoke and open flame, releasing a large amount of heat;

[0020] ③ Collect the solid produced after complete combustion in step ②, cool and grind to obtain a gray-black powder. XRD results show that the powder is pure iron-aluminum spinel, which is designated as sample A.

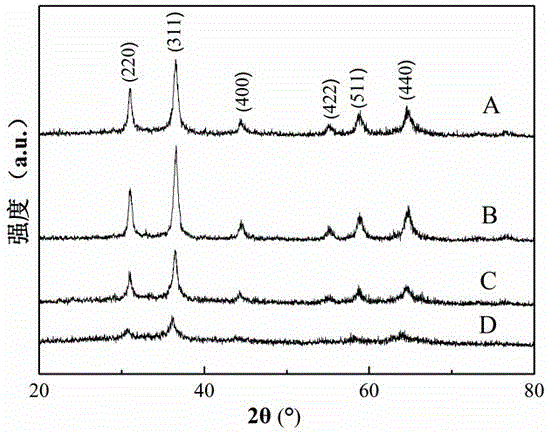

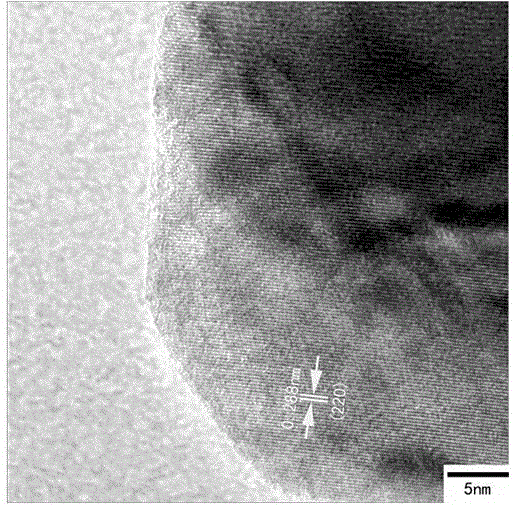

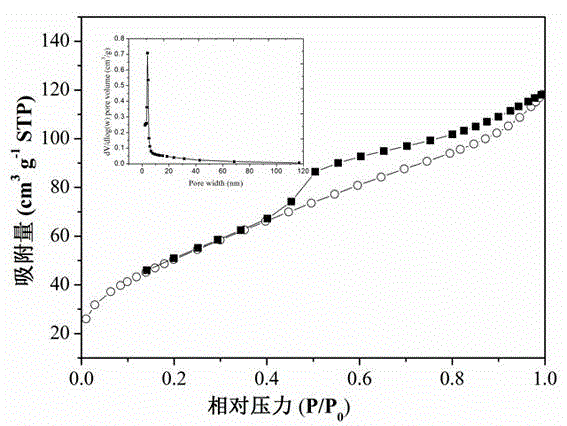

[0021] Carry out XRD and HRTEM, FESEM and N to above-mentioned white powder respectively 2 Adsorption and desorption test, the test spectrum is as follows Figure 1 to Figure 4 shown. Depend on figure 1 It can be seen that the 2θ angles at 30.92°, 36.22°, 44.30°, 55.06°, 58.26°, and 64.28° in the XRD pattern correspond to (220), (311), (400), (422), (511), (4...

Embodiment 2

[0023] Prepare iron-aluminum spinel according to the following steps:

[0024] ① Mix 0.01 mol ferric nitrate, 0.02 mol aluminum nitrate, 0.05 mol urea, 0.01 mol diethylamine hydrochloride, and heat to 150°C to form a liquid;

[0025] ②Continue to heat the liquid mentioned in step ① to 200°C to burn the liquid, which will produce a large amount of smoke and open flame, releasing a large amount of heat;

[0026] ③ Collect the solid produced after complete combustion in step ②, cool and grind to obtain a gray-black powder. XRD results show that the powder is pure iron-aluminum spinel, which is designated as sample B.

[0027] Carry out XRD and N to the above-mentioned white powder respectively 2 Adsorption and desorption test, XRD pattern as figure 1 As shown in sample B, it presents a pure iron-aluminum spinel structure; N 2 Adsorption and desorption tests show that the specific surface area of the powder is 116.07 m 2 / g, the average pore diameter is 3.81nm, and the total...

Embodiment 3

[0029] Prepare iron-aluminum spinel according to the following steps:

[0030] ① Mix 0.01 mol ferric nitrate, 0.02 mol aluminum nitrate, 0.05 mol urea, 0.008 mol diethylamine hydrochloride, heat to 160°C to form a liquid;

[0031] ②Continue to heat the liquid mentioned in step ① to 240°C, the liquid will burn, and the combustion will produce a large amount of smoke, and produce an open flame, releasing a large amount of heat;

[0032] ③ Collect the solid produced after complete combustion in step ②, cool and grind to obtain a gray-black powder. XRD results show that the powder is pure iron-aluminum spinel, which is designated as sample C.

[0033] Carry out XRD and N to the above-mentioned white powder respectively 2 Adsorption and desorption test, XRD pattern as figure 1 As shown in sample C, it presents a pure iron-aluminum spinel structure; N 2 Adsorption and desorption tests show that the specific surface area of the powder is 143.59 m 2 / g, the average pore diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com