Method for preparing magnesia-hercynite refractory material

A technology of iron-aluminum spinel and aluminum spinel is applied in the field of preparation of magnesia-iron-aluminum spinel refractory materials, which can solve the problems of poor hydration resistance, poor kiln skin property, poor thermal shock resistance, etc. Good thermal shock resistance, easy to hang kiln skin, good corrosion resistance to cement clinker

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

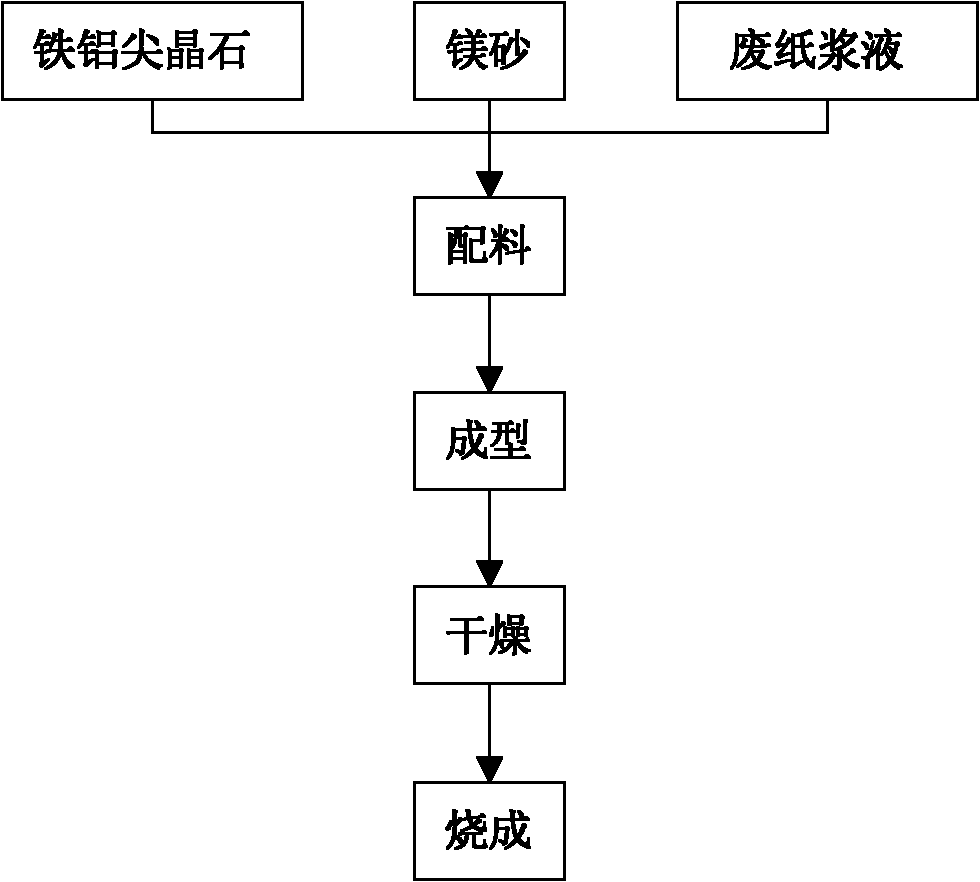

Method used

Image

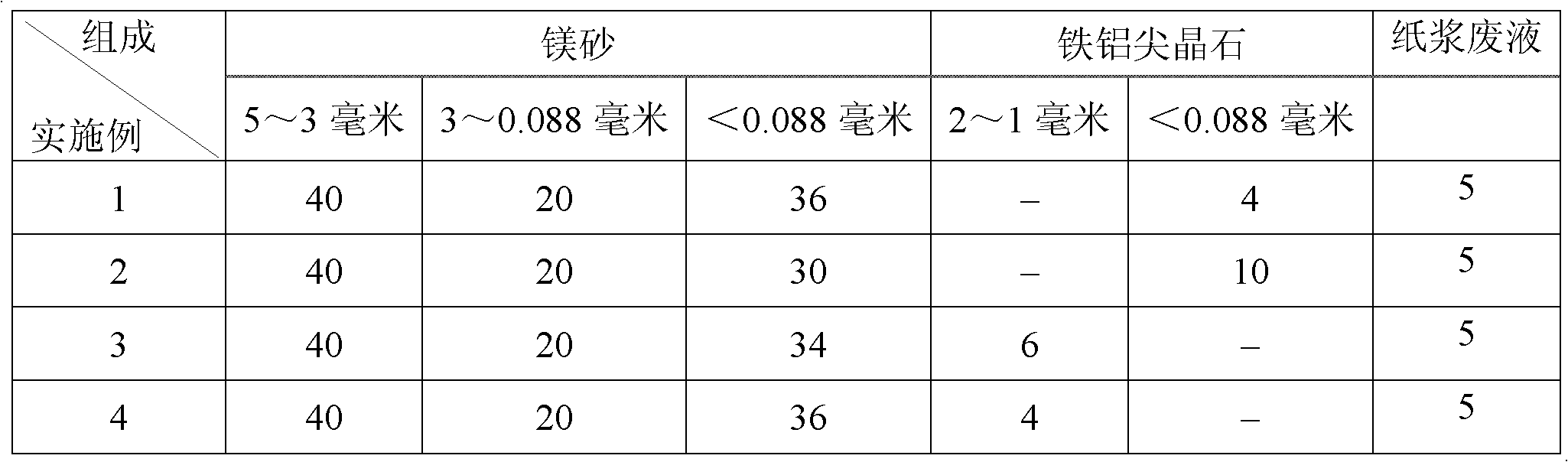

Examples

Embodiment 1

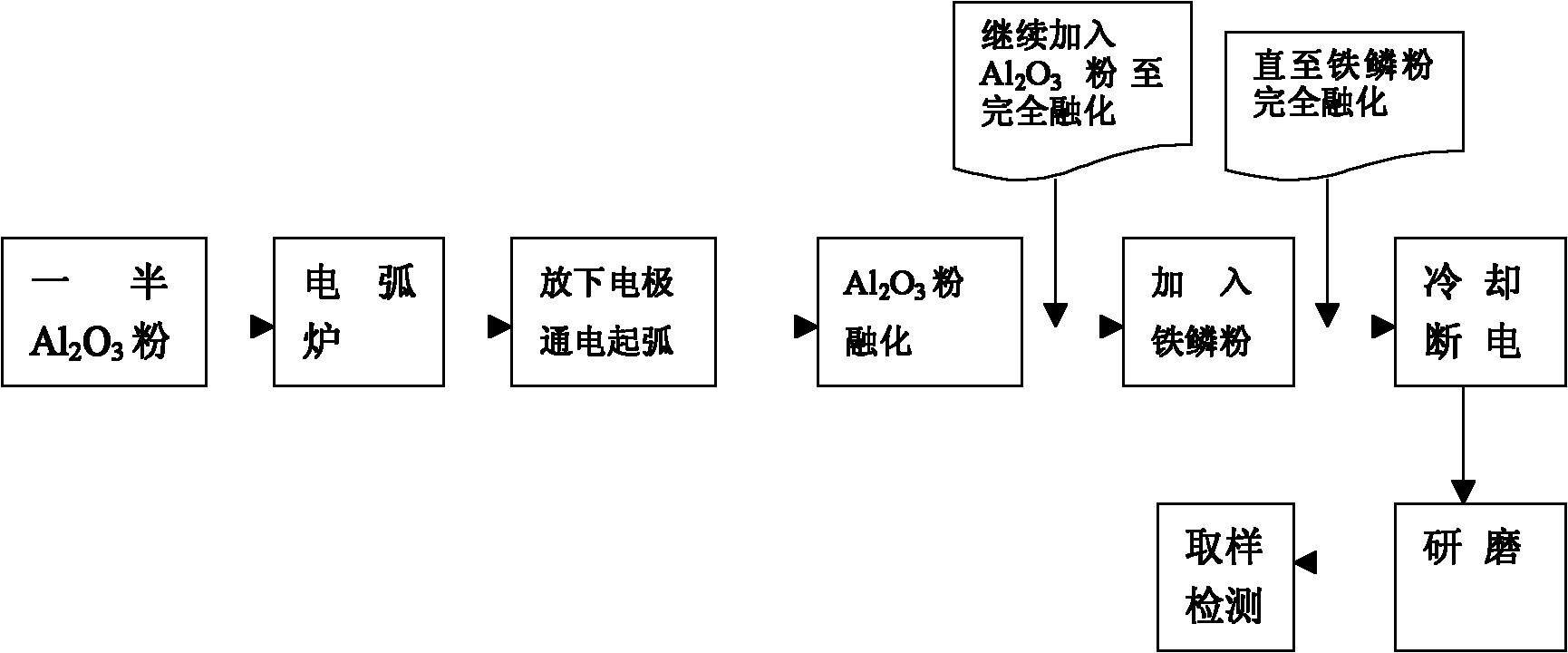

[0029] First, the iron-aluminum spinel needed for the experiment was prepared by electromelting. The steps are as follows:

[0030] by FeO and Al 2 o 3 The powder ratio (weight percent) is 40:60 and weighed FeO powder and Al 2 o 3 powder raw material, and then the weighed Al 2 o 3 Pour 50% of the powder into the electric arc furnace, and place a piece of waste paper on the surface, and place the raw materials FeO powder and Al on the waste paper. 2 o 3 10% graphite block by powder gross weight and 5% strip-shaped iron filings by raw material gross weight, put down the electrode and make it contact with the graphite block, adjust the voltage to 110 volts, and feed the electric current. After 5 minutes, a violent light and heat generation occurs, and Al 2 o 3 The powder begins to melt slowly, the deeper the electrode is immersed in the liquid, the greater the current, the farther the electrode is from the liquid surface, the longer the arc is drawn, and then the remaini...

Embodiment 2

[0033] First, the iron-aluminum spinel needed for the experiment was prepared by electromelting. The steps are as follows:

[0034] by FeO and Al 2 o 3 Powder ratio (weight percent) is 60:40 and weigh FeO powder and Al 2 o 3 powder raw material, and then the weighed Al 2 o 3 Pour 50% of the powder into the electric arc furnace, and place a piece of waste paper on the surface, and place the raw materials FeO powder and Al on the waste paper. 2 o 3 10% graphite block by powder gross weight and 5% strip-shaped iron filings by raw material gross weight, put down the electrode and make it contact with the graphite block, adjust the voltage to 120 volts, and feed the electric current. After 5 minutes, a violent light and heat generation occurs, and Al 2 o 3 The powder begins to melt slowly, the deeper the electrode is immersed in the liquid, the greater the current, the farther the electrode is from the liquid surface, the longer the arc is drawn, and then the remaining 50%...

Embodiment 3

[0037] First, the iron-aluminum spinel needed for the experiment was prepared by electromelting. The steps are as follows:

[0038] by FeO and Al 2 o 3 Powder ratio (weight percent) is 50:50 and weigh FeO powder and Al 2 o 3 powder raw material, and then the weighed Al 2 o 3 Pour 50% of the powder into the electric arc furnace, and place a piece of waste paper on the surface, and place the raw materials FeO powder and Al on the waste paper. 2 o 3 10% graphite block by powder gross weight and 5% strip-shaped iron filings by raw material gross weight, put down the electrode and make it contact with the graphite block, adjust the voltage to 120 volts, and feed the electric current. After 5 minutes, a violent light and heat generation occurs, and Al 2 o 3 The powder begins to melt slowly, the deeper the electrode is immersed in the liquid, the greater the current, the farther the electrode is from the liquid surface, the longer the arc is drawn, and then the remaining 50%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com