Refractory block and refractory wall assembly

a technology of refractory blocks and refractory walls, applied in the field of refractory arts, can solve the problems of eroding the strength of metallic panels, buckling and distortion, deterioration and failure of metallic panels, etc., and achieves the effects of improving wall structure, reducing heat transfer, and being easy to assembl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

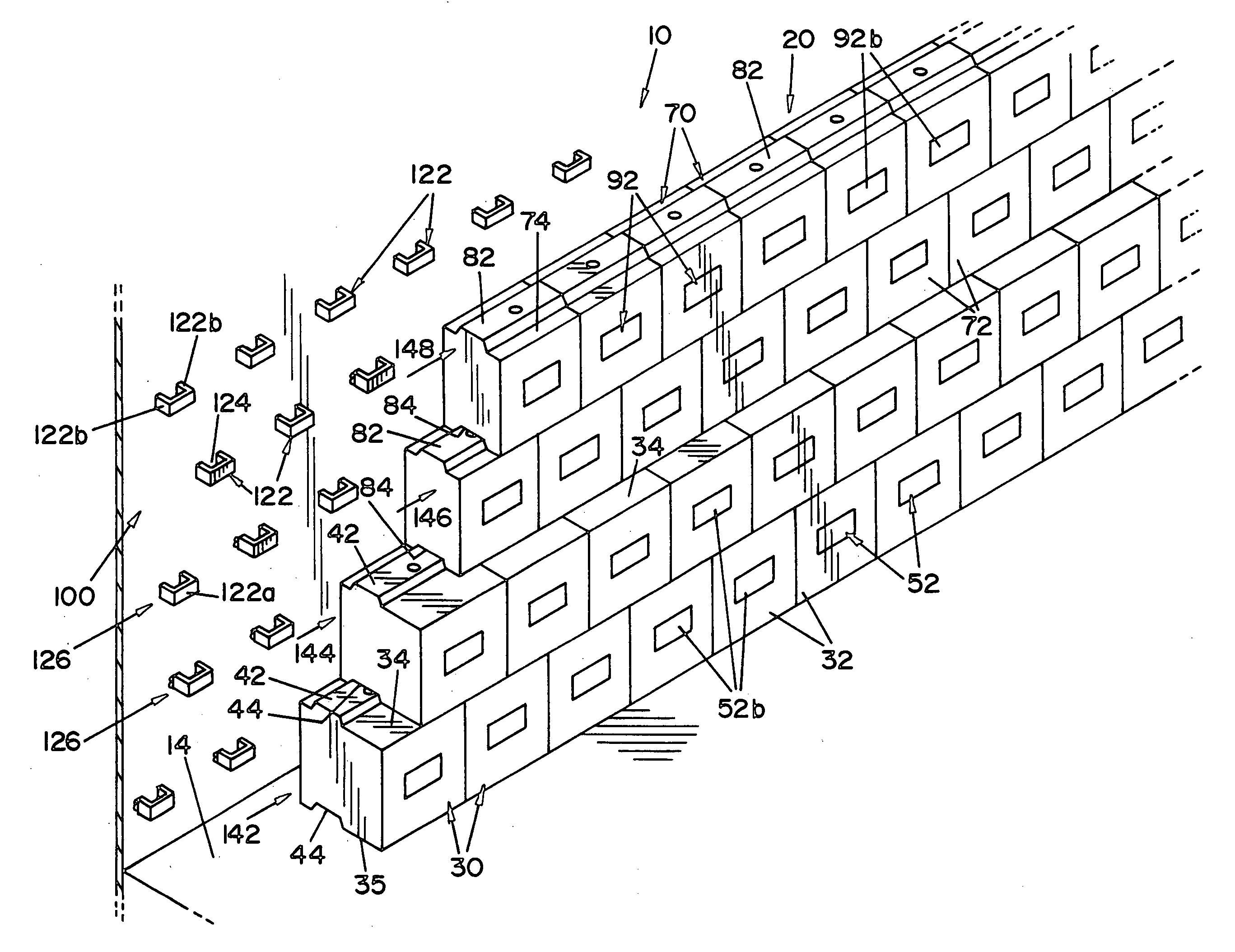

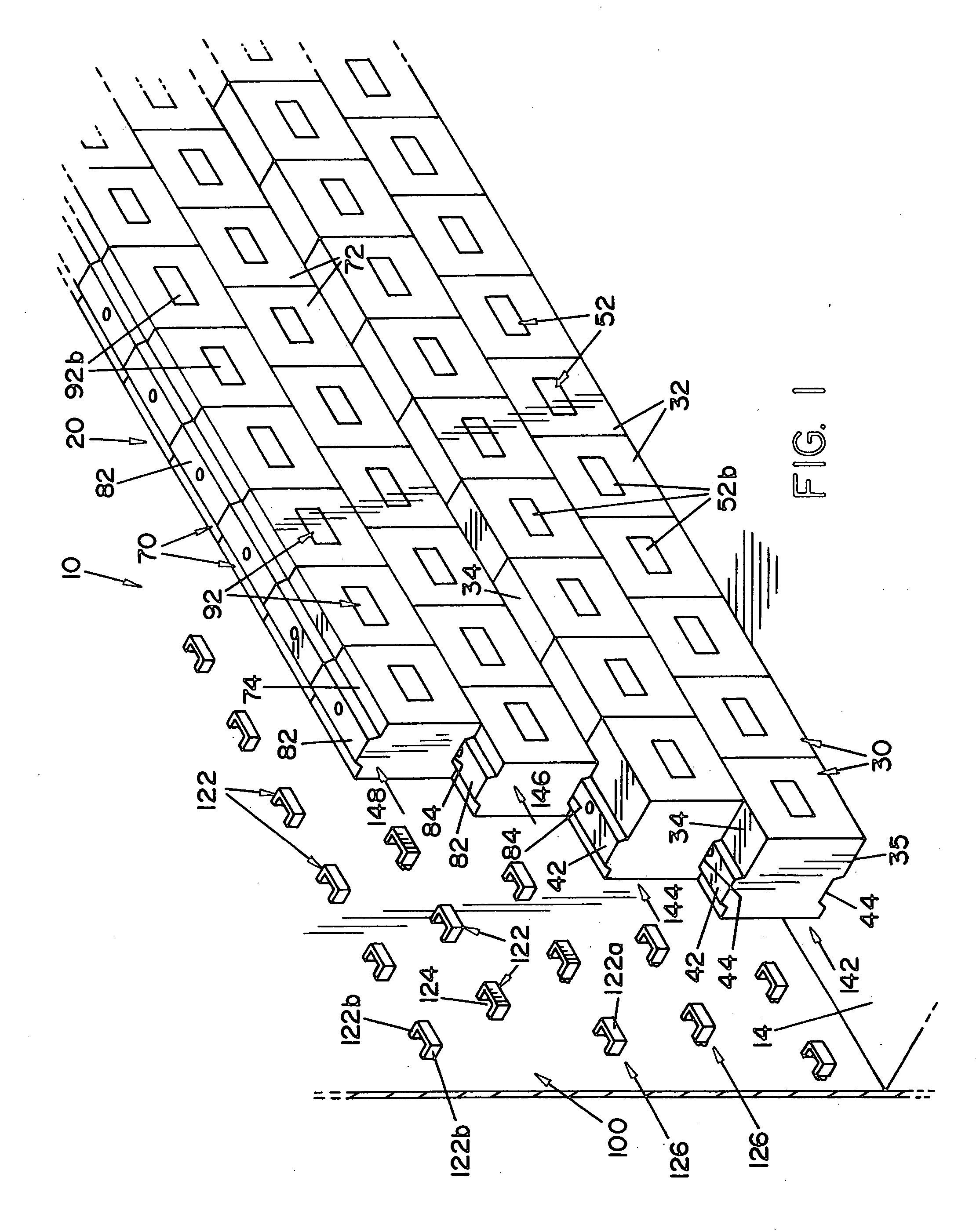

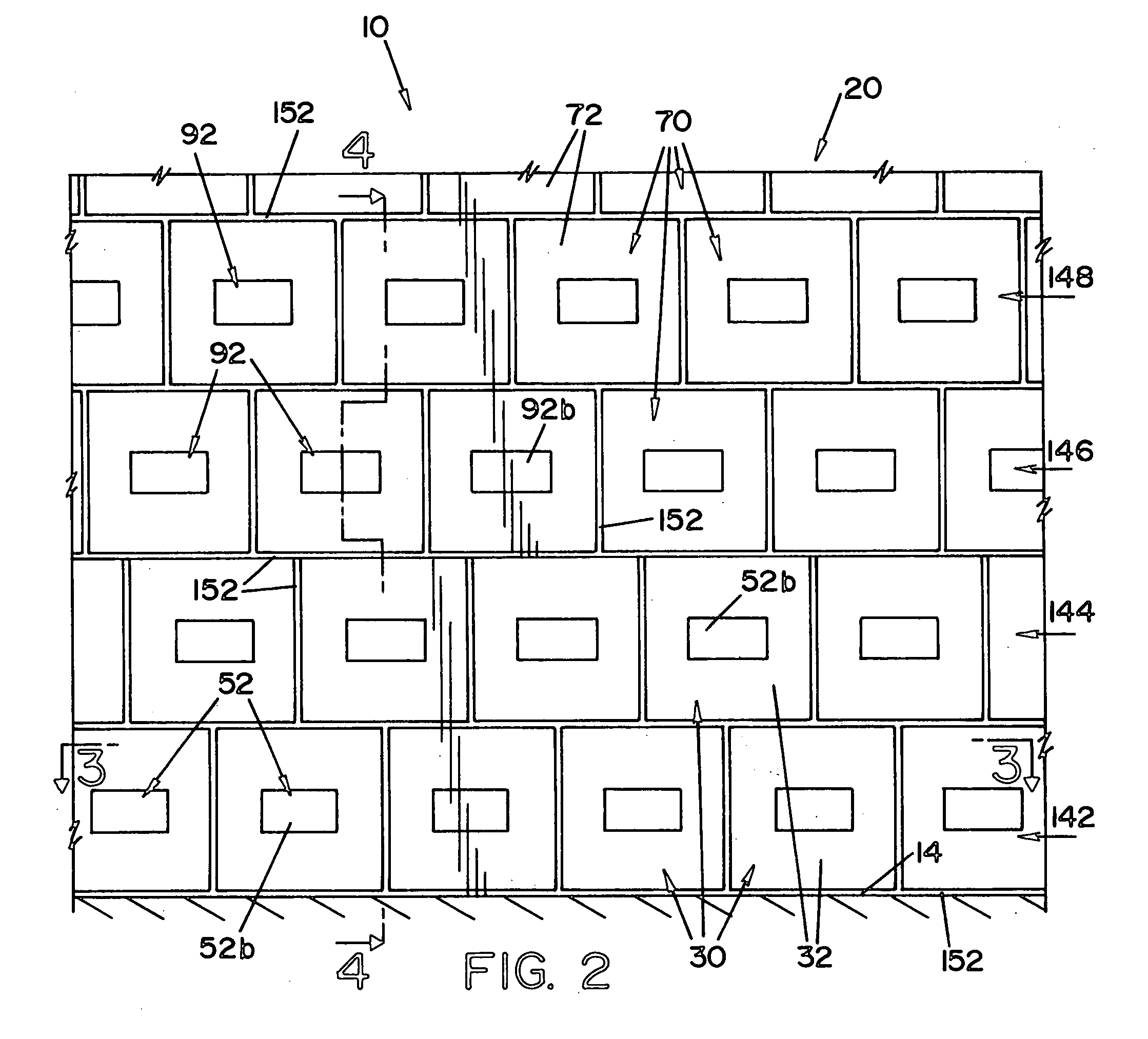

[0034] Referring now to the drawings wherein the showings are for the purpose of illustrating a preferred embodiment of the invention only, and not for the purpose of limiting same, FIG. 1 is a perspective view of a portion of a partially assembled furnace wall structure 10, illustrating a preferred embodiment of the present invention. Furnace wall structure 10 depicted in the drawings shows a refractory wall structure for use in a “clinker cooler” that cools hot clinker as it exits a furnace, such as a rotary kiln (not shown).

[0035] Furnace wall structure 10 is comprised of a refractory wall 20 and a metallic panel 100 that form the outer shell of the cooler structure. Refractory wall 20 is formed from refractory blocks 30, 70. In the embodiment shown, refractory wall 20 is comprised of two different refractory blocks, as shall be described in greater detail below.

[0036] Refractory wall 20 is spaced from metallic panel 100 to define a gap or space “X” therebetween, best seen in F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| refractory | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com