Magnesia-hercynite brick used by high temperature zone of cement kiln and use method thereof

A technology of magnesia-iron-aluminum spinel and iron-aluminum spinel, which is applied in the field of magnesia-iron-aluminum spinel bricks in the high-temperature zone of cement kilns, can solve the problems that the comprehensive performance is not as good as that of magnesia-chrome bricks, and achieve the effect of optimal configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

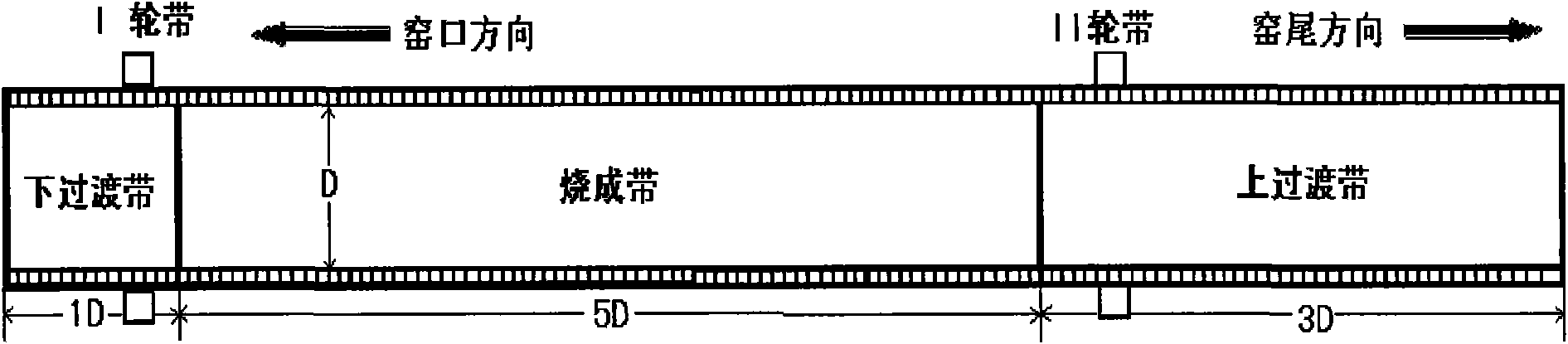

[0017] Large dry process cement kiln A, precalciner kiln type, specifications The designed output is 5000T / D, the fuel is bituminous coal, and the kiln operation rate is >95%. The configuration of chrome-free refractory bricks for kiln A is shown in Table 3.

[0018] Table 3 Kiln A chrome-free refractory brick configuration

[0019] Application area

[0020] The firing zone of kiln A adopts magnesia-iron-aluminum spinel bricks with excellent performance of hanging kiln skin and thermal shock stability. The kiln skin in the transition zone is not easy to hang stably, but due to the high operating rate of the kiln and the stable kiln condition, it is not easy to get big balls in the kiln. The mechanical wear requirements of the refractory bricks used in the transition zone are relatively low. Comprehensive consideration, the overall thermal shock performance of the transition zone is better The new type of magnesia-alumina spinel bricks, the alumina content is gene...

Embodiment 2

[0022] Large dry process cement kiln B, precalciner kiln type, specifications The designed output is 2500T / D, the fuel is bituminous coal, and the kiln operation rate is >90%. The configuration of chrome-free refractory bricks for kiln B is shown in Table 4.

[0023] Table 4 Kiln B chrome-free refractory brick configuration

[0024] Application area

lower transition zone

Firing zone

upper transition zone

Chrome-free brick

Silica Brick / New Magnesium Aluminum Spinel

the brick

New magnesia alumina spinel brick / Simo

the brick

[0025] The firing zone of kiln B adopts magnesia-iron-aluminum spinel bricks with excellent performance of hanging kiln skin and thermal shock stability. The kiln skin in the transition zone is not easy to hang stably, but because the kiln operating rate is lower than that of kiln A, the stability of the kiln condition decreases, and the kiln is prone to large balls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com