Magnesium-ferrum-aluminum composite spinel brick for large-scale cement kiln and preparation method thereof

A technology of magnesia-aluminum spinel and iron-aluminum spinel is applied in the field of refractory materials, which can solve problems such as pollution, and achieve the effects of simple process, long operation time and improved operation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

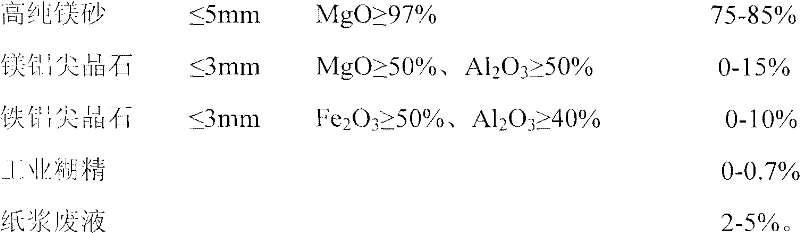

[0014] Magnesium-iron-aluminum composite spinel bricks for large cement kilns, the weight ratio of each component is:

[0015] High-purity magnesia ≤5mm MgO≥97% 80%

[0016] Magnesium aluminum spinel ≤3mm MgO≥50%, Al 2 o 3 ≥50% 15%

[0017] Fe-aluminum spinel ≤3mm FeO≥60%, Al 2 o 3 ≥40% 5%

[0018] Binding agent:

[0019] Industrial dextrin 0.7%

[0020] Pulp waste liquid 2.5%

[0021] The above raw materials are mixed according to the required ratio, and made into mud in a mixer, and molded under a pressure of 400T. After molding, the adobe is fired in a tunnel kiln or a shuttle kiln at 1500°C.

Embodiment 2

[0023] Magnesium-iron-aluminum composite spinel bricks for large cement kilns, the weight ratio of each component is:

[0024] High-purity magnesia ≤5mm MgO≥97% 85%

[0025] Magnesium aluminum spinel ≤3mm MgO≥50%, Al 2 o 3 ≥50% 5%

[0026] Fe-aluminum spinel ≤3mm FeO≥60%, Al 2 o 3 ≥40% 10%

[0027] Binding agent:

[0028] Industrial dextrin 0.5%

[0029] Pulp waste liquid 3%

[0030] The above raw materials are mixed according to the required ratio, and made into mud in a mixer, and molded under a pressure of 600T. After molding, the adobe is fired at 1600°C in a tunnel kiln or a shuttle kiln.

Embodiment 3

[0032] Magnesium-iron-aluminum composite spinel bricks for large cement kilns, the weight ratio of each component is:

[0033] High-purity magnesia ≤5mm MgO≥97% 75%

[0034] Magnesium aluminum spinel ≤3mm MgO≥50%, Al 2 o 3 ≥50% 15%

[0035] Fe-aluminum spinel ≤3mm FeO≥60%, Al 2 o 3 ≥40% 10%

[0036] Binding agent:

[0037] Industrial dextrin 0.2%

[0038] Pulp waste liquid 5%

[0039] The above raw materials are mixed according to the required ratio, and made into mud in a mixer, and molded under a pressure of 500T. After molding, the bricks are fired at 1700°C in a tunnel kiln or a shuttle kiln.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com