Periclase-pleonaste and hercynite/forsterite composite brick

A technology of iron-aluminum spinel and forsterite, which is applied in the field of refractory materials, can solve the problems that the thermal conductivity of materials cannot be effectively reduced, the energy-saving effect of the firing zone is not significant, and the heat insulation effect of composite bricks is poor, so as to solve the problems of high-strength With low thermal conductivity, increase the strength/thermal conductivity ratio, and the effect of being easy to stick to the kiln skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

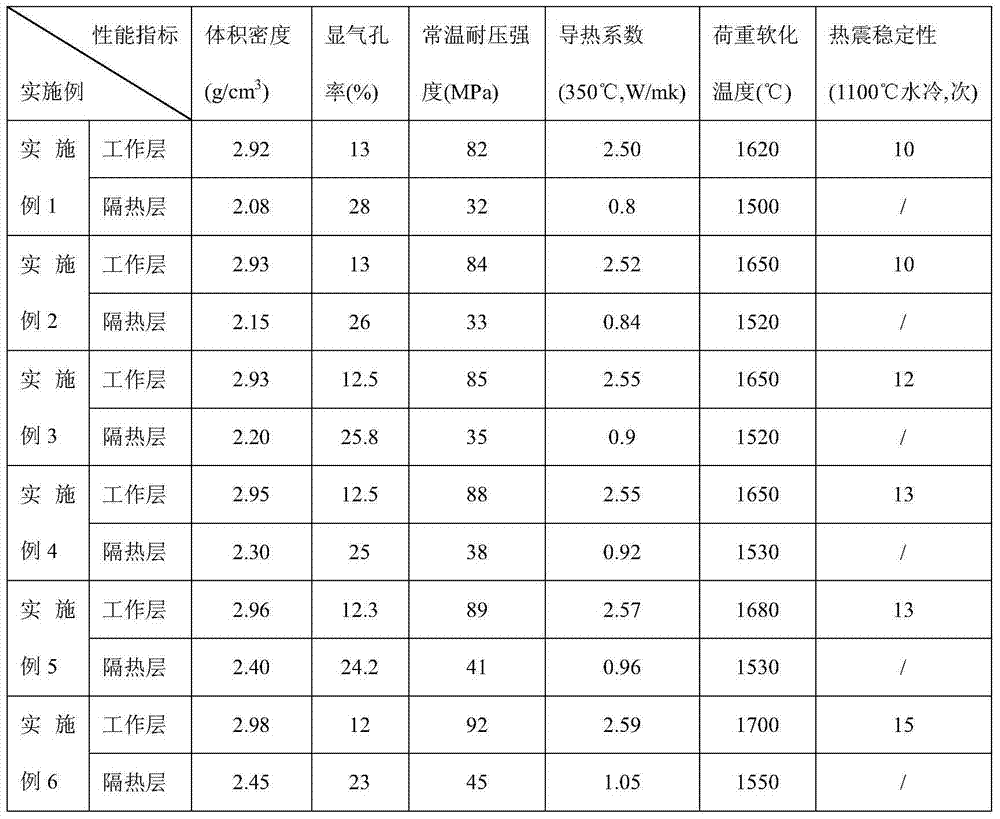

Embodiment 1~6

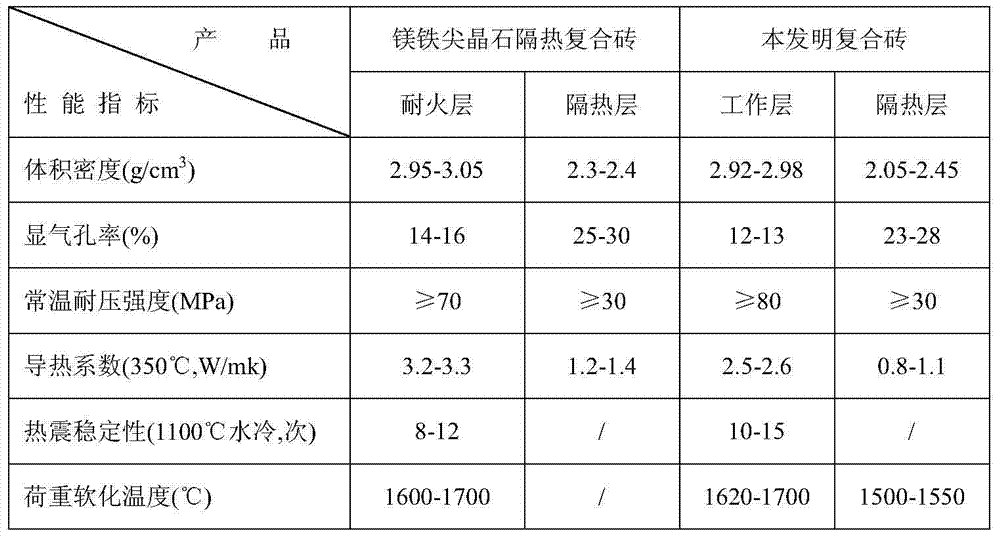

[0032] Table 2 The raw material composition of the working layer and the thermal insulation layer of the periclase-mafic iron aluminum spinel / forsterite composite bricks in Examples 1 to 6

[0033]

[0034] Note: 1) The concentration of the magnesium lignosulfonate solution described in Examples 1 and 2 is 1.05g / cm 3 , The chemical composition of the magnesium iron sand is: MgO 85wt%, Fe 2 O 3 14wt%, the balance being impurities, the medium-weight synthetic forsterite sand refers to medium-heavy synthetic forsterite sand; 2) The concentration of the magnesium lignosulfonate solution in Example 3 is 1.25 g / cm 3 , The chemical composition of the magnesite sand is: MgO 90wt%, Fe 2 O 3 8wt%, the balance is impurities. The medium-weight synthetic forsterite sand refers to medium-light synthetic forsterite sand; 3) The concentration of the magnesium lignosulfonate solution in Examples 4 and 5 is 1.15 g / cm 3 , The chemical composition of the magnesium iron sand is: MgO 85wt%, Fe 2 O 3 10wt...

Embodiment 7

[0036] One of the preparation methods of periclase-mafic iron aluminum spinel / forsterite composite bricks described in any one of the foregoing embodiments 1 to 6 includes the following steps: (1) Preparation of working layer brick materials: press The raw material composition of the working layer prepares the raw materials, after they are evenly mixed, the water reducing agent and the binder are added, and the wet mill is used for mixing until uniform; (2) Preparation of insulation layer brick materials: prepare each raw material according to the raw material composition of the insulation layer After mixing uniformly, add polystyrene balls and binder, and mix with wet mill until uniform; (3) Forming and firing: divide the brick mold into two parts, the hot end and the cold end, with a partition plate , Add the working layer to make bricks at the hot end, add the insulation layer to make bricks at the cold end, then pull out the partition plate, press the bricks into bricks with...

Embodiment 8

[0038] The second preparation method of the periclase-mafic iron aluminum spinel / forsterite composite brick described in any one of the foregoing Examples 1 to 6 is basically the same as that of Example 7, and the difference is that the brick is made Afterwards, the bricks were dried at 120°C for 20 hours in a drying kiln, and then fired at 1500°C for 8 hours before being discharged from the kiln.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com