Single taphole blast furnace tapping channel iron storing type improving technology

A blast furnace iron tapping and iron storage technology, applied in blast furnace, blast furnace details, blast furnace parts and other directions, can solve the problem of inability to achieve rapid repair and maintenance, and achieve long service life, prolong the service life of refractory materials, and prolong the service life effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Using this plan to transform the main iron trough of a 450 cubic meter blast furnace in a steel company, the results are as follows:

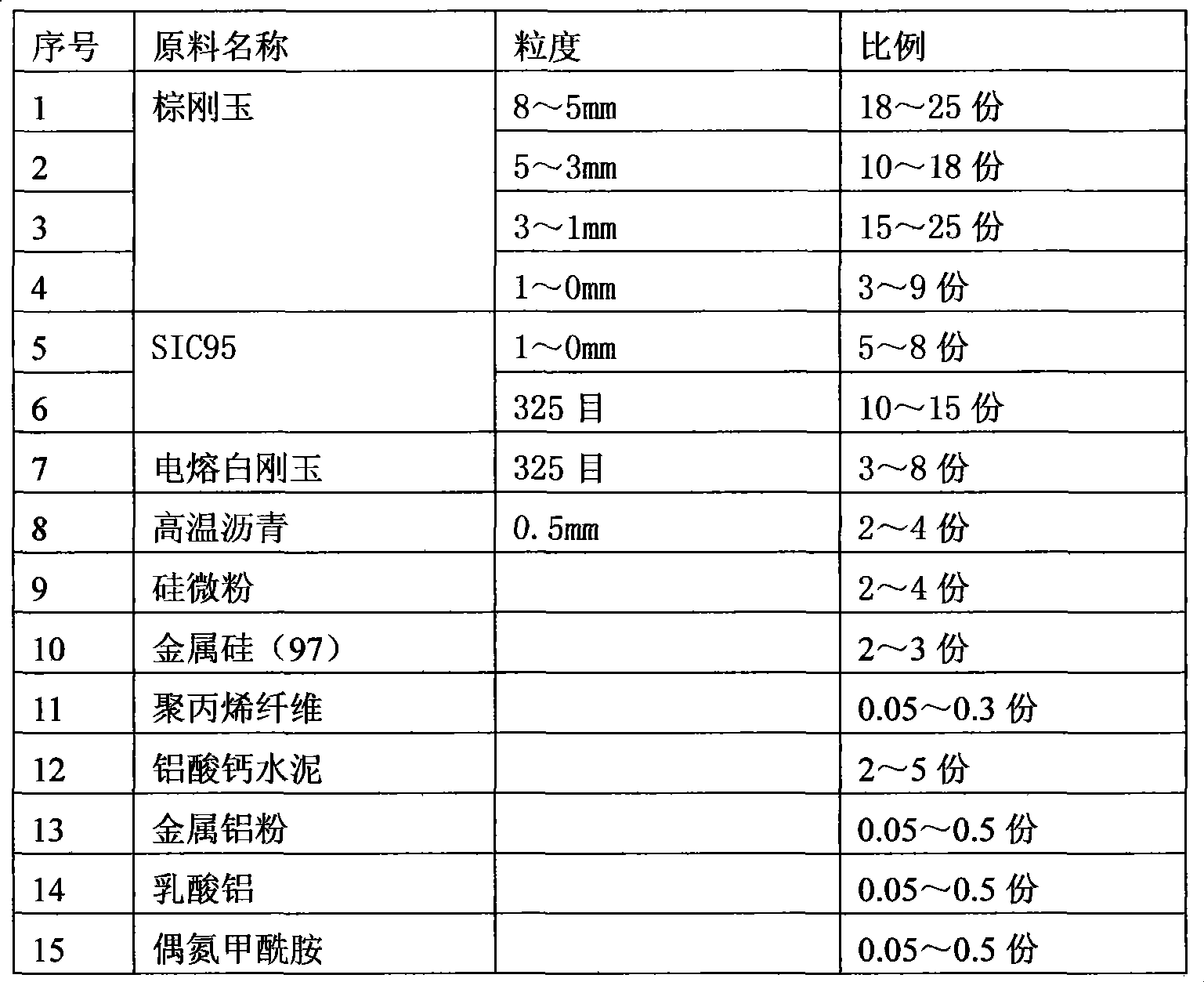

[0032] The material batching scheme is shown in the table below:

[0033]

[0034]

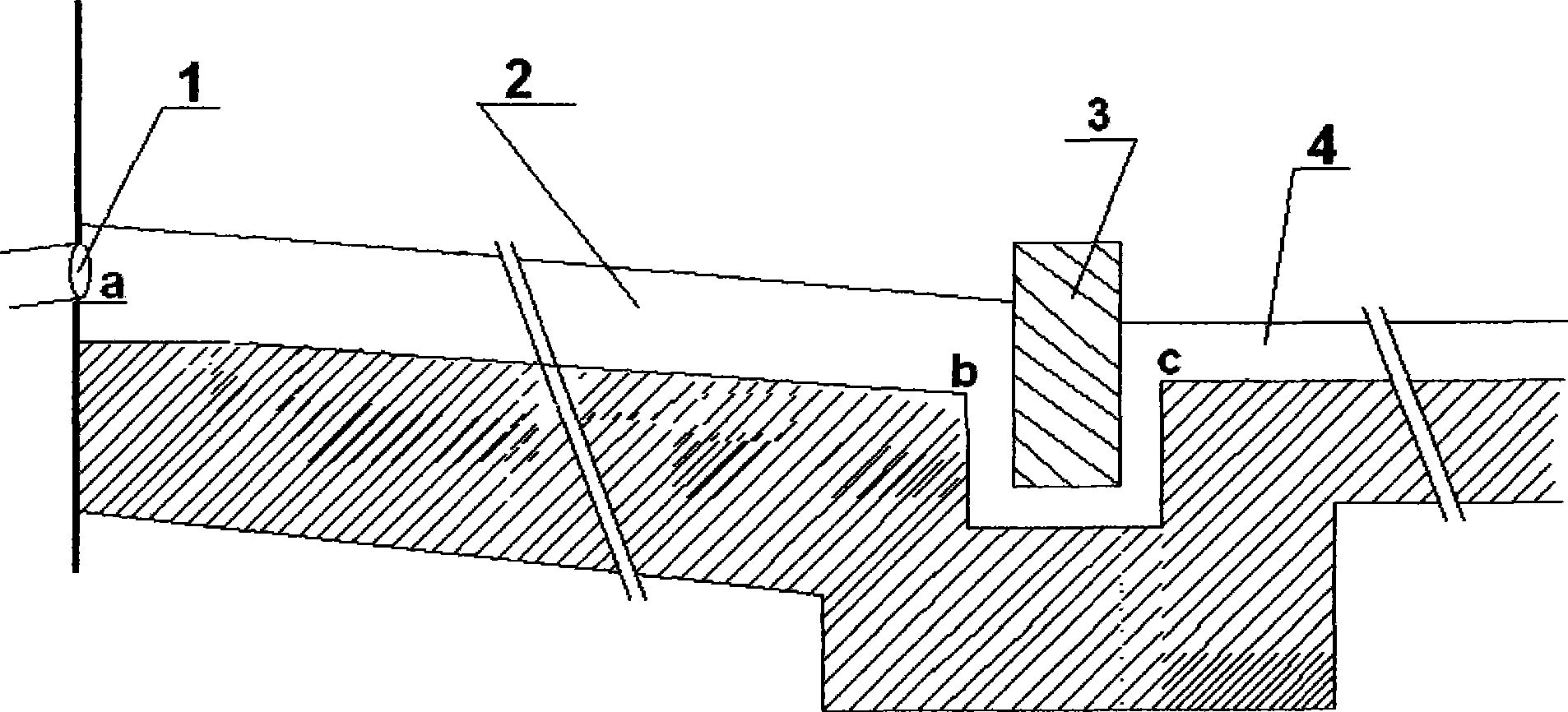

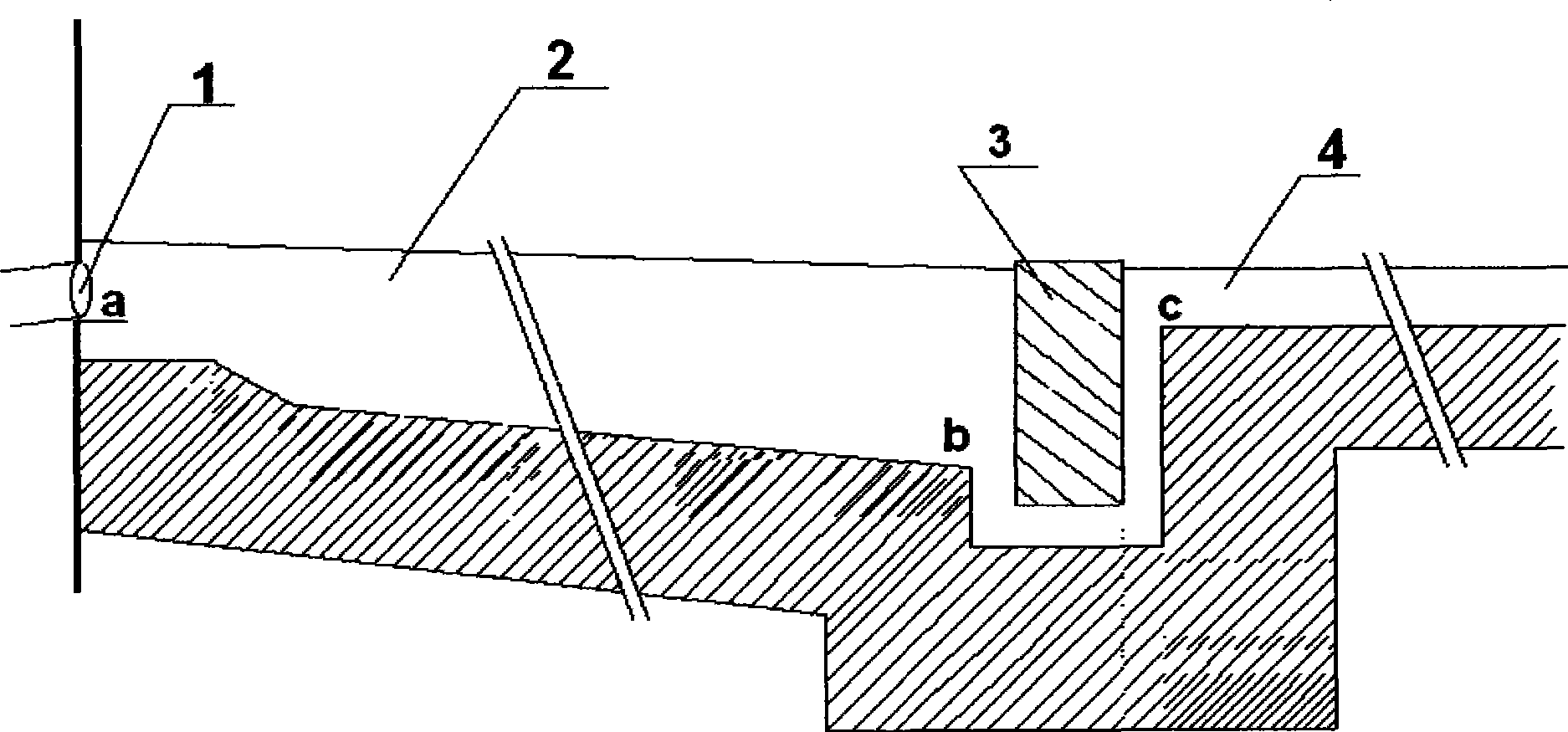

[0035] The first 15 materials in the above ingredients are mixed evenly to form a premix for later use. When using, only 6% of the dry mixture weight needs to be added to the tap water to mix and stir to form a mortar. figure 2 Structural transformation plan carried out iron storage type transformation on the 3# blast furnace iron trough of the plant.

[0036] The pouring scope includes all the main iron trenches and all the branch iron trenches. The mold is demoulded about 30 minutes after pouring, and the fire is baked immediately. The baking time for the first renovation of the iron trench was about 6 hours, and the iron began to tap after the surface turned red.

[0037] The amount of iron passing through the main ditch without repairing exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com